How do public ev charging stations work

How do public EV charging stations work?

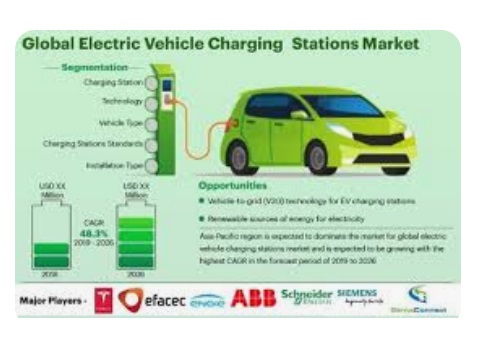

Public electric vehicle (EV) charging stations primarily achieve power conversion and vehicle charging through the following core modules:

Core Working Principle

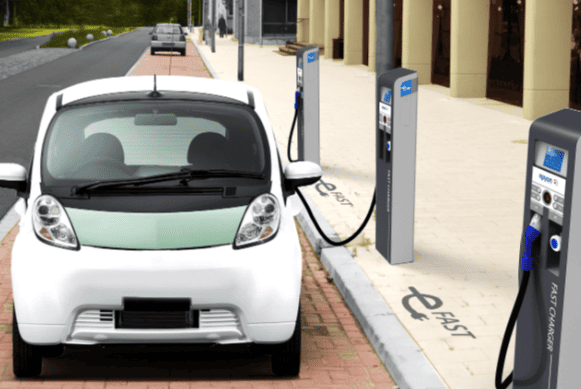

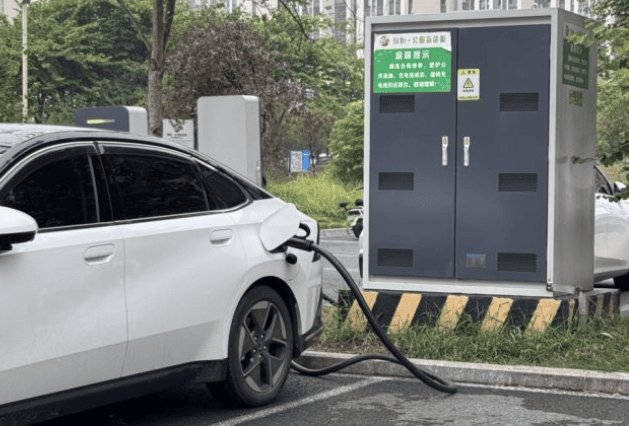

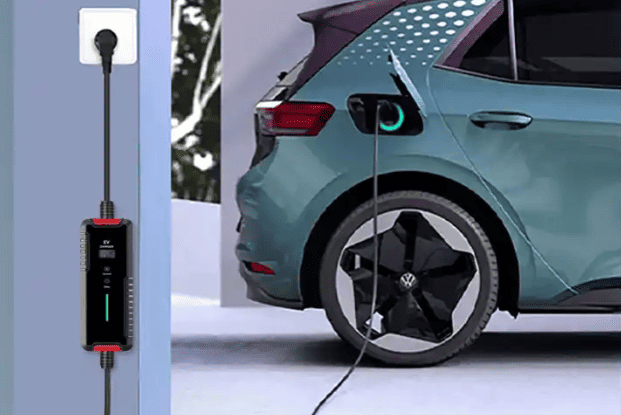

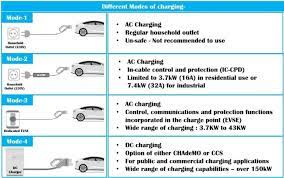

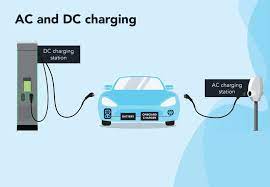

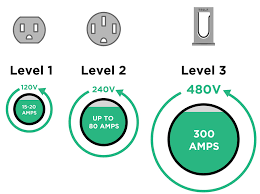

Charging piles are controllable power conversion devices, mainly divided into two types: AC charging piles (slow charging) and DC charging piles (fast charging).

- AC charging piles output 220V/380V AC power and rely on the vehicle’s onboard charger (OBC) to complete the AC-to-DC conversion.

- DC charging piles have built-in high-power AC-DC modules that directly output 200-1000V high-voltage DC power, supporting charging up to 80% of the battery in about 30 minutes.

System Architecture

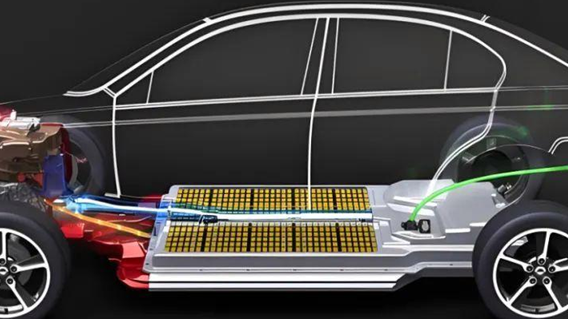

Starting from the grid input, power is transmitted through modules like EMI filtering and AC/DC conversion via the DC bus. The control core is connected to the metering unit and human-machine interaction interface to enable information exchange and command transmission.

Charging Process

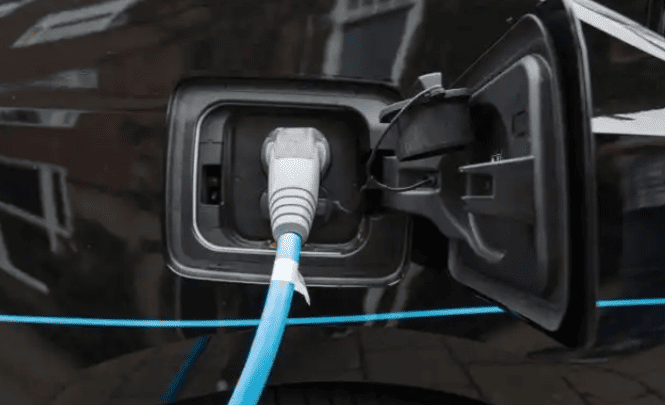

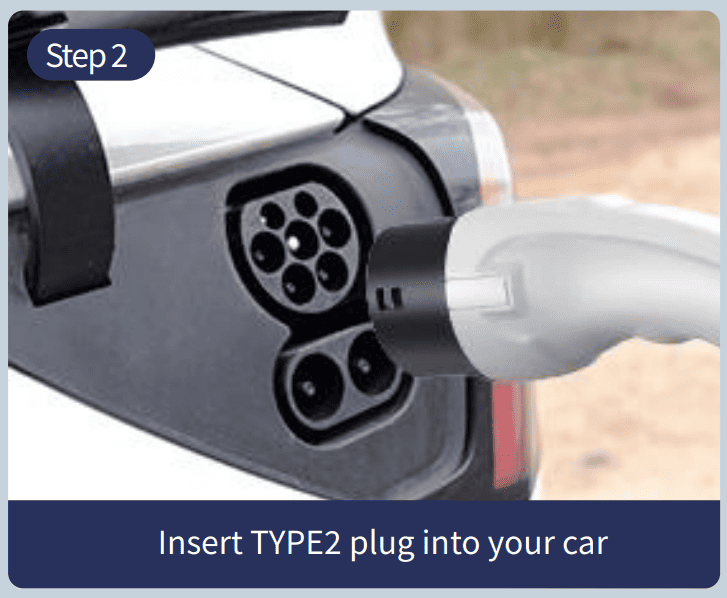

- Physical Connection: The charging gun is inserted into the vehicle’s interface, and the electronic lock activates for mechanical locking.

- Communication Handshake: The charging pile communicates with the vehicle’s Battery Management System (BMS) via PLC or CAN bus to negotiate the optimal charging curve.

- Safety Check: Insulation performance and connection impedance are detected to ensure charging safety.

Extended Services

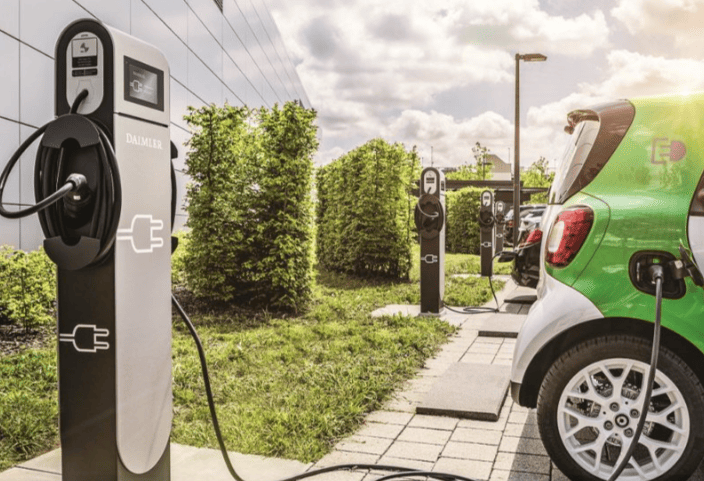

A thorough “warm harbor” service network is formed by certain public charging stations (like Shanghai iJiu Charging Baoshan Yanghang Station), which also offer extra services like driver rest areas, hot water supply, and legal advice.

Using a comprehensive process of “equipment deployment-user interaction-energy conversion-safety monitoring,” public EV charging stations are energy supply points that offer standardized charging services for various vehicle models. The following fundamental elements comprise their operational models and working principles, with particular procedures and specifics as follows:

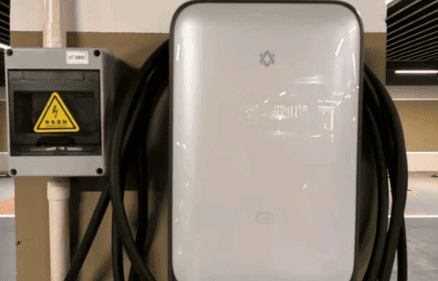

1. Core Equipment Composition: The “Hardware Foundation” of Charging Stations

The normal operation of public charging stations relies on a set of collaboratively working equipment systems. Different devices perform different functions to ensure a smooth charging process:

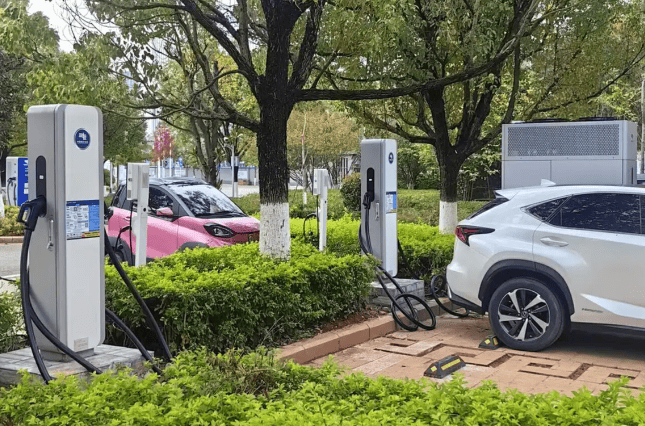

- Charging Pile Unit: The core function is to output electrical energy, divided into AC piles (slow charging) and DC piles (fast charging). For power conversion, AC piles use the car’s onboard charger, which usually has a 7kW–22kW power output. An average electric car can be fully charged in 6–12 hours, which makes it appropriate for long-term parking situations (like malls or residential parking lots). High-power rectification modules installed in DC piles directly transform grid AC power into DC power for the car’s battery. They can produce 60kW to 240kW of power, and some ultra-fast charging piles can produce 480kW or more.These can charge a battery from 20% to 80% in about 30 minutes and are commonly used in locations where quick energy replenishment is needed, such as highway service areas and transportation hubs.

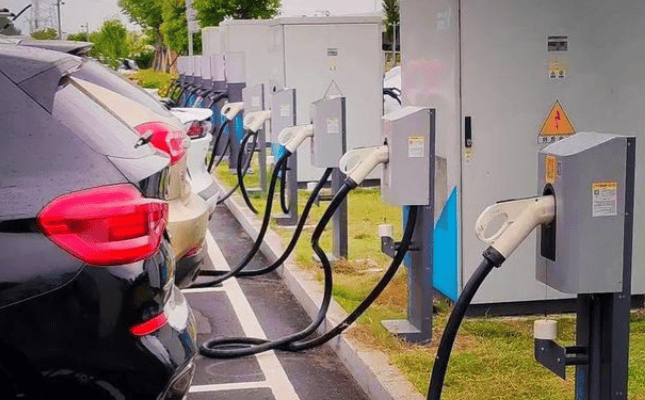

- Power Distribution System: Stepping down and distributing high-voltage electricity from the grid—usually 10kV industrial electricity—to every charging pile is the responsibility of this system. It consists of cables, distribution cabinets, transformers, and other equipment. Energy storage batteries that store electricity during off-peak grid hours and release it during peak hours are another feature that large charging stations may have. In addition to lowering the grid load, this also acts as a backup power source to keep basic charging capabilities operational during blackouts.

- Control and Communication System: Acting as the “brain” of the charging station, this system connects all charging piles via Internet of Things (IoT) technology. It collects real-time data such as charging voltage, current, and power and interacts with the backend management platform. It also supports communication methods like 4G/5G and WiFi to ensure that user commands (e.g., start/stop charging) are transmitted quickly. This enables remote monitoring of equipment status by operators.

- Safety Protection Devices: Each charging pile is equipped with leakage protectors, overvoltage/overcurrent protectors, lightning protection modules, and more. If abnormalities such as leakage, short circuits, or battery overheating are detected, the power supply is automatically cut off within 0.1 seconds to prevent equipment damage or safety incidents. Some high-end charging piles also feature “charging gun anti-misdrawal” functionality, where the gun head automatically locks during charging and can only be removed after charging has stopped.

2. User Charging Process: Standardized Operations from “Scanning” to “Unplugging”

The user interaction process at public charging stations is highly standardized. Whether for individual users or commercial vehicles (e.g., ride-hailing or taxis), charging can be completed in simple steps, detailed as follows:

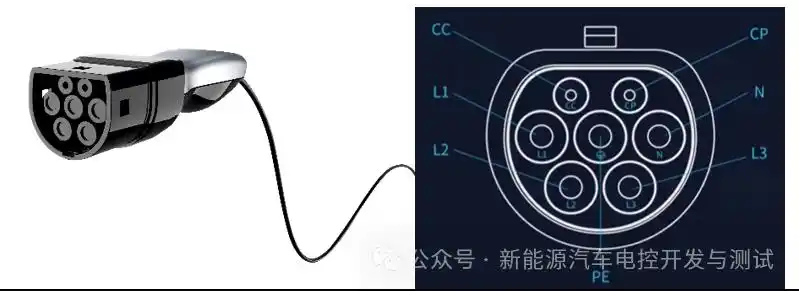

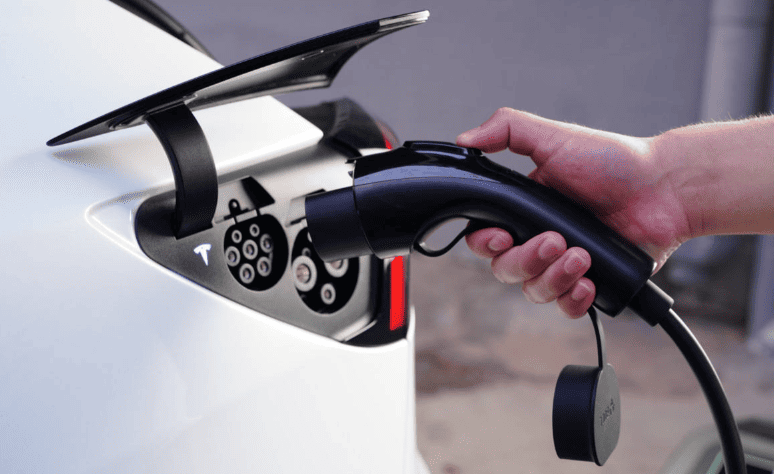

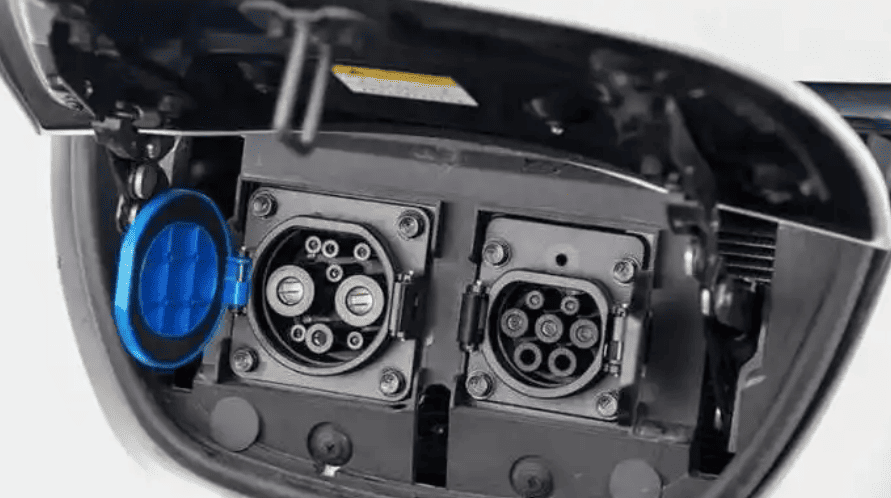

- Vehicle Parking and Preparation: The user drives the electric vehicle into the charging station and parks next to the corresponding charging pile based on the vehicle’s charging interface type (commonly the Chinese national standard GB/T 20234, with “seven-pin interfaces” for AC piles and “nine-pin interfaces” for DC piles). The vehicle’s power is turned off, the charging port cover is opened, and any dust or moisture around the interface is cleaned to prevent poor contact.

- Identity Verification and Charging Initiation: The mainstream operation method is “scan-to-charge.” Users scan the QR code on the charging pile using the charging station’s official app, WeChat, or Alipay mini-programs to complete identity verification (some may require binding a phone number or vehicle information). For commercial vehicles, charging can also be initiated by swiping a card (e.g., an enterprise-specific charging card) or entering the charging pile number. After selecting the charging mode (e.g., “stop when full,” “scheduled charging,” or “charge by amount”), the system sends a command to the charging pile to initiate charging preparation.

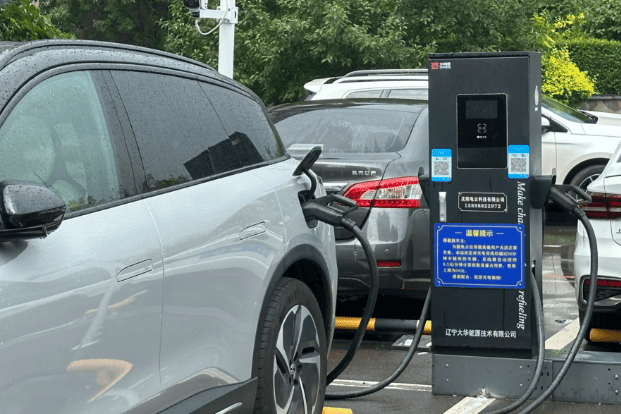

- Gun Connection and Power Transmission: The user picks up the charging gun and aligns the gun head with the vehicle’s charging interface. A “click” sound indicates successful locking (some charging piles will simultaneously light up a green indicator to signal a successful connection). At this point, the charging pile automatically detects the vehicle battery’s voltage, capacity, and state of health (SOH). After confirming compatibility, the power distribution system delivers electricity to the charging pile, where it is rectified and transformed before being input into the vehicle’s battery. AC piles output 220V/380V AC power, which is converted to DC power by the vehicle’s onboard charger. DC piles directly output high-voltage DC power, bypassing the onboard conversion process, resulting in higher charging efficiency.

- Charging Process Monitoring: During charging, the charging pile’s display screen and the user’s mobile app show real-time charging data, including current charging power, energy delivered, remaining time, and the battery’s current state of charge (SOC). The backend system simultaneously monitors current and voltage stability. If abnormalities such as excessively high battery temperature (e.g., over 45°C) or poor contact due to a loose gun head are detected, the protection mechanism is triggered immediately. Charging is paused, and a notification is sent to the user’s phone.

- Charging Completion and Settlement: When the battery reaches the set energy level (e.g., 100%) or the user-defined charging time/amount, the charging pile automatically stops supplying power, and the gun head unlocks. The user unplugs the charging gun and returns it to its place, closes the vehicle’s charging port cover, and completes the payment via the mobile app (supported methods include WeChat, Alipay, or charging card balances). Some charging stations also support “seamless payment,” where bound payment methods are automatically debited without manual operation.

3. Operation and Management: Ensuring Efficient and Safe Charging Station Performance

Public charging stations are not “install-and-forget” systems. They require professional management by operators to maintain long-term stable service. Core management aspects include:

- Equipment Maintenance: Operators conduct regular inspections (typically weekly) of charging piles and power distribution systems. This includes cleaning gun head contacts, checking cable insulation layers, and testing the sensitivity of protection devices. Comprehensive maintenance is performed monthly to calibrate charging data accuracy and update charging pile firmware (to enhance compatibility with new vehicle models). If equipment malfunctions, the backend system automatically alerts maintenance personnel, who usually arrive within two hours to address the issue, ensuring a device utilization rate of ≥95% (industry standard).

- Grid Coordination: Large charging stations need to coordinate with local grid companies to avoid overloading the grid during peak hours (e.g., 17:00-21:00, when residential electricity demand is high) due to concentrated high-power charging. Some charging stations employ “smart scheduling” technology to dynamically adjust charging pile power based on grid load. For example, when grid pressure is high, the power of fast-charging piles may be reduced from 120kW to 80kW. When load is low, full power is restored. This ensures grid stability without compromising users’ basic charging needs.

- User Services: To enhance the user experience, most charging stations offer additional services, such as displaying real-time availability of charging piles on apps (to prevent users from arriving at occupied stations), providing charging progress reminders, and supporting fault reporting. Some stations are equipped with restrooms, lounges, and convenience stores to meet the needs of users during long waiting periods. For newcomers to electric vehicles, some stations also have staff on-site to provide operational guidance.

4. Safety Assurance System: Multi-Layered Protection Against Various Risks

As high-voltage electricity scenarios, public charging stations prioritize safety through a triple-layered protection system of “equipment protection + process control + emergency response”:

- Equipment-Level Protection: All charging piles comply with the national standard “Electric Vehicle Conductive Charging System – Part 1: General Requirements” (GB/T 18487.1). Their protection rating is at least IP54 (resistant to heavy rain and dust), with some outdoor piles reaching IP65 (resistant to immersion). Charging gun heads are designed to prevent accidental contact, with insulated sealing rings at the interfaces to avoid electric shocks. Charging piles are also equipped with “arc detection” modules that identify arcs generated during charging due to poor contact and immediately cut off power.

- Process-Level Control: Pre-charging “vehicle battery detection” filters out vehicles with battery faults (e.g., swollen batteries or damaged interfaces) to prevent fires during charging. During charging, the backend system collects data every 10 seconds. If a sudden current surge (indicating a possible short circuit) or voltage drop (suggesting cable damage) is detected, protection is triggered immediately. After charging, the system delays unlocking the gun head for 10 seconds to ensure residual electricity is discharged, preventing sparks during unplugging.

- Emergency-Level Response: Charging stations are equipped with fire extinguishers (dry powder or CO2 types, suitable for electrical fires), emergency lighting, and emergency stop buttons (which can cut off the entire station’s power when pressed). Operators regularly conduct fire drills, and staff are trained in electrocution first aid and firefighting skills. In the event of a serious incident (e.g., a battery fire), the station immediately coordinates with fire departments and notifies nearby users via app to avoid the danger zone.

In conclusion, public EV charging stations are intricately linked “hardware + software + services” systems. Through multi-layered safety protections and operational management, they provide convenient and dependable energy replenishment services while relying on standardized equipment and processes to ensure efficiency. They are essential pieces of infrastructure that help new energy vehicles become widely used.