What is a charging pile?

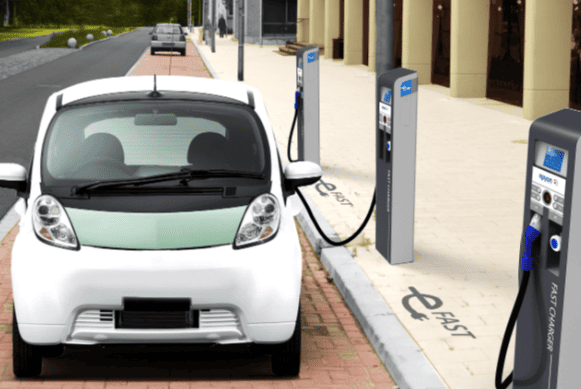

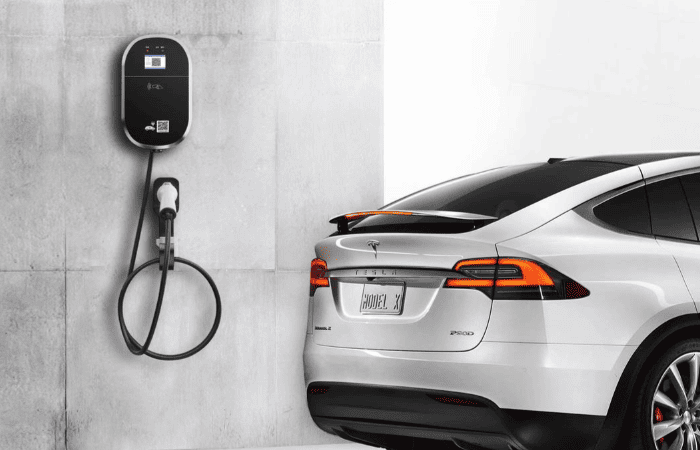

What is a charging pile? Charging pile is a replenishing device that provides electricity for electric vehicles. Its function is similar to the refueling machine in the gas station, which can be fixed on the ground or the wall, installed in public buildings (charging stations, shopping malls, public parking lots, etc.) and residential parking lots, and can charge various models of electric vehicles according to the adjustment of voltage and current.

The input end of the charging pile is directly connected to the AC power grid, and the output end is equipped with a charging plug for charging electric vehicles. Charging piles generally provide two charging methods: conventional slow charging and fast charging. People can use a specific charging card to swipe the card on the human-computer interactive interface provided by the charging pile to carry out the corresponding charging operation and cost data printing. The charging pile display screen can display the charging amount, cost, charging time and other data.

Function of Charging Pile:

By the end of June 2023, more than 6.6 million charging piles of all kinds have been built in China.

The charging pile can realize timing, metering and amount charging, and can be used as a public power purchase terminal. At the same time, in order to improve the efficiency and practicality of public charging piles (plugs), the functions of multi-charging and charging for electric bicycles will be added one after another in the future.

Charging Pile History:

The official China announced that Tesla’s full-scenario charging network in mainland China is open and upgraded, and that the home charging product series, destination charging stations, and super charging stations support more non-Tesla vehicles. On December 23, according to NIO’s official blog, NIO released a 640kW fully liquid-cooled ultra-fast charging pile and fourth-generation replacement, and will begin full deployment in April 2024. Throughout 2024, NIO will add 1,000 new seat replacement markets in China, bringing the total to more than 3,310 power stations; it will add 20,000 new charging piles, bringing the total to more than 41,000.

On March 11, 2024, the China Charging Alliance released data showing that there were 44,000 more public charging piles in February 2024 than in January 2024, a year-on-year increase of 51.2% in February. As of February 2024, member units within the alliance have reported a total of 2.826 million public charging piles, including 1.239 million DC charging piles and 1.586 million AC charging piles. From March 2023 to February 2024, an average of about 80,000 new public charging piles will be added every month.

On May 6, 2024, Weilai announced that in April 2024, 14 new power swap stations were added, bringing the total number of power swap stations to 2,411; 292 new charging piles were added, and the total number of charging piles was 22,092.

On May 25, 2024, according to Kuai Technology News, as of the end of April, the number of public charging piles across China reached 2.9766 million. Judging from the average monthly increase of 60,000+ in 2024, it has exceeded 3 million. Among them, Guangzhou exclusively owns 575,600 public charging piles, with a share of nearly 1/5 approaching saturation.

Types of Charging Pile:

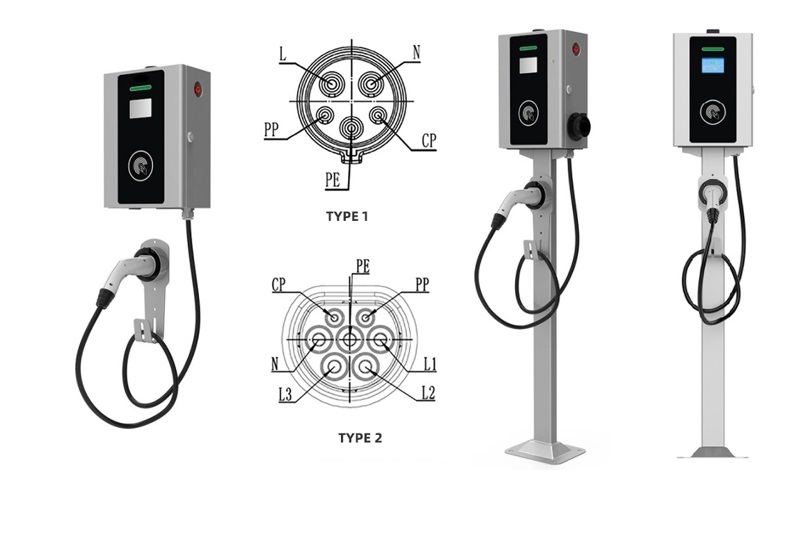

According to installation method

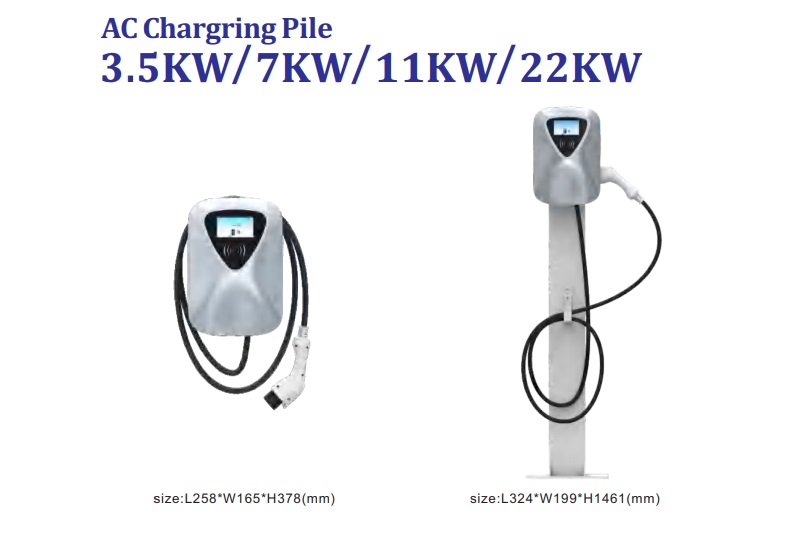

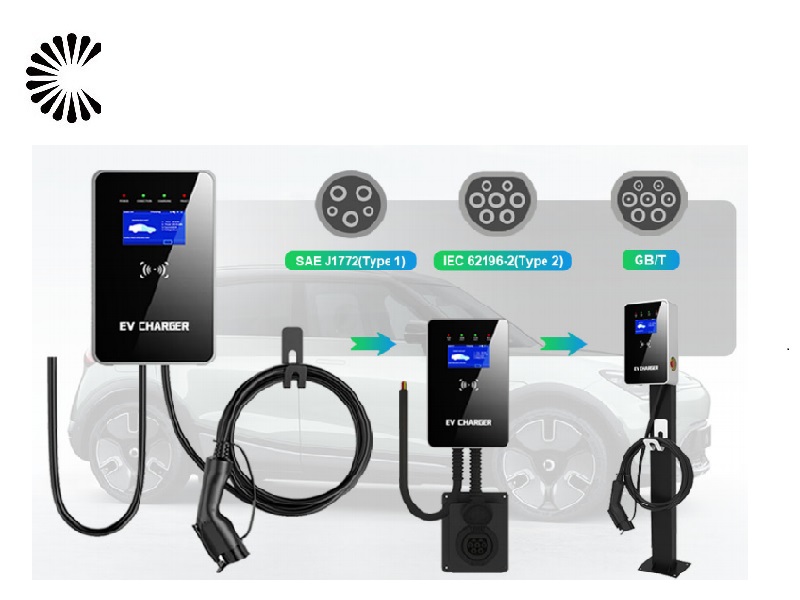

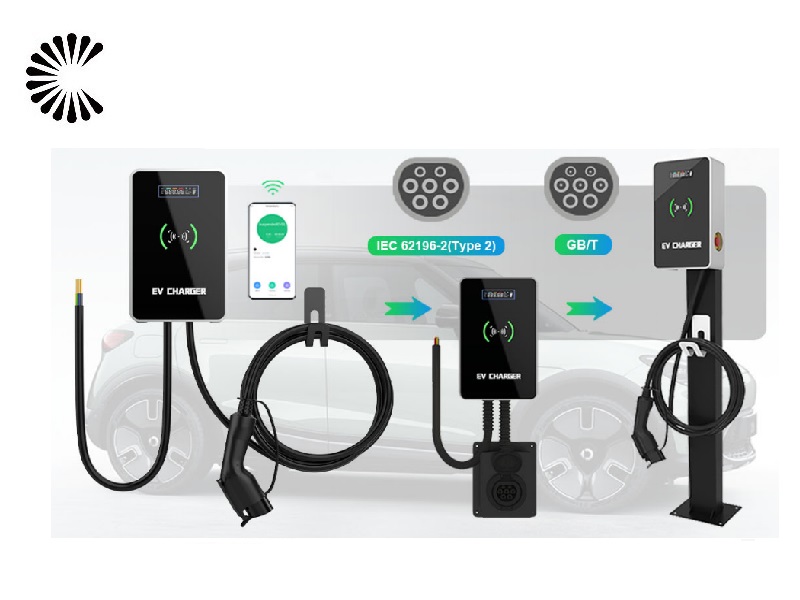

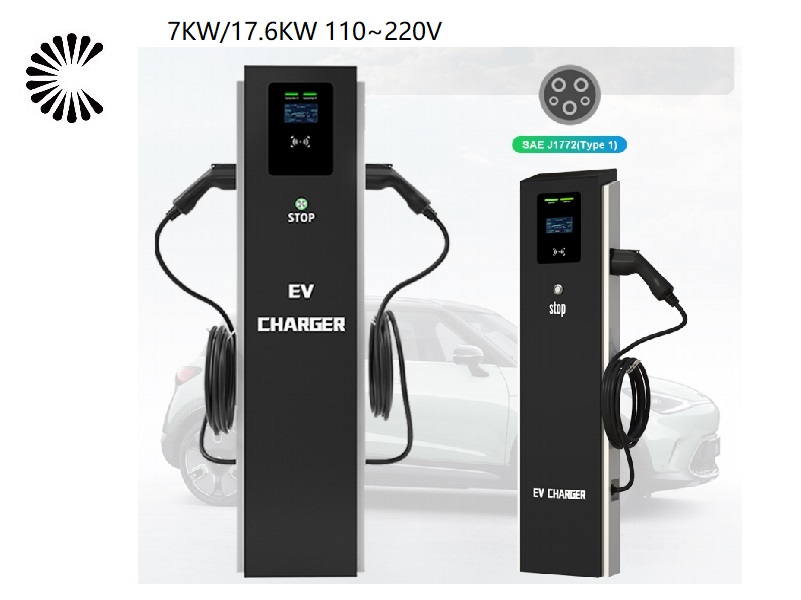

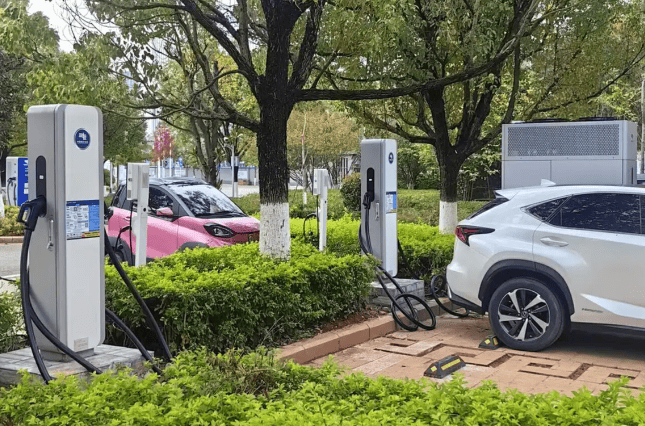

It can be divided into floor mounted charging piles and wall-mounted charging piles. Floor mounted charging piles are suitable for installation in parking spaces not close to walls. Wall-mounted charging piles are suitable for installation in parking spaces close to the wall.

According to installation location

According to the installation location, it can be divided into public charging piles and dedicated charging piles. Public charging piles are charging piles built in public parking lots (garages) combined with parking spaces to provide public charging services for social vehicles. Special charging piles are charging piles that are owned by the construction unit (enterprise) in its own parking lot (garage) and are used by internal personnel of the unit (enterprise). Self-use charging piles are charging piles built in personal parking spaces (garages) to provide charging for private users. Charging piles are generally constructed in conjunction with parking spaces in parking lots (garages). The protection level of charging piles installed outdoors should not be lower than IP54. The protection level of charging piles installed indoors should not be lower than IP32.

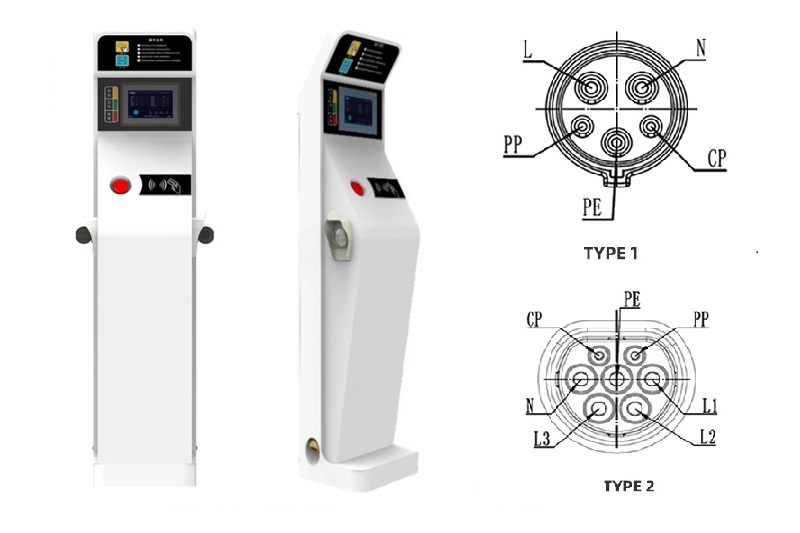

Points by charging interface

It can be divided into one-to-one charge and one-to-multiple charge.

According to charging method

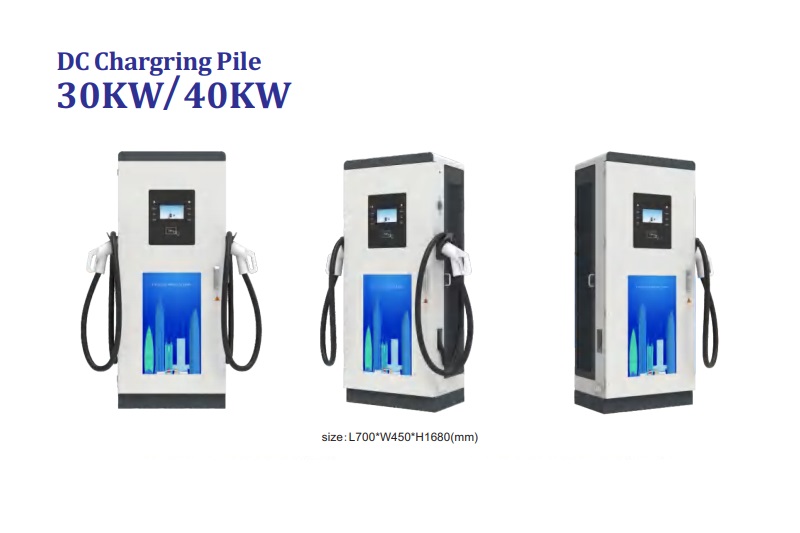

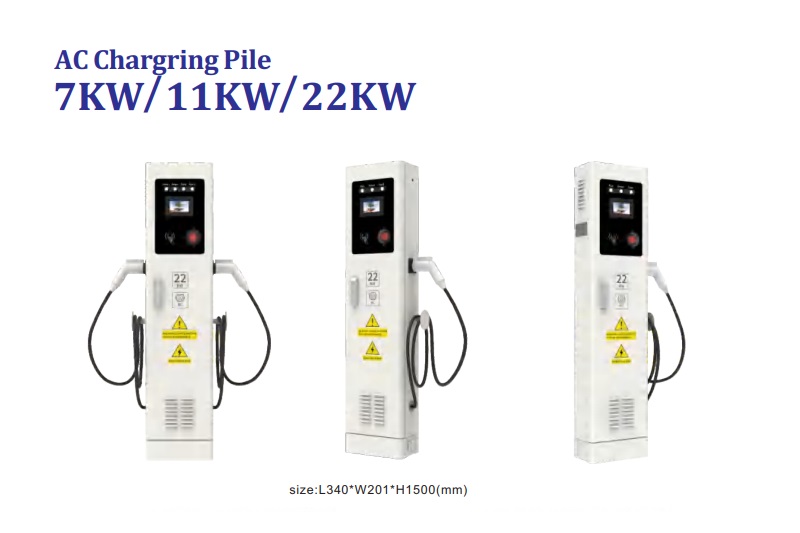

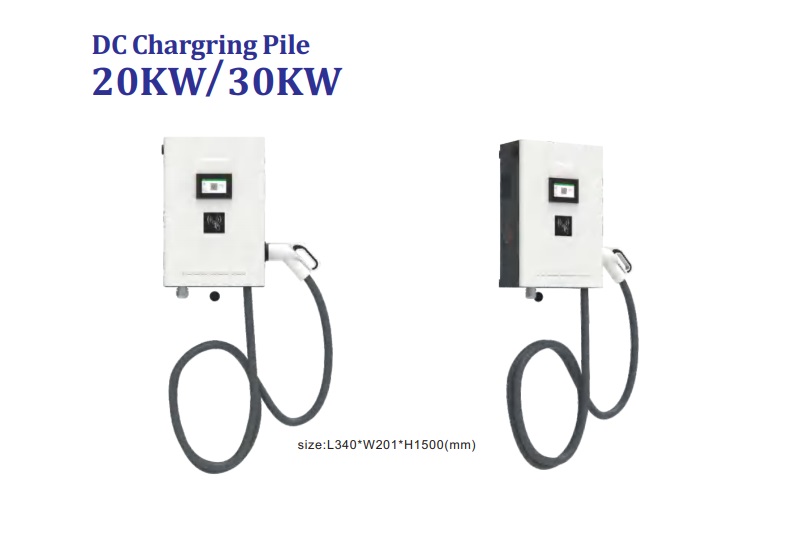

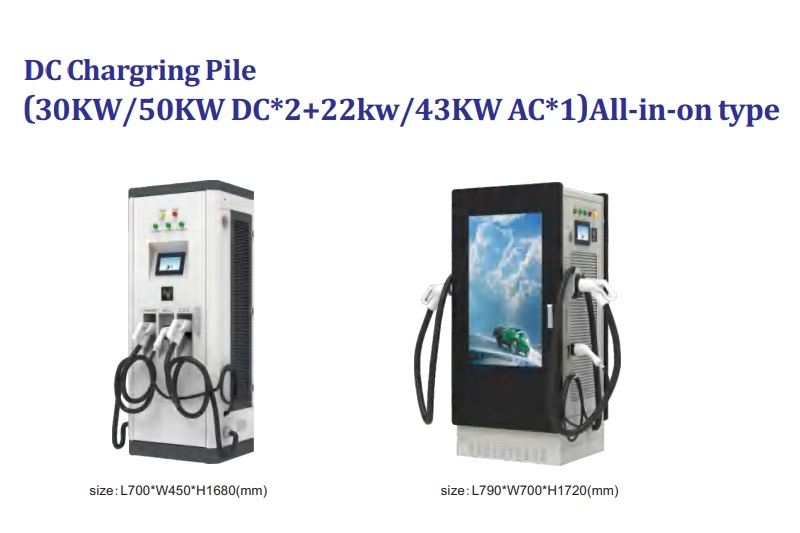

Charging piles can be divided into DC charging piles, AC charging piles and AC-DC integrated charging piles .

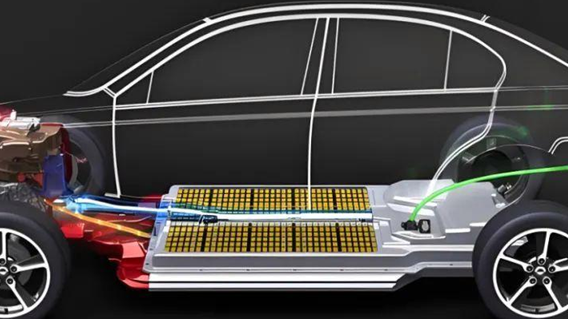

Technological realization of Charging Pile:

As the energy supply device of electric vehicle, the charging performance of electric vehicle charging pile is related to the service life and charging time of battery pack. This is also one of the problems that consumers are most concerned about before buying an electric vehicle. The realization of fast, efficient, safe and reasonable power supply of the power battery is the basic principle of the design of the electric vehicle charger, in addition, the applicability of the charger to various power batteries should be considered.

Fast charger control system composition:

Fast charger control system

Intelligent variable pulse charging mode is adopted, that is, charging current pulse is adopted, including charging pulse T1 intermittent pulse T2 and discharge pulse T3.

The charger scheme in the ground charging station

The charger in the ground charging station is composed of a rectifier that can convert the input alternating current into direct current and a power converter that can adjust the direct current power. By inserting the plug with a wire into the matching socket on the electric vehicle, the direct current energy is input to the battery to charge it. The charger is equipped with a locking lever to facilitate insertion and removal of the plug, and the lever also provides a signal to confirm that it has been locked to ensure safety. According to the communication between the charger and the battery management system on the car, the power converter can adjust the DC charging power online, and the charger can display the charging voltage, charging current, charging amount and charging cost. This is only the basic principle of the charging pile, and many details should be continuously improved in practical applications, and the most convenient use scheme has been obtained.

Construction Requirement of Charging Pile:

As an electric vehicle charging pile on the power distribution side of the power grid, the particularity of its structure determines the characteristics of the automated communication system, which is characterized by many measured points and scattered, wide coverage and short communication distance. And with the development of the city, the network topology requires a flexible and extensible structure, therefore, the selection of electric vehicle charging pile communication mode should consider the following issues:

- (1) The reliability of communication – the communication system should withstand the test of harsh environment and strong electromagnetic interference or noise interference for a long time, and maintain the smooth communication.

- (2) Construction costs – under the premise of meeting reliability, comprehensive consideration of construction costs and long-term use and maintenance costs.

- (3) Two-way communication – not only to achieve the upload of information, but also to achieve the control of the amount of delivery.

- (4) Multi-service data transmission rate – With the continuous growth of terminal business volume in the future, the communication between the master station to the sub-station and the sub-station to the terminal requires higher and higher data transmission rate to achieve multi-service.

- (5) Flexibility and scalability of communication — Due to the characteristics of multiple, wide and dispersed control points of charging piles (plugs), standard communication protocols are required. With the development of “ALL IP” network technology and the continuous growth of power operation business, IP-based service bearing needs to be considered. At the same time, it is required to facilitate installation, construction, commissioning, operation and maintenance.

Technical requirements

Ac-flow

Ac charging pile (peg) technical requirements

- Environmental requirements

- ① Working environment temperature: -20℃ ~ +50℃;

- ② Relative humidity: 5% ~ 95%;

- ③ Altitude: ≤1000m;

- ④ Installation location: outdoor;

- ⑤ Seismic capacity: ground horizontal acceleration 0.3g;

- Ground vertical acceleration 0.15g;

- The equipment should be able to withstand three sine waves at the same time, and the safety factor should be greater than 1.67;

- Structural requirements

- ① The shell of AC charging pile (bolt) should be strong;

- ② The structure must prevent the hand from easily touching the exposed part;

- ③ AC charging pile (bolt) should choose a steel combination structure with a thickness of more than 1.0, the surface is impregnated with plastic, and the requirements of heat dissipation are fully considered. The charging pile (bolt) should have a good shielding function against electromagnetic interference;

- (4) The charging pile (bolt) should have sufficient support strength, and the necessary facilities should be provided to ensure that the equipment can be correctly lifted, transported, stored and installed, and the anchor bolt holes should be provided;

- ⑤ The bottom of the pile (bolt) body should be fixed on the base which is not less than 200mm above the ground. The base area should not be greater than 500mm×500mm;

- ⑥ The shell of the pile (bolt) body should be made of materials with strong impact resistance, good anti-theft performance and anti-aging.

- The non-insulating material shell should be reliably grounded;

- Power requirements

- ① Input voltage: single-phase 220V;

- ② Output power: single-phase 220V/5KW;

- ③ Frequency: 50Hz±2Hz;

- ④ The allowable voltage fluctuation range is: single-phase 220V±15%;

- Electrical requirements

- ① After the correct connection between the plug and the socket is confirmed, the load can be disconnected circuit can be closed to realize the power supply to the socket;

- ② The leakage protection device should be installed on the inlet side of the power supply cable;

- ③ The protection of low-voltage distribution equipment and lines should meet the relevant provisions in the “Low-voltage Distribution Design Code” (GB/50053);

- (4) For the IT system distribution line, when the first grounding fault, the insulation monitoring device should send a sound or light signal, when the second out-of-phase grounding fault occurs, the fault circuit should be cut off by the overcurrent protection appliance or leakage current action protector;

- ⑤ In the lighting distribution system, the lighting and socket circuits should not be powered by the same circuit. The power supply side of the socket circuit should be equipped with residual current action protection device, whose rated action current is 30mA;

- Security protection function

- ① AC charging pile (bolt) should have emergency stop switch, can be manually or remote communication emergency stop charging;

- ② AC charging pile (bolt) should have leakage protection function on the output side;

- (3) AC charging pile (bolt) should have the output side current and short circuit protection function;

- ④ AC charging pile (bolt) should have flame retardant function;

- 6.IP protection level

Ac charging pile (peg) should comply with IP54 (outdoor), and equipped with necessary rain and sun protection devices;

- Three anti-moisture, anti-mildew, anti-salt spray protection

The printed circuit board, connector and other circuits in the charger should be treated with anti-dampness, anti-mildew and anti-salt spray, among which the anti-salt spray corrosion capability meets the requirements of Table 9 in GB/T 4797.6-1995 “Natural Environmental Conditions of Electrical and Electronic Products Dust, sand and salt spray”, so that the charging function can operate normally in outdoor humid environment with salt spray.

- Anti-rust (anti-oxidation) protection

The iron shell of the charging pile (bolt) and the exposed iron bracket and parts should be double-layer anti-rust measures, and the non-iron metal shell should also be equipped with anti-oxidation protective film or anti-oxidation treatment;

- Wind protection

The charger installed on the platform and the exposed parts should be able to withstand the invasion of the relative wind speed at different regions and different heights specified in Table 9 of GB/T 4797.5-9 “Precipitation and Wind in Natural Environmental Conditions of Electrical and Electronic Products”;

- Burglar protection

The shell door of electric pile (bolt) should be equipped with anti-theft lock, and the bolts fixing the AC charging pile (bolt) must be installed or removed after opening the shell door;

- Temperature rise requirements

The AC charging pile (peg) shall run continuously at the rated load for a long time, and the temperature rise of the internal heating components and various parts shall not exceed the requirements of Table 2 in Q/GDW 397\2009;

- Mean Time between Failures (MTBF)

MTBF should not be less than 8760h;

- Installation vertical inclination does not exceed 5%;

- The installation site of the equipment shall not contain explosive dangerous media, and the surrounding media shall not contain harmful gases and conductive media that corrode metal and destroy insulation

DC straight flow

a) Charging pile power supply input voltage: three-phase four-wire 380VAC±15%, frequency 50Hz±5%;

b) The charging pile should meet the charging object;

c) The output of the charging pile is direct current, and the output voltage meets the battery standard requirements of the charging object;

d) The maximum output current meets the charging requirements of the battery standard 1C of the charging object, and is backward compatible;

e) The charging mode is divided into conventional and fast, the conventional is 5-hour charging mode, and the fast is 1-hour charging mode (selected for different battery types);

f) Realize intelligent IC management;

g) Each charging pile (bolt) comes with an operator to provide users with charging mode selection and operation guidance, and displays electric vehicle battery status and user IC card fee information to achieve unmanned management;

h) The charging pile (bolt) interface shall comply with the relevant provisions of the DC charging interface of GB/TXXXXXXXX electric vehicle conduction charging interface (temporary);

i) The communication interface of charging pile (peg) adopts CAN communication interface, and the communication protocol shall be implemented in accordance with the (interim) communication protocol between GB/TXXXXXXXX electric vehicle battery management system and non-vehicle charger (charging object is lithium battery electric vehicle);

j) The charging pile should have corresponding alarm and protection functions for the abnormal state during the charging process;

k) The charging pile should monitor the status of the battery and automatically adjust the charging curve, charging current and charging voltage according to the temperature and voltage of the battery;

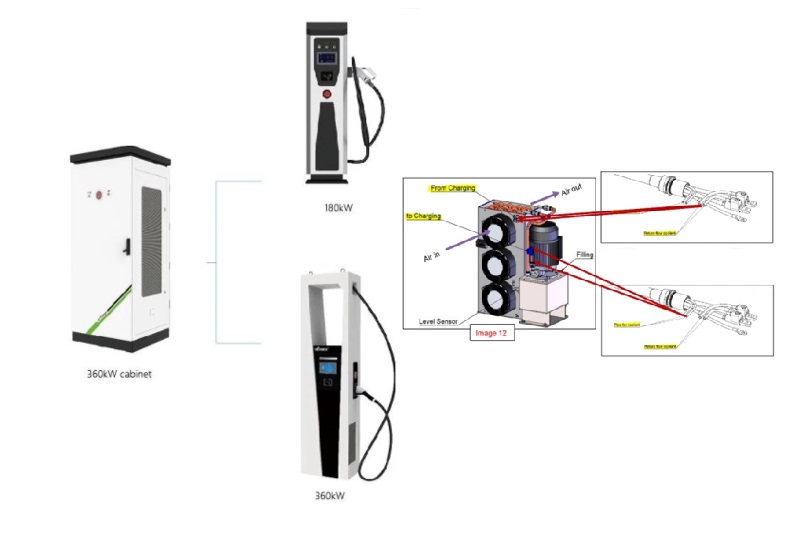

l) The charging pile adopts forced air cooling;

m) The protection level of charging pile (bolt) meets the IP54 requirements of “GB 4208-1993 Shell Protection Level (IP Code)”;

Integrated Type Charging Pile

summarize

Fast charging pile (peg) equipment adopts AC/DC integrated structure. Both DC charging and AC charging can be realized. When there are many charging services during the day, DC mode is used for fast charging, and AC charging can be used for slow charging operation when there are few users at night charging station.

Contour feature

- Ergonomic design, fully considering the characteristics of Chinese people, after the installation of the machine height, screen height, keyboard height, charging joint placement slot height, suitable for operation;

- The upper outlet form saves half of the operator’s physical strength;

- Considering people’s use habits and durability, the touch screen and keyboard are controlled by mutual backup, and the touch screen and keyboard are designed to prevent rain and dust.

- Emergency stop switch with emergency stop; Equipped with charging joint placement slot, placing slot can be waterproof; 5 meters of flexible cable.

Functional characteristics

- Provide human-machine interactive operation; Provide DC, AC charging interface;

- With voice prompt function; With credit card function;

- With the function of printing vouchers;

- Communicate with BMS in real time to obtain power battery type, unit voltage, remaining capacity, temperature, alarm and other information;

- Generate control instructions and switch signals to the charger, control the start and stop of the charger, and obtain the status information of the charger;

- Complete security protection control logic such as connection state judgment, interlock and control guidance of charging interface;

- With CAN2.0B, RS485 communication interface, can communicate with centralized monitoring, send charging status information;

- With leakage, short circuit, overvoltage, undervoltage, overcurrent and other protection functions to ensure the safe and reliable operation of the charging pile (peg); Protection class IP54.

Charging technology

Since the first electric vehicle was introduced in the 19th century, rechargeable batteries have been used as its power source. For an electric vehicle, battery charging equipment is one of the indispensable subsystems. Its function is to convert the electrical energy of the grid into the electric energy of the on-board battery of the electric vehicle. There are different ways to classify electric vehicle charging devices, which can be generally divided into vehicle charging devices and non-vehicle charging devices.

The vehicle charging device refers to the device installed on the electric vehicle using the ground AC power grid and the vehicle power supply to charge the battery pack, including the vehicle charger, the vehicle charging generator set and the operation energy recovery charging device, and the AC power cable with a plug is directly inserted into the charging socket of the electric vehicle to charge the battery. The vehicle charging device usually uses a contact charger with simple structure and easy control, or it can be an inductive charger. It is completely designed in accordance with the types of vehicle batteries, and it is highly targeted. Non-vehicle charging devices, that is, ground charging devices, mainly include special charging machines, special charging stations, general charging machines, charging stations for public places, etc. It can meet a variety of battery charging methods. Usually, the power, volume and weight of non-vehicle chargers are relatively large, so that they can adapt to various charging methods.

In addition, according to the different ways of energy conversion when charging the electric vehicle battery, the charging device can be divided into contact and induction. With the rapid development of power electronics technology and converter control technology, and the maturity and popularization of high-precision controllable converter technology, the phased constant current charging mode has been basically replaced by the constant voltage current limiting charging mode with continuous change of charging current and charging voltage. The dominant charging process is the constant voltage and current limiting charging mode. The biggest problem with contact charging is its safety and versatility. In order to make it meet the strict safety charging standards, many measures must be adopted on the circuit to make the charging device can be safely charged in various environments, constant voltage limited current charging and phased constant current charging are contact charging technology. The new inductive charging technology for electric vehicles is developing rapidly. The induction charger uses the transformer principle of high-frequency AC magnetic field to induce the electric energy from the original side of the car to the secondary side of the car to achieve the purpose of charging the battery. The biggest advantage of inductive charging is safety, because there is no direct point contact between the charger and the vehicle, even if the vehicle is charged in bad climates, such as rain and snow, there is no risk of electric shock.

Safety requirements:

- (1) The substation shall set up safety barriers, warning signs, safety lights and alarm bells.

- (2) The “Stop, high voltage danger” warning sign should be hung on the safety column outside the high voltage distribution room and transformer room or substation. Warning signs must be directed towards the outside of the fence.

- (3) There should be significant operating instructions on the high-voltage distribution device. The ground point of the equipment shall be clearly marked.

- (4) There should be a clear “safe passage” or “safe exit” sign.

- In addition, the layout design of the substation and distribution equipment should be convenient for installation, operation, handling, maintenance, testing and monitoring. High and low voltage distribution room, transformer room, capacitor room, control room, should not have unrelated pipelines and lines through. Of course, even if the technical bottleneck of the charging station has been well solved, there may still be problems such as location difficulties in the construction of the charging station. New energy vehicles should first be mainly in cities, but the busy area of IX is often land shortage, land price cost is high, in this regard, the government needs to be inclined in policy. Promote the construction of charging facilities. Electric power enterprises have inherent advantages in developing and operating electric vehicle charging stations. Power companies selling electricity directly to vehicles is a new business, and it is hoped that power companies will change.

Communication mode:

The electric vehicle charging pile belongs to the distribution network side, and its communication mode is often comprehensively considered together with the distribution network automation. Communication is a key and difficult point of distribution network automation, different regions, different conditions, the applicable communication methods are also different, specific to electric vehicle charging pile, its communication methods mainly include wired and wireless:

(1) Wired mode

The main wired modes are: wired Ethernet (RJ45 cable, optical fiber), industrial serial bus (RS485, RS232, CAN bus).

The main advantages of wired Ethernet are reliable data transmission and large network capacity, while the disadvantages are complex wiring, poor expansion, high construction cost and poor flexibility.

Industrial serial bus (RS485, RS232, CAN bus) advantages are reliable data transmission, simple design, the disadvantage is complex network, poor expansion, high construction cost, poor flexibility, low communication capacity.

(2) Wireless mode

Wireless mode mainly adopts mobile data access services of mobile operators, such as: GRPS, EVDO, CDMA, etc.

The use of mobile data services by mobile operators requires the electric vehicle charging pile, an internal device of the power grid, to be connected to the mobile data network of mobile operators, which requires the payment of expensive monthly rent and annual fee, and the cost will increase with the increase of the number of charging piles. At the same time, data security and network reliability are restricted by mobile operators, which is not conducive to the safe operation of equipment. Secondly, the mobile access bandwidth of mobile operators is a shared bandwidth. When a large number of devices are accessed in a local area, the reliability of access and the average bandwidth of each user will deteriorate, which is not conducive to the intensive access of charging pile groups and the data transmission of large amounts of data.

Lean operation

Encourage parking lots and charging operation enterprises to innovate technology and management measures, guide fuel vehicles and new energy vehicles to park in separate areas, and maintain a good charging order [4]; The Beijing Municipal Bureau of Market Supervision issued the “Parking lot (Warehouse) Operation Service Specifications”, which proposed that the fuel vehicles occupying the electric vehicle parking space and the electric vehicles that have not left after charging more than one time unit can be charged by the stepped price standard, and the unit time charge shall not exceed 150% of the current charge standard of the ordinary parking space.

The maximum per hour charge will not exceed 150% of the current charge for ordinary parking Spaces

Considering the close relationship between charging and parking, the data interconnection between charging pile charging platform and global parking charging platform is established to accurately determine whether the parking vehicle in the charging pile parking space has been charged, and then the stepped price standard is adopted to charge according to the relevant provisions of Beijing’s “Parking lot (warehouse) Operation Service Specification”, which will be beneficial to improve the utilization rate of charging pile.

Policies support

Document No. 1721 of the Development and Reform Energy (2023) “Implementation Opinions of the National Development and Reform Commission and other departments on Strengthening the integration and interaction of new energy vehicles and the Grid” pointed out that

By 2025, China’s vehicle network interactive technical standard system has been initially completed, the charging peak and valley electricity price mechanism has been fully implemented and continuously optimized, and important progress has been made in the construction of market mechanisms, and more efforts have been made to carry out pilot demonstrations of vehicle network interaction. Strive to participate in the pilot demonstration of the city in 2025 annual charging capacity of more than 60% concentrated in the low period, private charging pile charging capacity of more than 80% concentrated in the low period, the potential of new energy vehicles as mobile electro–chemical energy storage resources through the pilot demonstration has been initially verified.

By 2030, China’s vehicle network interaction technology standard system is basically completed, the market mechanism is more perfect, the vehicle network interaction realizes large-scale application, intelligent and orderly charging is fully promoted, and new energy vehicles become an important part of the electrochemical energy storage system, and strive to provide the power system with 10 million kilowatts of two-way flexibility adjustment ability.

Development situation:

At present, China is at the peak of the construction of charging station infrastructure, and the government and enterprises are concerned about the choice of direct charging or replacement of professional charging station services, and the comprehensive service of domestic charging station has not been developed.

1) Successful operation of charging stations: the two largest and most mature electric vehicle charging stations in China are the Beijing Olympic Charging Station and the Shanghai World Expo Charging Station, which are currently providing rapid battery replacement services for urban electric buses, and the two charging stations are not formal commercial operations at present, but only pilot operations organized by the government. The common point of the two charging stations is that they are run by the local bus group, the charging station is established by the national major special funds and local funds, and the electric bus belongs to the bus group. The power battery used in the Beijing Olympic charging station is rented from the battery manufacturer, and the monthly rental fee is paid to the battery manufacturer according to the electricity used (about 4 yuan for 1 KWH of electricity). The Shanghai World Expo charging station directly from the battery manufacturer to buy batteries, while the battery manufacturer is responsible for the initial battery maintenance, and complete the training of relevant technicians, after the battery ownership to the charging station.

2) At present, the State Grid is speeding up cooperation with local governments to speed up the construction of charging stations. According to the plan proposed by Liu Zhenya, general manager of the State Grid Corporation at the beginning of the year, the State Grid will establish 75 public charging stations, 6,209 AC charging piles and some battery replacement stations in 27 provinces and cities (districts) during the year. The projects announced so far include the establishment of five medium-sized electric vehicle charging stations after the cooperation between State Grid Shaanxi Electric Power Company and Xi ‘an; Chengdu Provincial Electric Power Company and local government cooperation within the year to build 3 electric vehicle charging stations and 300 charging piles; Hubei Electric Power Company and Yichang City cooperate to build 1 large charging station and 16 charging piles within the year; Chongqing Electric Power Company and Chongqing to establish 50 charging piles within the year CNOOC: A joint venture with China Putian CNOOC New Energy Power Co., LTD., specializing in the operation of electric vehicle energy supply network. The joint venture has partnered with Zotye Automobile to start the construction of a network of charging stations for pure electric vehicles in more than two provincial capitals in China. Sinopec: Sinopec announced that it will enter the charging station industry for the first time with Beijing as a breakthrough. Sinopec’s Beijing Petroleum Branch and Beijing Shouke Group Co., Ltd. have jointly funded the establishment of Beijing Sinopec Shouke New Energy Technology Co., LTD., which will mainly use Sinopec’s existing large refueling and gas stations to transform into refueling and charging comprehensive service stations. Sinopec will use Beijing as a breakthrough to enter the charging station industry, and its refueling and charging integrated service station will eventually expand to the city, and then expand to Hebei, Tianjin and even greater scope. Petrochina: Reportedly contacted local government departments with the idea of building electric vehicle charging stations.

3) State Grid Corporation’s charging station investment plan: State Grid will vigorously build charging stations and charging piles in three stages. In the first stage (2010), the total investment scale of charging station main equipment will reach 300 million yuan, and 75 charging stations and 6,209 charging piles will be built in 27 network provinces, and the network architecture of electric vehicle charging facilities will be initially built. In the second stage (2011-2015), 14 billion yuan will be invested, the scale of EV charging stations will reach 4,000, and the construction of charging piles will be vigorously promoted simultaneously to initially form an EV charging network; In the third stage (2016-2020), 18 billion yuan will be invested to reach 10,000 electric vehicle charging stations, and the construction of supporting charging piles will be carried out simultaneously and comprehensively to build a complete electric vehicle charging network. By 2020, the total investment in main equipment of charging stations will reach 32 billion yuan. In 2010, the investment scale of charger, power monitoring system and active filter device in the main equipment of charging station will reach 150 million yuan, 20 million yuan and 63 million yuan respectively, and the average annual investment scale of the second stage will rapidly increase to 1.44 billion yuan, 160 million yuan and 672 million yuan. In 2010, the investment scale of charging pile was 160 million yuan, and from 2011 to 2015, the investment scale of charging pile was 4.5 billion yuan, with an average annual investment of 900 million yuan, which was 5 times the average annual investment scale of the first stage. By 2020, the total investment in charging piles will reach 12.5 billion yuan.

By the end of 2022, a total of 5.21 million charging piles and 1,973 power stations have been built across the country, of which 2.593 million new charging piles and 675 power stations will be added in 2022, significantly accelerating the construction of charging infrastructure.

By the end of 2023, a total of 21,000 charging piles have been built, and the charging infrastructure network along the highway has been further improved.

In March 2024, according to the “industrial micro news” news, in 2023, China’s new public charging pile 929,000 units, an increase of 42.7%; 2.458 million private charging piles were built with vehicles, up 26.6% year-on-year.

As of April 2024, China has built a total of 23,600 charging piles along the highway. [28]

Industry barrier

- (1) The charging current varies from 10 amps to 100 amps, which has higher requirements for high-power charging modules of charging piles.

- (2) The lithium-ion battery used in electric vehicles has strict requirements for overcharging and over discharging, and the charging device needs to be equipped with a high-precision monitoring system.

- (3) At present, the pattern of the charging station market dominated by the two major grid companies of the State Grid and the Southern Power Grid has basically taken shape, and new entrants will face higher barriers.

Investment prospect

- (1) Electric vehicles have always been regarded as the development trend of the next generation of vehicles. As a “gas station” for electric vehicles, the full development of charging pile construction will undoubtedly provide a huge market. In the three major cities of Beijing, Shanghai and Guangzhou, due to traffic congestion, car purchase restrictions have been carried out through license plates. However, due to the environmental protection role of electric vehicles, the government supports electric vehicles from the upper level, so large cities such as Beijing, Shanghai and Guangzhou have relevant policies, and the electric vehicles entering the relevant directories can directly obtain license plates, which stimulates the demand for electric vehicles from the policy aspect. At the same time, the price of domestic refined oil products is rising faster than the rate of decline, and the final owner is suffering from higher and higher oil prices, and electric vehicles can replace some gasoline and diesel consumption, reducing this part of the cost. There is no doubt that the charging pile is the terminal market for the promotion of the new energy strategy, if you can seize the opportunity now, it will be of great benefit to the profit of capital.

- (2) The government’s strong support and promotion has stimulated the expectations of many enterprises for the charging pile industry. An industry source said that in addition to energy giants such as State Grid, Southern Power Grid and Sinopec, automobile companies and electrical production enterprises are highly motivated. Electric vehicle companies such as BYD and BAIC have already begun to build general charging piles, and enterprises in the industry such as Xuji Electric and Siemens have also begun to develop or invest in the construction of charging stations. According to relevant estimates, in the next five years, the business scale of charging stations is expected to exceed 100 billion per year. From the point of view of various national actions, the charging infrastructure construction of electric vehicles will break out.

- (3) Private capital is eyeing the charging pile market. Since electric vehicles need to supplement a large amount of electricity every day, operating charging stations can reap huge benefits from charging services. Compared with gas stations, electric energy is relatively safe and convenient, and charging stations can be installed in a large number of places. According to the scale of investment, small to community slow charging pile, large to highway fast charging station, single station operation, network operation can be. For the opening of the charging station market, the State Grid may be more inclined to service and power supply in the future, so that the construction of charging stations will be more fully integrated with the market, and everyone will be a competitor in the same market. Therefore, advance preparation and planning are very important for companies engaged in battery production. The charging and replacement market, the policy is inclined, the market has potential, and the investment is less, and it will face greater business opportunities.

- (4) It will take time to achieve more substantial returns. Today, in addition to Beijing, Tianjin, Shanghai, Hangzhou and other places have introduced charging facility construction planning, many local governments have also proposed new ideas for the construction of new residential supporting charging piles, which can not only alleviate the “range anxiety” problem of electric vehicle users, but also significantly and directly stimulate the sales of charging pile manufacturers. As an important downstream pillar industry of the new energy automobile industry chain, the marketization prospects of charging piles seem to be quite optimistic. Although the industry prospects are uniformly optimistic, the current development of the electric vehicle market is not fully mature. The three major issues of standard, planning and land are blocked in front of the road of charging pile construction, and the construction of a system of charging piles is not smooth.