ev charger vs supercharger

EV Charger vs Supercharger: Powering Up Your Electric Journey

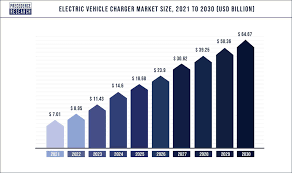

The development logic of the new energy vehicle industry chain, user charging experiences, and vehicle operating costs are all significantly impacted by the technical principles, application scenarios, and performance parameters that distinguish electric vehicle charging stations (EV chargers) from superchargers. The detailed comparison that follows examines these variations in a number of ways.

I. Technical Principles & Core Differences

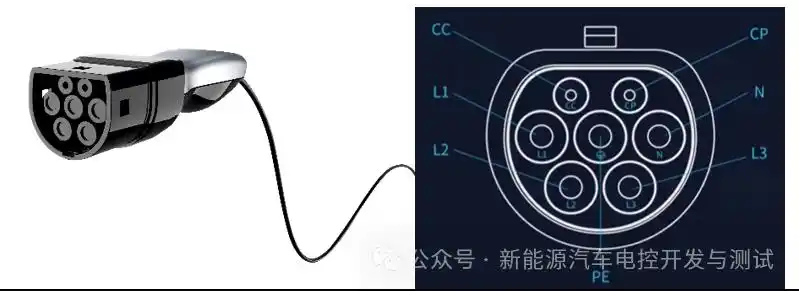

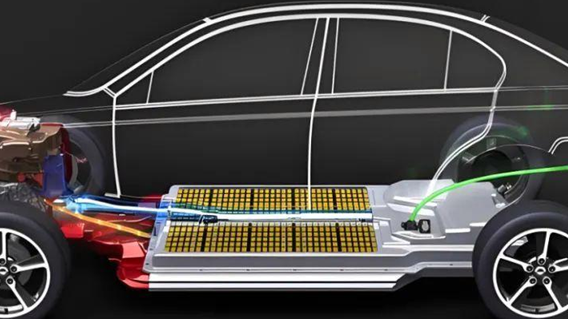

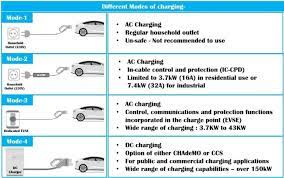

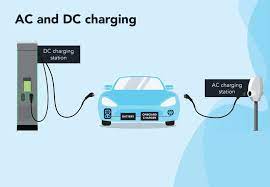

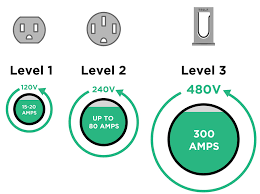

How they supply power to the car’s battery is the primary difference. Commonly referred to as “slow chargers,” standard EV chargers, which are primarily AC (alternating current) chargers, carry out a comparatively straightforward function. Their primary job is to supply the car with AC power straight from the grid. The On-Board Charger (OBC) of the car itself performs the crucial conversion from AC to DC (Direct Current) that the battery needs. Because of its relatively simple structure, which consists mainly of control modules, metering modules, and safety protection modules, the charger itself has a lower technical barrier. Its maximum power capability is solely dependent on the vehicle’s built-in charger and does not manage the intricate power conversion process. Consequently, standard chargers typically operate at common voltages like 220V (single-phase) or 380V (three-phase) with relatively small currents, resulting in limited charging power, commonly ranging from a modest 3.5kW up to around 21kW for faster home or public AC units.

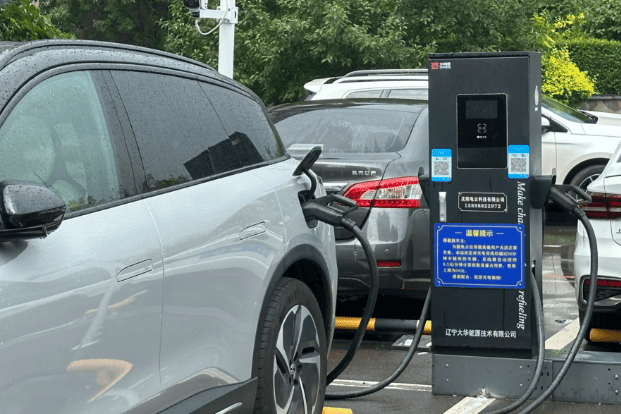

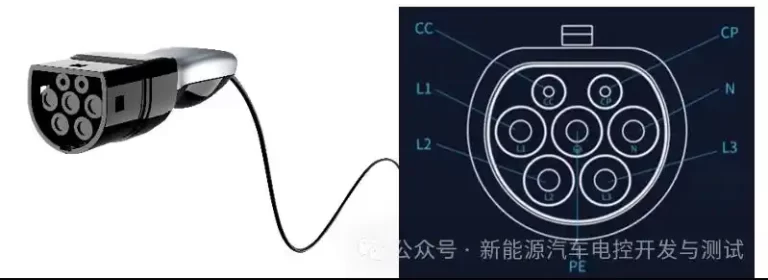

Superchargers, on the other hand, are an extremely sophisticated type of DC (Direct Current) fast charging. They serve as effective external power converters. The supercharger station itself contains enormous rectifier modules that eliminate the need for the vehicle’s internal systems. Before the AC power even reaches the car, these modules transform it into high-voltage DC power straight from the grid. Bypassing the car’s own (typically much smaller) onboard charger entirely, this converted DC power is then sent directly to the battery pack. A very high level of technical sophistication is required for this direct DC approach.Engineers must overcome significant challenges like managing intense heat generation at high power levels (often requiring sophisticated liquid cooling systems), handling fluctuations in grid demand, and ensuring compatibility with diverse vehicle battery systems operating at different voltages and accepting varying currents. Key components like high-power IGBT (Insulated-Gate Bipolar Transistor) semiconductors and complex intelligent control algorithms are critical and demand rigorous engineering. This allows superchargers to operate across a wide voltage range (commonly 200V to over 1000V) and push currents of 300A to 600A or even higher. The result is charging power that easily surpasses 100kW. Mainstream superchargers now operate between 180kW and 480kW, with cutting-edge systems from manufacturers like Tesla (V4) and XPeng (S4) exceeding a staggering 600kW.

II. Charging Speed & Suitable Scenarios

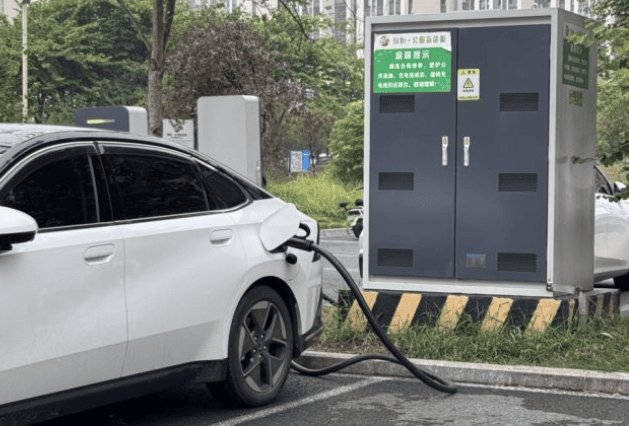

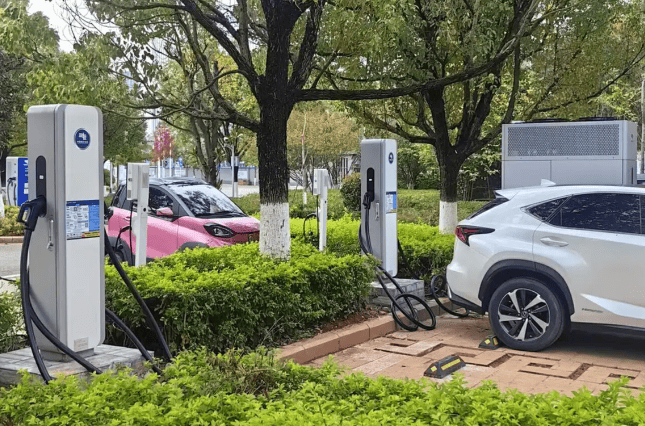

The difference in charging speed is nothing short of dramatic. Standard EV chargers operate at a pace suited for longer dwell times. Consider a typical 7kW home charger attempting to replenish a 60kWh battery pack – theoretically, this would take roughly 60kWh divided by 7kW, equating to about 8.5 hours for a full charge. Even public “fast” AC chargers, often rated at 60kW to 120kW (though still AC, relying on the OBC), usually require 30 to 60 minutes just to reach an 80% state of charge for a typical EV battery. This speed defines their primary application scenarios. They are the backbone of home charging, where vehicles park for extended periods overnight, perfectly leveraging off-peak electricity rates (often as low as $0.04-$0.07 per kWh) for cost-effective replenishment. This slow, steady charging is also generally considered gentler on the battery, promoting better cell balancing over time. Public slow charging zones are common sights in shopping malls, office buildings, and residential complexes, catering to the “park and charge” concept where users might be stationary for 1-3 hours while working, shopping, or dining. Their lower operational costs (public AC charging typically around $0.14-$0.21 per kWh) also make them ideal for users who prioritize cost savings over rapid charging.

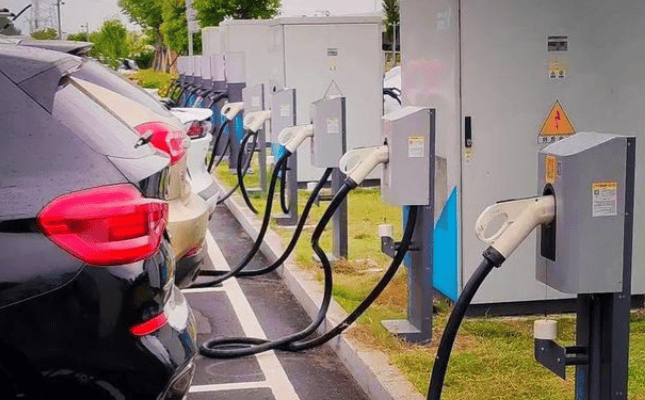

Superchargers, however, deliver an experience closer to refueling a gasoline car. Using the same 60kWh battery example, a powerful 480kW supercharger could theoretically add approximately 30kWh (taking the battery from 30% to 80%) in a mere 30kWh divided by 480kW, equating to about 3.75 minutes. While real-world factors like battery protection systems that deliberately slow down charging (tapering) as the battery fills up mean actual times are longer, it’s common to add 300+ kilometers (186+ miles) of range in just 5 to 10 minutes. This blistering speed dictates their strategic placement. They are essential for highway travel, densely deployed along major routes and in key urban hubs or dedicated brand charging stations. Their purpose is clear: solve “range anxiety” during long journeys by enabling rapid mid-trip top-ups, or provide a quick solution when a driver needs significant range added in a very short time due to unexpected needs or poor planning. Users typically spend no more than 15-20 minutes at these stations, making them indispensable for business travel, inter-city commuting, and any situation where time efficiency is paramount. While supercharging carries a cost premium, the time saved is often invaluable for these users. Standard chargers and superchargers are not rivals; they are complementary technologies serving fundamentally different needs within the EV ecosystem.

III. Installation Requirements & Costs

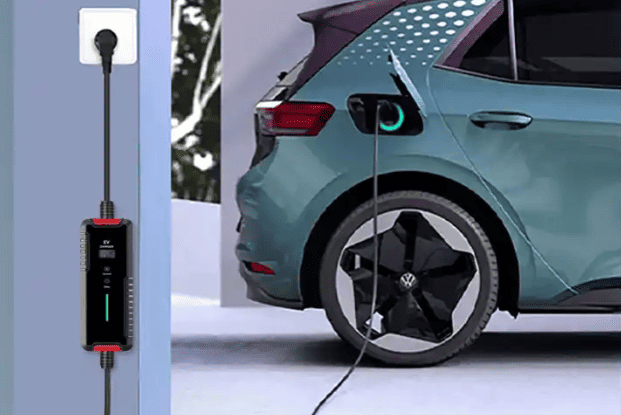

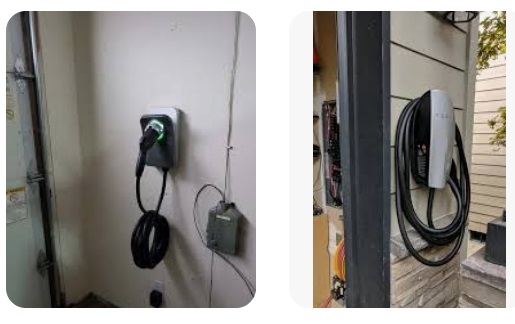

The infrastructure demands and associated costs for these two charger types create a clear divide between consumer and commercial applications. Standard EV chargers, particularly the ubiquitous 3.5kW to 7kW AC units designed for home use, boast relatively simple installation. For a typical 7kW charger, installation usually involves connecting to a standard 220V/240V home electrical panel, provided the panel has sufficient spare capacity (often requiring a minimum 30-40 Amp circuit breaker). Wiring requirements are manageable, typically needing 6 AWG (American Wire Gauge) copper conductors. Many residential installations are straightforward enough that homeowners can sometimes perform them after obtaining necessary permits and approval from their property management or utility. Public AC chargers or moderate DC fast chargers (around 60kW-120kW) require a step up, needing a 380V/400V three-phase power supply and coordination with the local utility regarding grid capacity availability at the installation site. They also need adequate space for ventilation and cooling, but their overall demands on the electrical grid infrastructure are substantially lower than those of superchargers.

Supercharger installation, however, presents formidable challenges. The sheer power draw is immense. Consider a station with four 480kW supercharger cabinets – if all operate simultaneously, the peak demand can reach 1920kW (1.92 Megawatts). This necessitates a dedicated, high-capacity electrical transformer, typically rated at 2000kVA or higher. Crucially, the installation site must be near an existing high-capacity electrical substation or have provisions for significant and expensive grid upgrades; otherwise, the station’s power output may be severely throttled due to insufficient local grid capacity. Beyond the electrical demands, the physical site requirements are stringent. Liquid cooling systems for the charging cables and dispensers are often essential to manage heat, requiring complex plumbing. High-voltage cabling (like 10kV feeder lines) is standard. Furthermore, the ground must support substantial weight, and fire safety standards are significantly elevated due to the vastly higher energy levels involved, making installations in dense urban cores particularly difficult and expensive.

This complexity translates directly into a massive cost disparity. Standard EV chargers are relatively affordable. A quality home AC charger unit, including installation, typically ranges from $1,000 to $3,000 USD. Public DC fast chargers in the 60kW-120kW range cost approximately $20,000 to $50,000 per unit. Superchargers, however, are in a different financial league. The unit cost for a single high-power supercharger cabinet can easily reach $100,000 to $300,000, driven primarily by the expensive liquid cooling systems, massive power conversion modules, and sophisticated control electronics. When factoring in the substantial costs for site preparation, high-voltage grid connections, potential substation upgrades, and installation labor, the total cost for a station with just 4 supercharger stalls can easily exceed $1 million USD. This makes supercharger stations an investment order of magnitude greater (10-20 times more) than deploying standard public fast chargers.

IV. Impact on Battery Health & Compatibility

How you charge your EV can influence the long-term health of its most expensive component: the battery pack. Standard EV chargers, particularly slower AC charging, are generally considered the gentler option. The lower current involved allows the electrochemical reactions within the battery cells to proceed more gradually. This slower pace helps minimize the growth of detrimental lithium dendrites (needle-like structures that can cause internal shorts) and reduces overall stress and heat generation. Consequently, frequent use of slow charging is widely recommended by most automakers as the preferred method for daily use to maximize the battery’s overall lifespan and maintain its capacity over many years.

Supercharging, with its extremely high currents, naturally generates significantly more heat within the battery cells very rapidly. While modern Battery Management Systems (BMS) are highly sophisticated – actively cooling the battery pack and dynamically reducing the charging current (tapering) as the state of charge increases to mitigate risks – the fundamental physical stress of repeated high-power charging can potentially accelerate long-term capacity degradation compared to exclusive slow charging. This effect can be more pronounced in very cold ambient temperatures or as the battery ages. However, it’s crucial to note that significant advancements in battery technology (like silicon-based anodes, improved thermal management, and structural packs like CTP/CTC) combined with smarter BMS algorithms have substantially reduced this impact. Major manufacturers now design their vehicles and warranties (e.g., 8 years/100,000-150,000 miles with guaranteed minimum battery health, like 70% retention) with the expectation of regular supercharger use, keeping degradation within acceptable limits for most consumers.

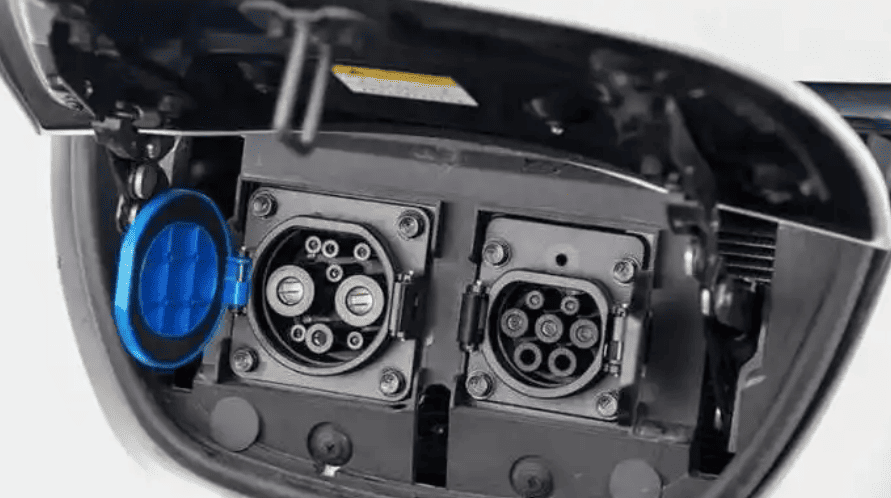

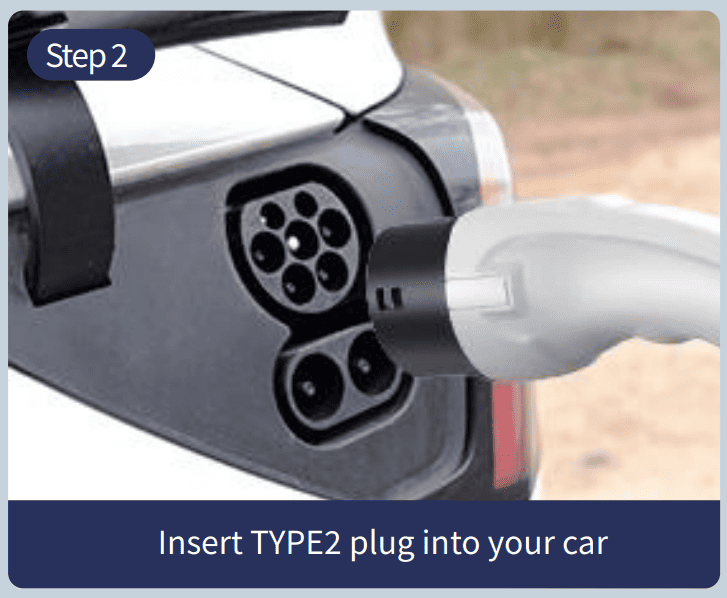

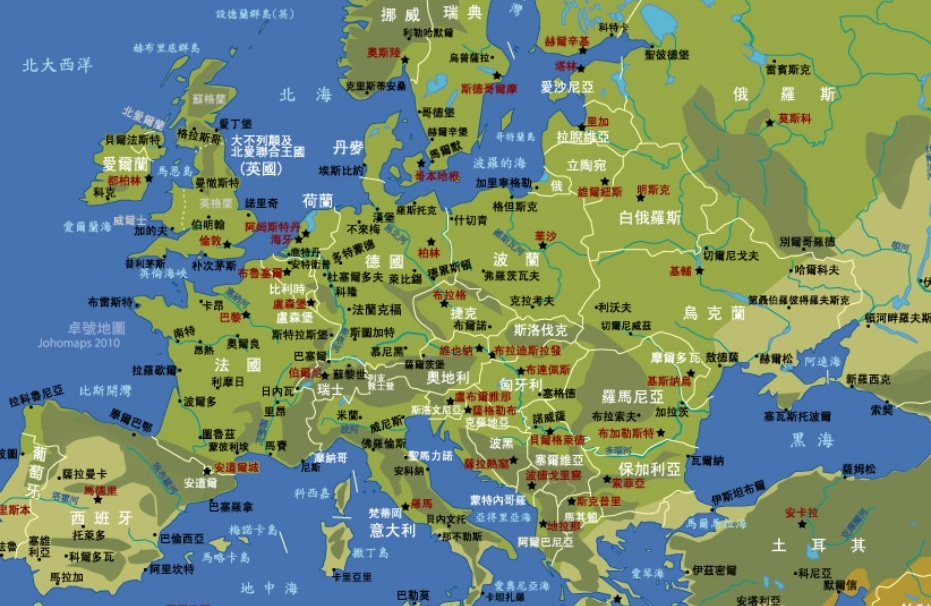

Compatibility also differs markedly. Standard AC chargers offer near-universal compatibility. Any electric vehicle equipped with the appropriate physical connector (like the CCS Combo 1 in North America or Type 2 Mennekes in Europe) can utilize a public AC charger. The actual charging speed is simply capped by the vehicle’s own onboard charger’s maximum power rating; the charger itself merely supplies the AC power. Superchargers, however, face greater compatibility hurdles. Achieving the maximum advertised power (like 250kW or 350kW+) requires a perfect match between the charger’s capabilities and the vehicle’s electrical architecture. A vehicle built on an 800V battery platform can take full advantage of a high-power 800V supercharger. However, a more common 400V platform vehicle using the same charger will be limited to significantly lower power (perhaps 150kW or less) because the charger must adapt its output to the lower battery voltage. Furthermore, while many supercharger networks are opening up (like Tesla’s to non-Tesla vehicles via adapters in many regions), using an adapter or connecting to a network primarily designed for a different brand can sometimes result in further reduced charging speeds compared to using a native charger.

V. Cost to Use & Future Evolution

The speed premium and infrastructure investment are reflected in the cost per kWh for charging. The most cost-effective charging is provided by standard EV chargers, particularly those found in homes. The cost per kWh is usually very low ($0.05–$0.08/kWh during off-peak hours), leveraging residential electricity rates. The typical range for even public AC charging is $0.14 to $0.21/kWh. This results in a very low cost of driving, frequently between $0.05 and $0.15 per mile. Even though they are still less expensive than gas, superchargers are much more expensive. Rates, which normally range from $0.28 to $0.42 per kWh and can rise above $0.56/kWh during periods of peak demand, combine electricity costs and network service fees. This results in a per-mile cost of roughly $0.20 to $0.40 for many EVs, which, while substantially lower than the $0.50-$0.80 per mile cost of a comparable gasoline car, is noticeably higher than the cost of slow charging at home. Users pay for the unparalleled convenience and speed.

Looking ahead, both technologies are evolving towards greater integration and capability. Smarter and more integrated into the larger energy ecosystem are standard EV chargers. Advanced features like vehicle-to-grid (V2G) technology, integration with home solar panels and battery storage systems (enabling daytime solar charging for evening/nighttime use), and remote control via smartphone apps will be increasingly featured in future home and public AC chargers. With V2G, EVs can function as mobile energy storage devices, resupplying the grid with electricity during periods of high demand to help stabilize it and possibly generate revenue for the owner of the vehicle. As a result of this development, standard chargers will be essential components of smart, distributed energy networks in the future. With industry targets aiming for 1000kW (1 Megawatt) and beyond, superchargers are pushing the limits of power delivery.Simultaneously, efforts are focused on making deployment more feasible and cost-effective. Technologies like dynamic “power sharing” – where multiple charging stalls at a station intelligently distribute available grid power based on demand and vehicle connection status – help manage grid constraints without needing constant massive infrastructure upgrades. Networks of liquid-cooled superchargers are becoming standard for major automakers (XPeng, Li Auto, NIO, Tesla). Furthermore, supercharging is increasingly seen as part of a diversified rapid energy replenishment strategy, complementing other technologies like battery swapping stations (offering a literal 5-minute “battery change”) and exploring future possibilities like high-power wireless charging, collectively building a robust “ultra-fast charging + swapping” network.

Conclusion: Distinct Roles, Essential Synergy

The story is one of vital synergy rather than rivalry. The essential “daily fueling stations” for electric vehicles are standard EV chargers. The basic need for convenient, reasonably priced charging where cars spend the majority of their time parked—at home, at work, or at local locations—is perfectly addressed by their advantages, which include low cost, low battery stress, and simplicity of installation. They offer the consistent, dependable energy replenishment that is the cornerstone of EV ownership. On the other hand, superchargers serve as the potent “emergency accelerators.” The crucial obstacle of “range anxiety,” especially for long-distance travel, is directly addressed by their ground-breaking high power and speed. They offer a vital safety net for unforeseen high-mileage requirements and make electric vehicles a competitive alternative to gasoline-powered cars on road trips. One cannot effectively replace the other; they are the complementary “twin engines” powering the mass adoption of electric mobility. Looking forward, advancements in battery chemistry (like solid-state batteries promising faster inherent charging and longer life) and grid modernization (including smart microgrids and enhanced renewable integration) will gradually reduce the cost and complexity of deploying supercharger networks. Simultaneously, standard chargers will evolve beyond simple power delivery points into intelligent “energy interaction terminals,” actively participating in grid management and enabling new consumer services. Together, these evolving technologies will drive the maturation of a seamless, efficient, and user-friendly electric vehicle ecosystem.