EV Charger Gun

AC TYPE2 16A 3.5KW Display Screen Portable Ev Charger EU Standard

Specification of EV Charger Gun

Parameters of EV Charger Gun:

Functional design

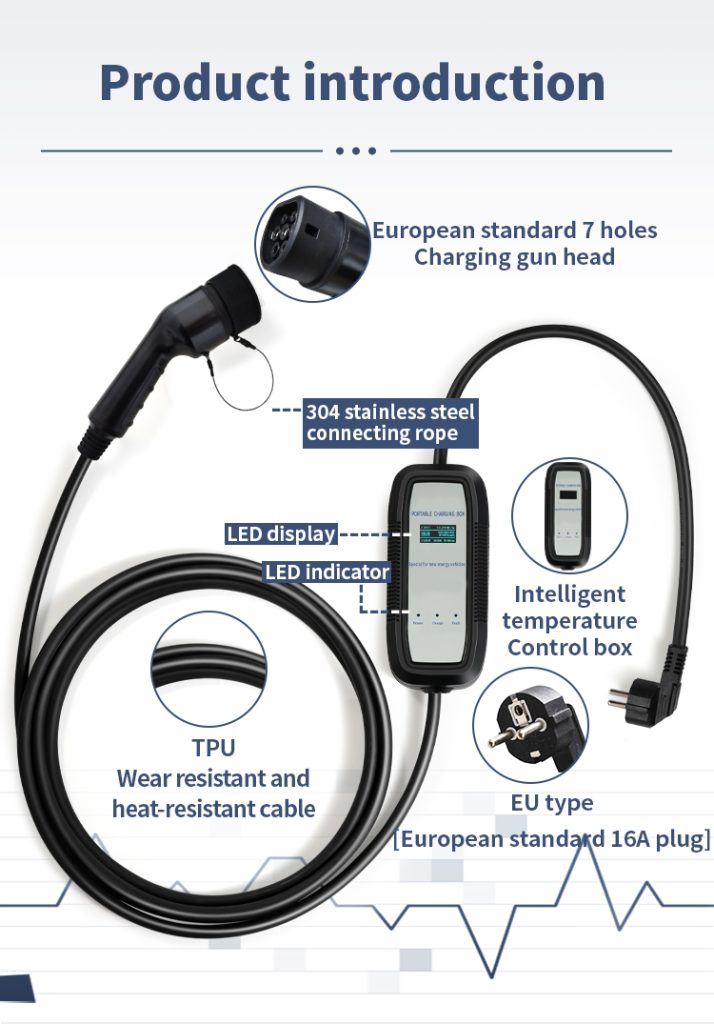

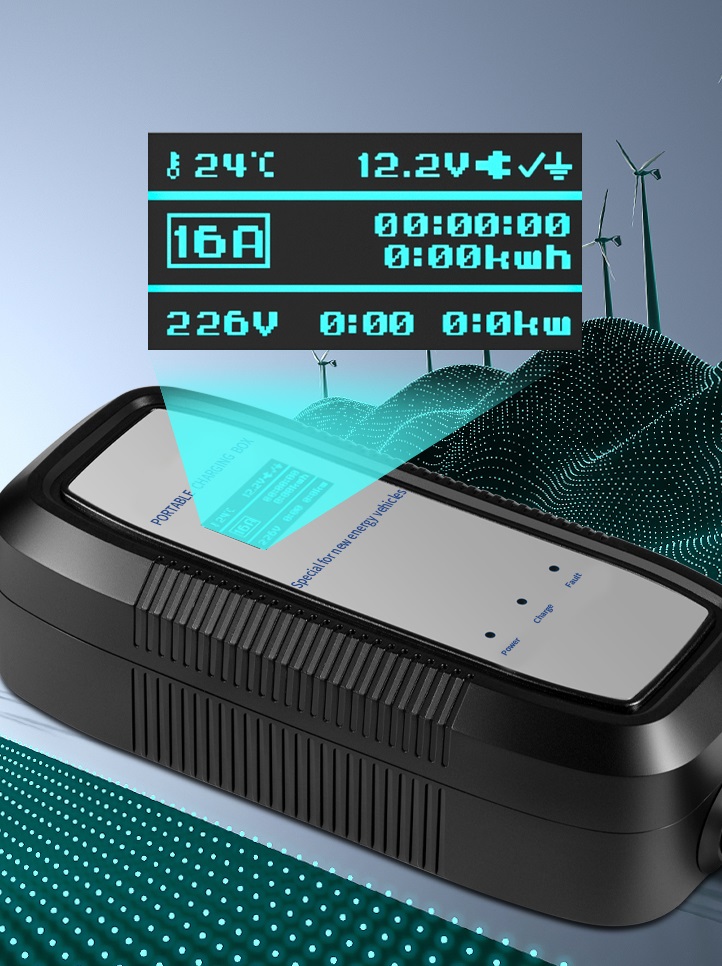

| Interface | Display Screen、LED Indicator Light |

| Communication | / |

Safety design

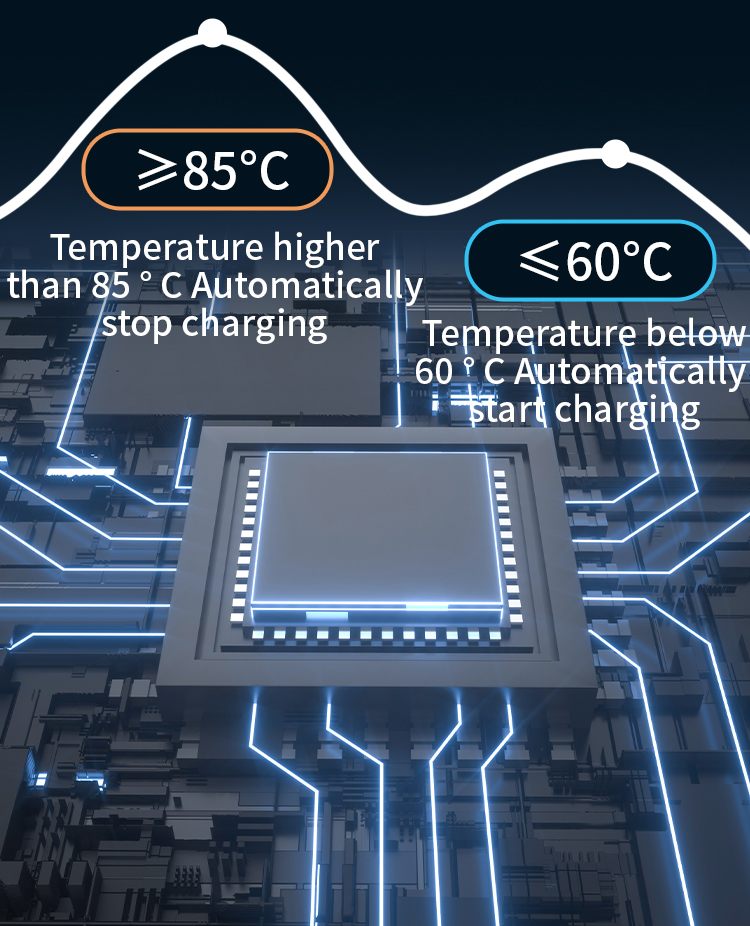

Over Curren Protection、Residual Current Protection、Ground Protection、Surge Protection、Over/Under Voltage,Frequency,Temperature Protection

Packaging specification

LWH:410410125mm【2.8KG】

Environment index

| Applicable scene | Indoor or Outdoor |

| Work Humidity | 5%~95%(non-condensing) |

| Work Temperature | -30℃~+50℃ |

| Work Altitude | <2000M |

| Protection Class | Charging Gun IP67/Control Box IP54 |

| Cooling Method | Natural Cooling |

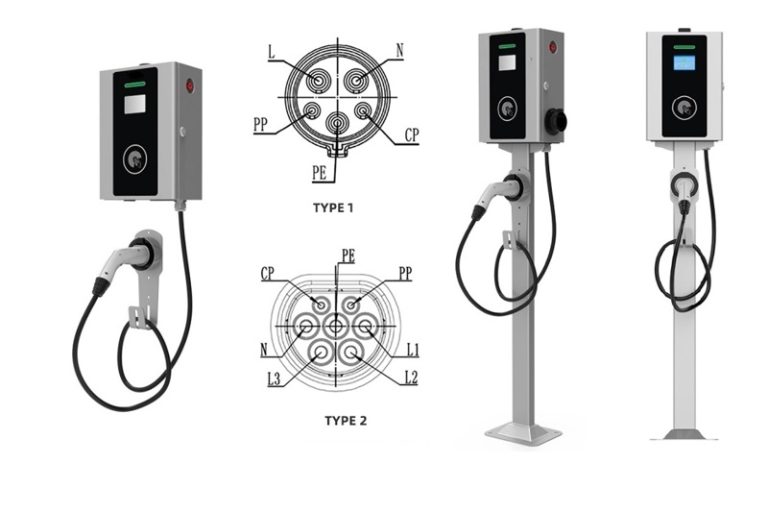

| Standard | IEC 62196-2 |

| Flammability rating | UL94 V0 |

| Certificate | CE、RoHS |

Electrical index

| Input Voltage | AC90V-265V |

| Input Frequency | 50Hz/60Hz |

| Max Power | 3.5KW |

| Output Voltage | AC90V-265V |

| Output Current | 16A |

| Standby Power | 3W |

Appearance structure:

| Name | AC 16A Screen Ev Charger |

| Model | Plug&Play |

| Enclosure | Charging gun-Control boxPC9330 |

| Size | Charging Gun 240*98*70mm/Control Box 220*98*48mm【H*W*D】 |

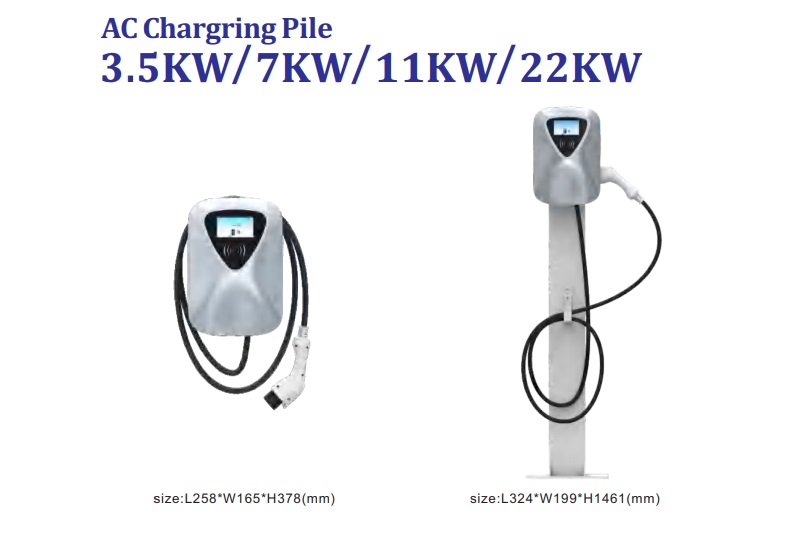

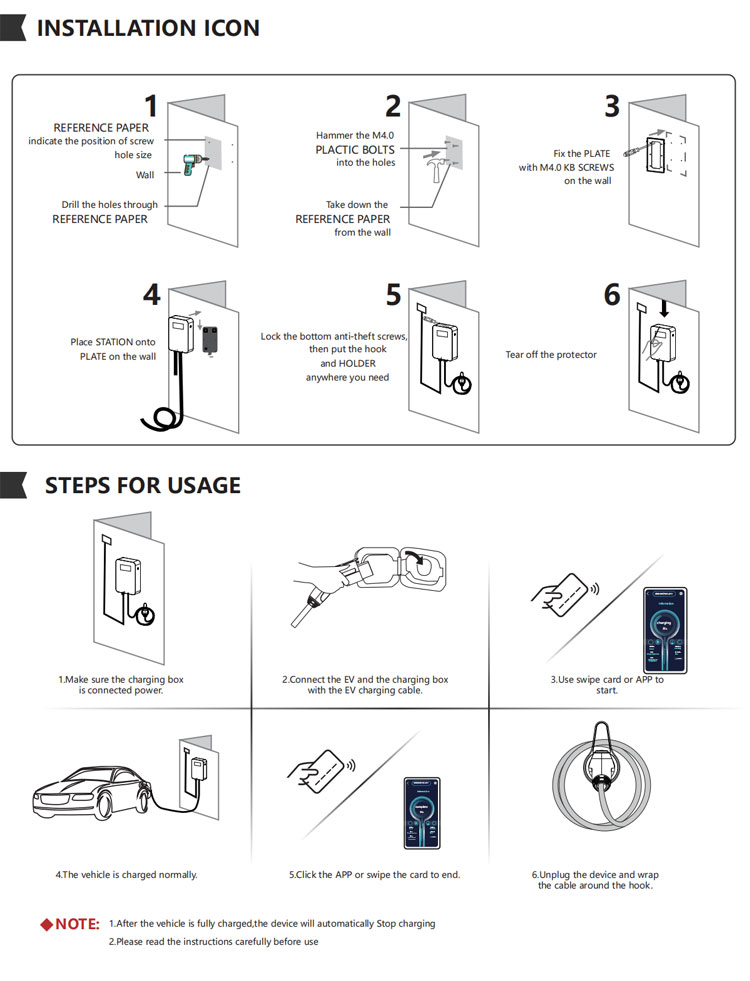

| Installation Method | Floor-mounted/Wall-Mounted |

| Install Components | Screw |

| Power Direction | Input(Up) & Output(Down) |

| Net Weight | About 2KG |

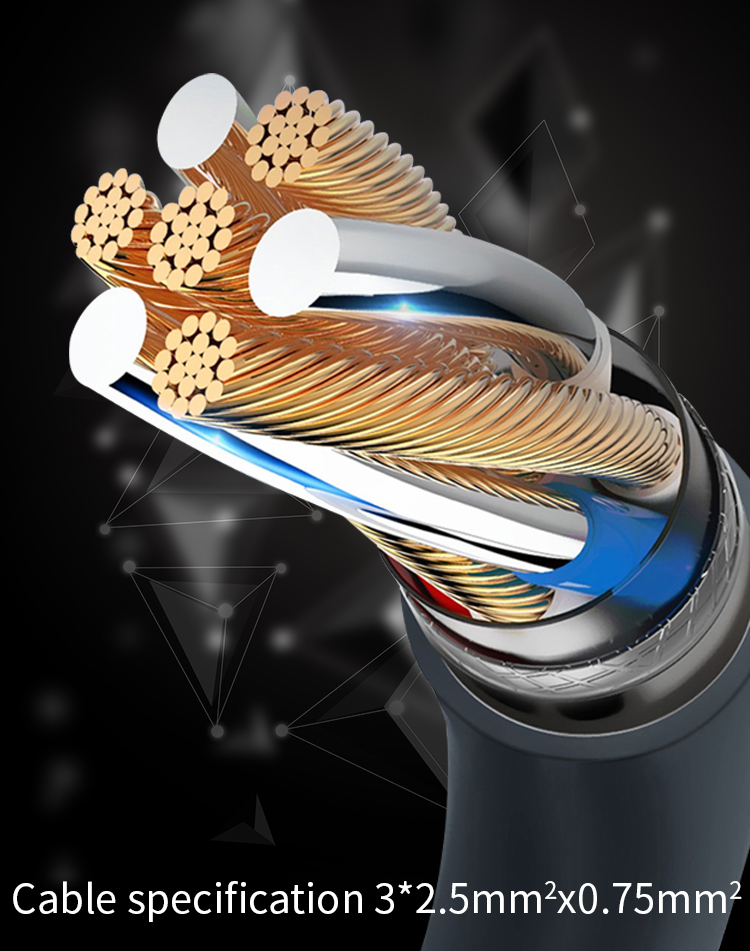

| Cable Size | 3*2.5mm²+0.75mm² |

| Cable Length | 5M or Negotiation |

Introduction of EV Charger Gun:

Discover an Extensive Range of Wholesale EV Charger Gun on ChargersGO!

Are you on the lookout for an expansive collection of wholesale EV Charger Gun at incredible prices? Look no further than ChargersGO, where you’ll find one of the largest selections available. Our EV Charger Gun are designed to cater to various types of trucks and rides, ensuring compatibility across a wide range of vehicles.

The Importance of Chargers: Keeping You Powered On the Go

A charger isn’t just an accessory; it’s a vital component for your car, truck, or SUV. Its primary purpose is to ensure that your devices, like phones, remain charged throughout your journey. While modern car chargers are notably more durable, they can eventually wear out after years of use or extensive mileage.

The EV charging guns featured on our list aim to make your travels more enjoyable while ensuring their longevity. Our products boast state-of-the-art technology, making them resistant to diverse external factors such as varying weather conditions, geographic locations, and vehicle types. Whether you’re navigating icy mountains or scorching deserts, you’ll find the perfect solution here.

Global Reach and Unbeatable Discounts

Our network of EV Charger Gun merchants spans the globe, enabling suppliers worldwide to connect with them. Simply choose from the list of merchants and select your preferred shipping options. Don’t forget to explore our tempting discounts, ensuring you get the best value for your investment.

ChargersGO: Empowering a Greener Future

ChargersGO is an emerging energy company established on the foundation of the renowned Onitl cable factory. Leveraging top-quality wires, cables, and advanced new energy equipment production technology, we specialize in crafting charging connectors for electric vehicles, EV charging cables, mode 2 portable chargers, and wall-mounted charging stations.

Our annual output of 50,000 sets of charging guns adheres to EN/IEC and SAE standards, backed by a wealth of experience in exporting to the European and American markets.

A Diverse Range of EV Charger Gun to Suit Your Needs

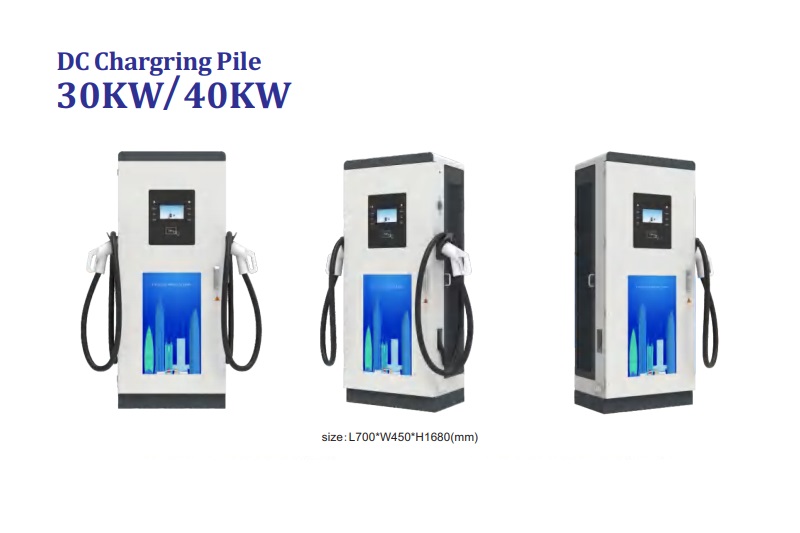

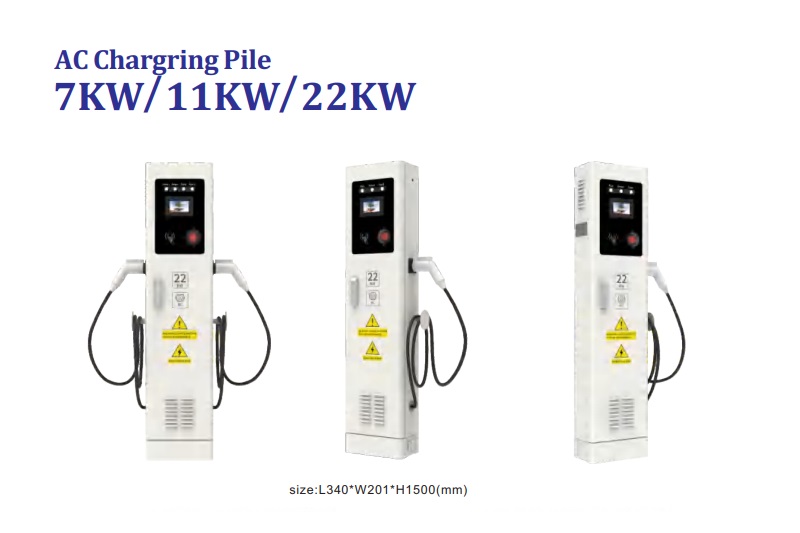

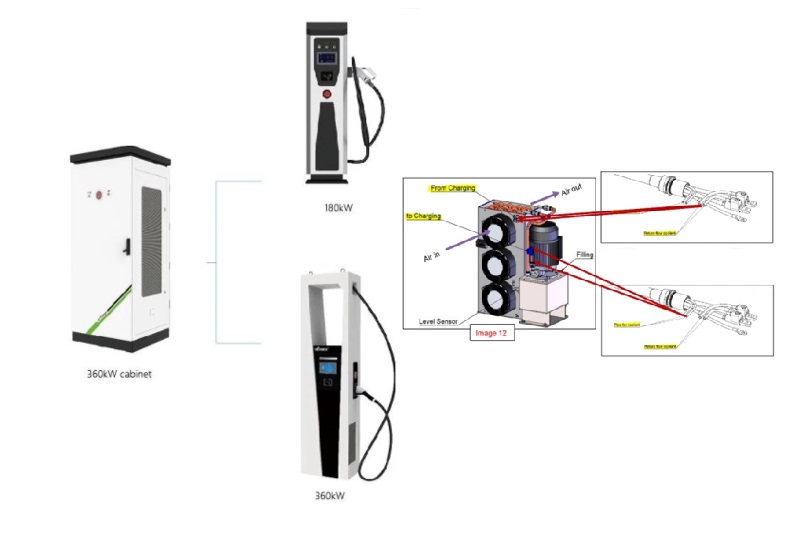

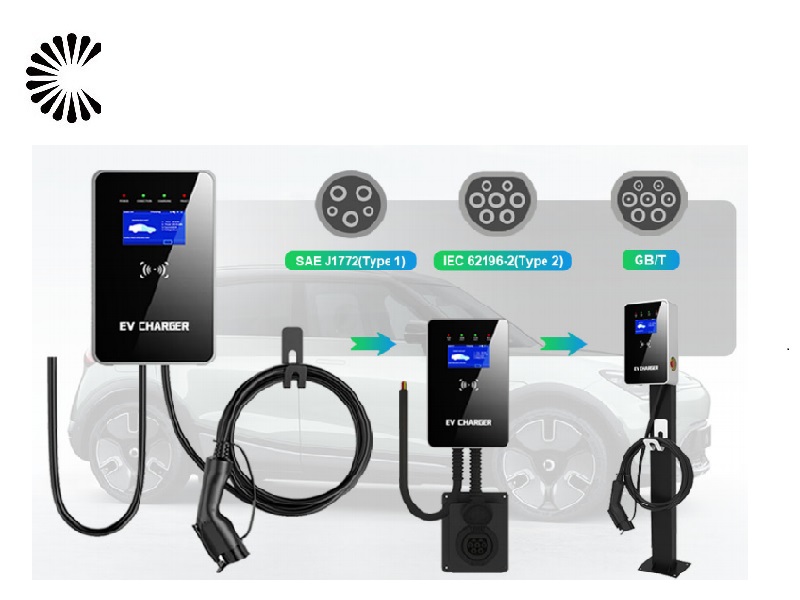

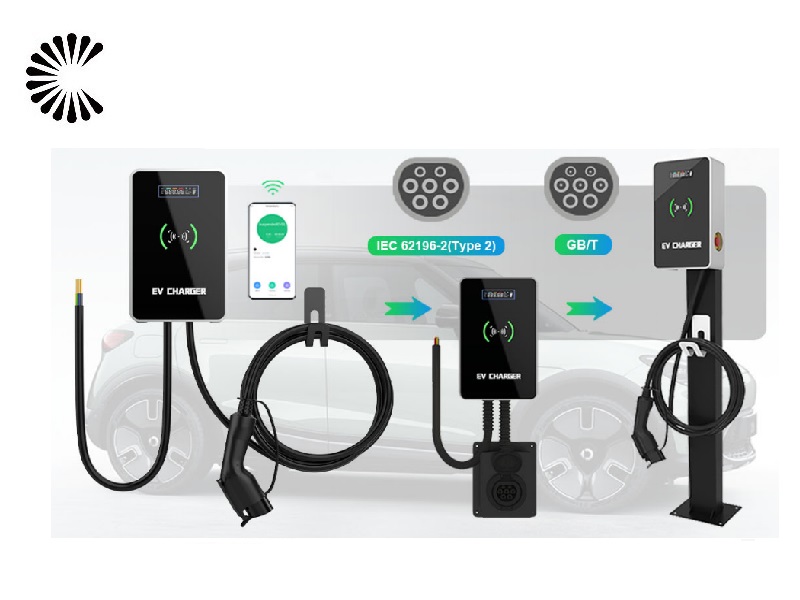

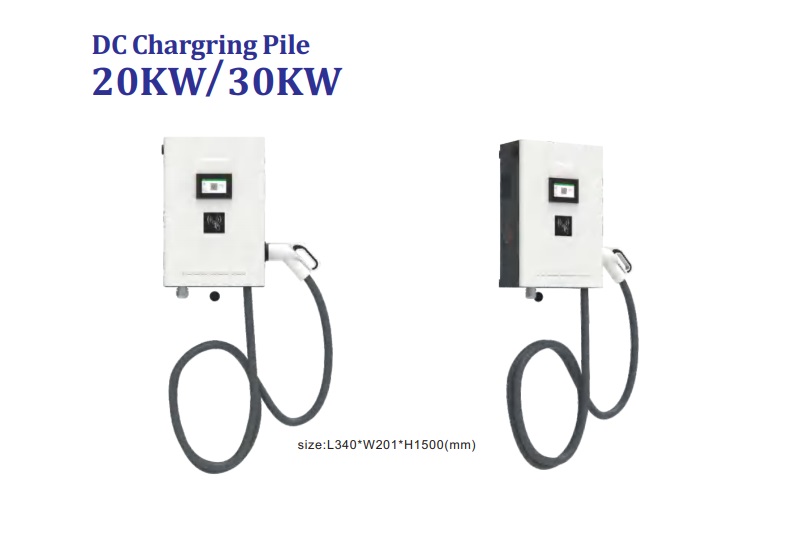

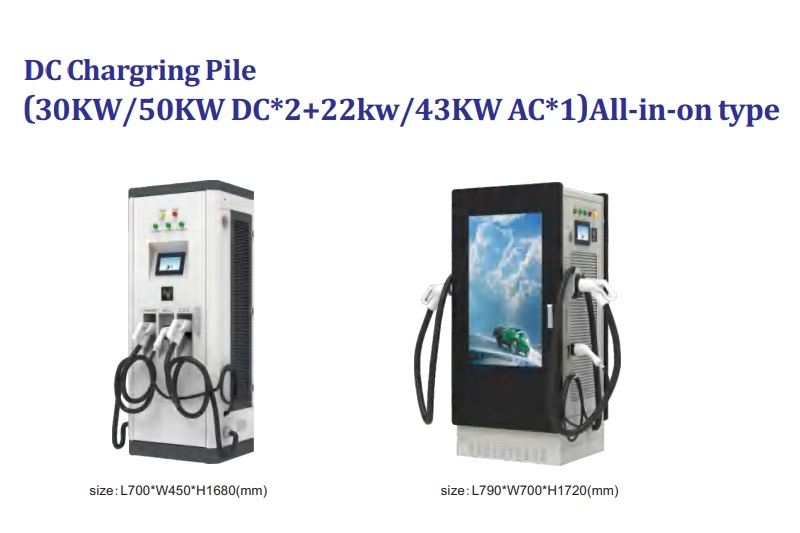

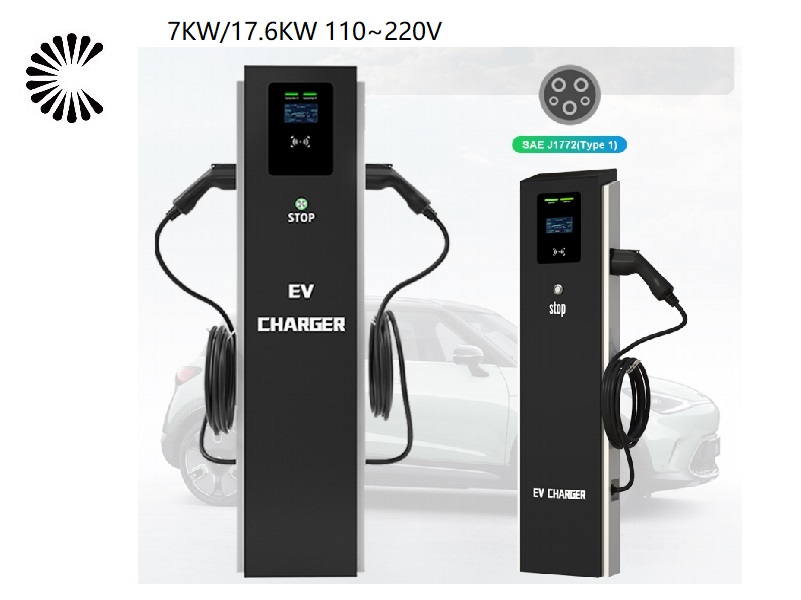

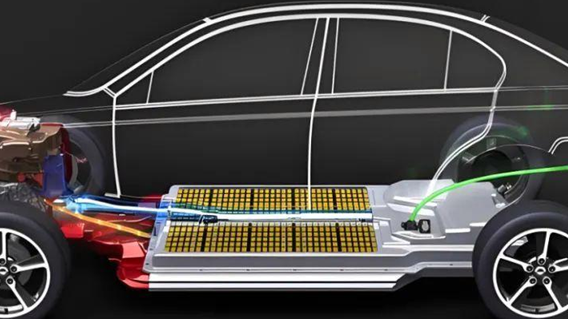

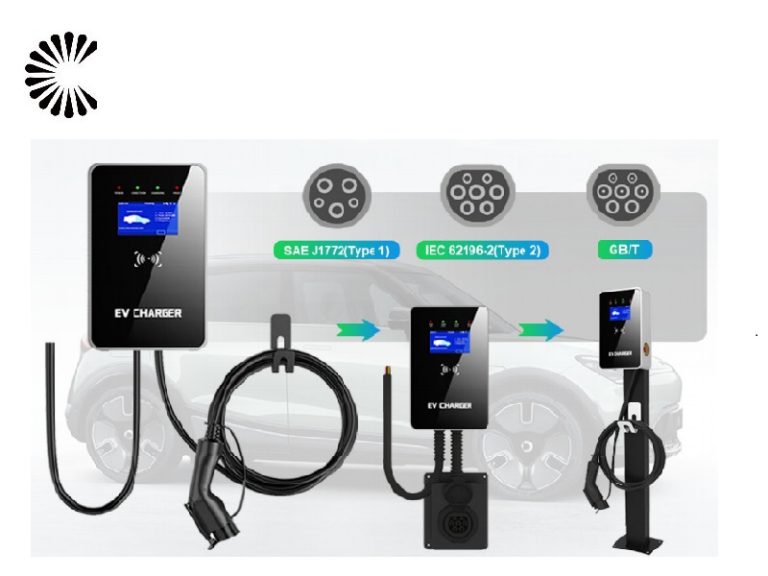

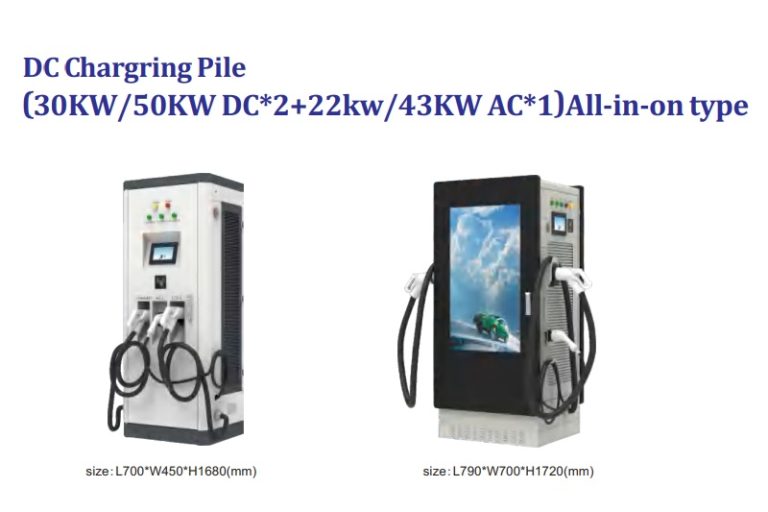

Our EV charger offerings cater to all electric vehicles, boasting both wall-mounted and floor-mounted designs. With IP65 dust and waterproof housing, they’re ideal for both indoor and outdoor usage. The AC EV Charger Gun’s output ranges from 16 to 32 amps, while the DC fast EV Charger Gun can deliver an impressive 262 kW.

Experience Excellence with BENY

With over 30 years of expertise in EV Charger Gun and PV products, BENY ensures our chargers exceed expectations in performance and service life. Our robust construction empowers you to achieve your business objectives while promoting your brand. Reach out to us for a complimentary consultation.

Wide Compatibility with Global Electric Vehicles

ChargersGO AC EV Charger Gun is compatible with a wide range of global electric vehicle models, including renowned names like Audi, BMW, Mercedes, Porsche, Volkswagen, Volvo, Tesla, Chevrolet, Nissan, and more.

For a Greener Tomorrow, Choose ChargersGO

With hot tags like dual-gun integrated EV Charger Gun, DC home chargers, type 2 EV home chargers, and more, ChargersGO offers a comprehensive range of products. Join us in paving the way for a sustainable future while benefiting from quality, innovation, and performance.

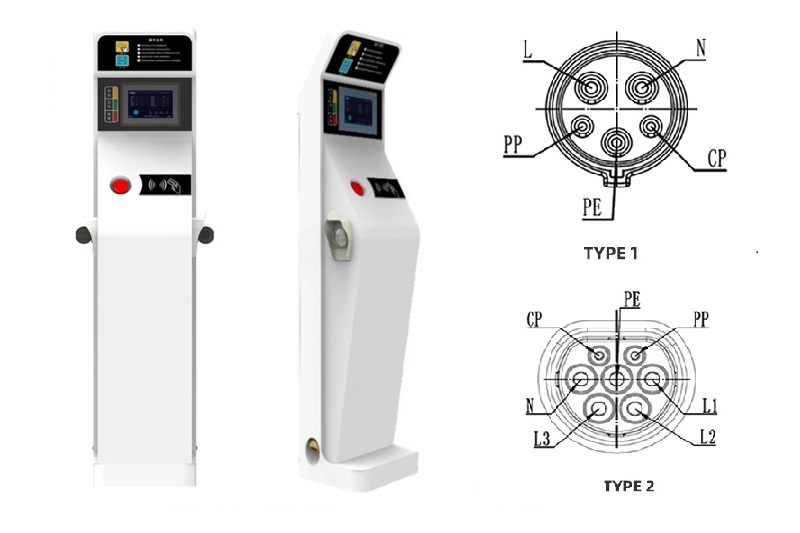

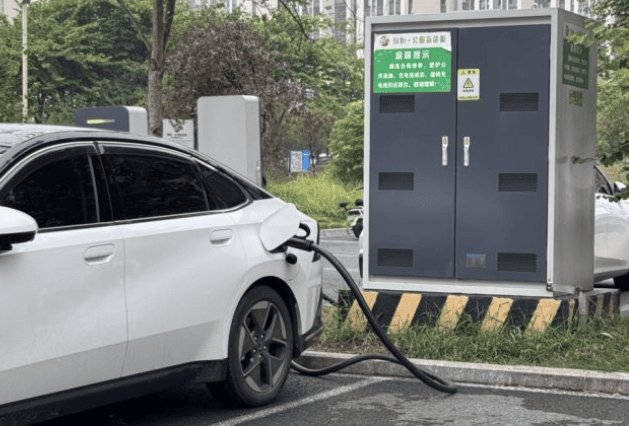

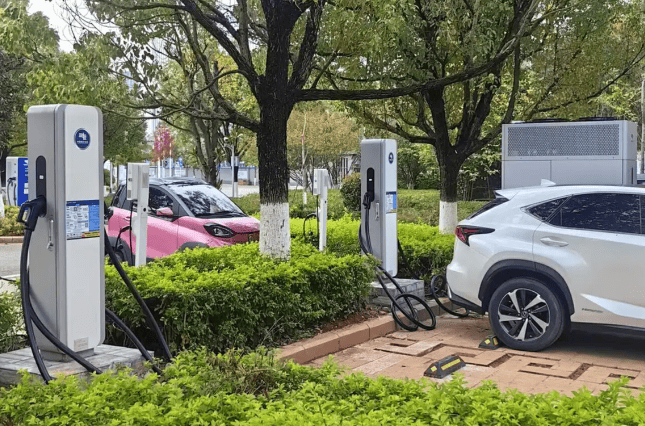

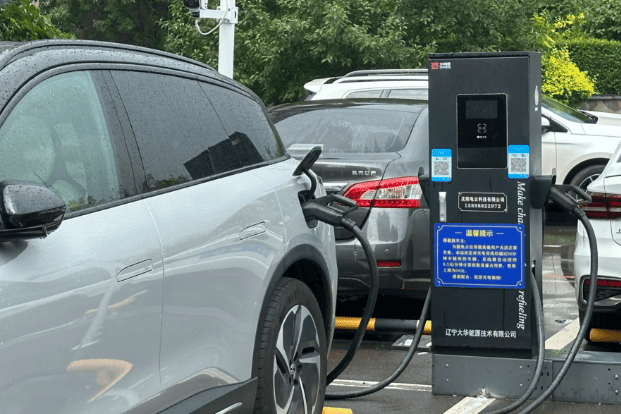

Pictures of EV Charger Gun:

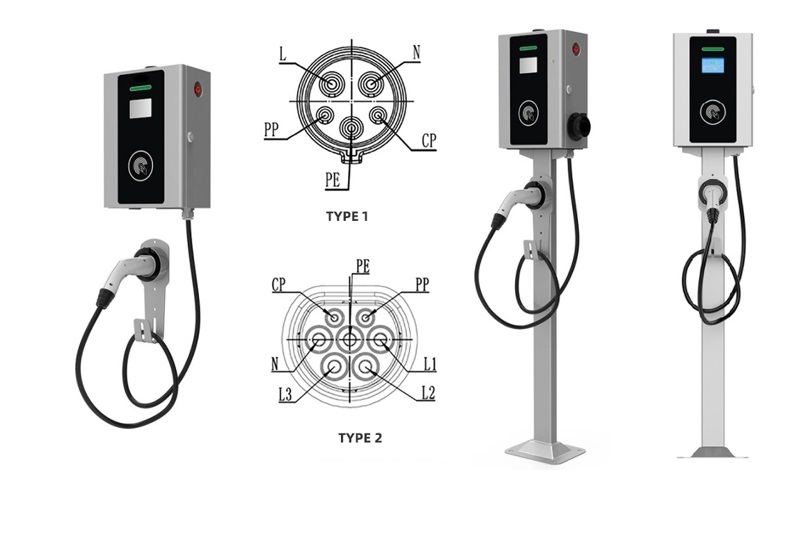

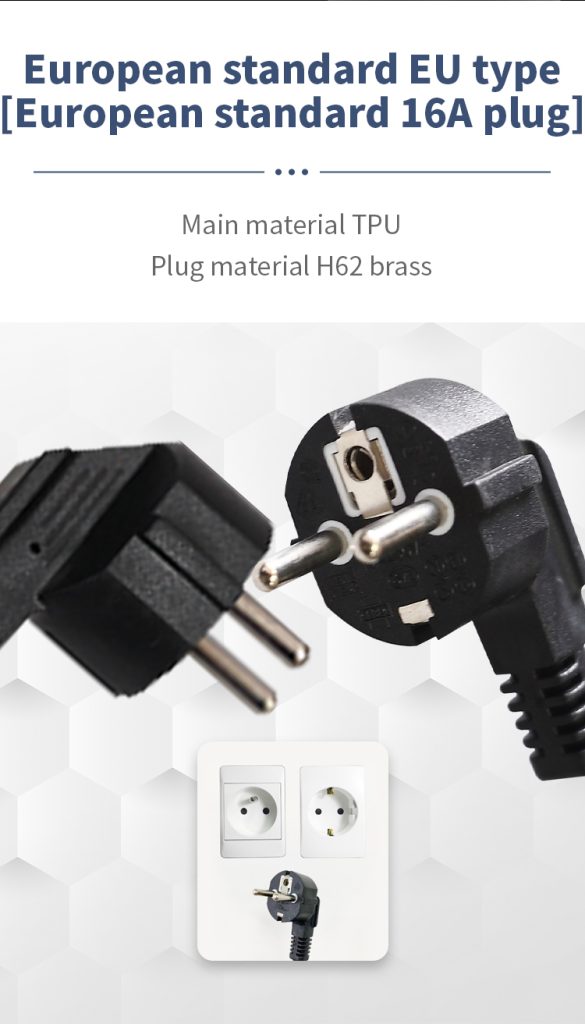

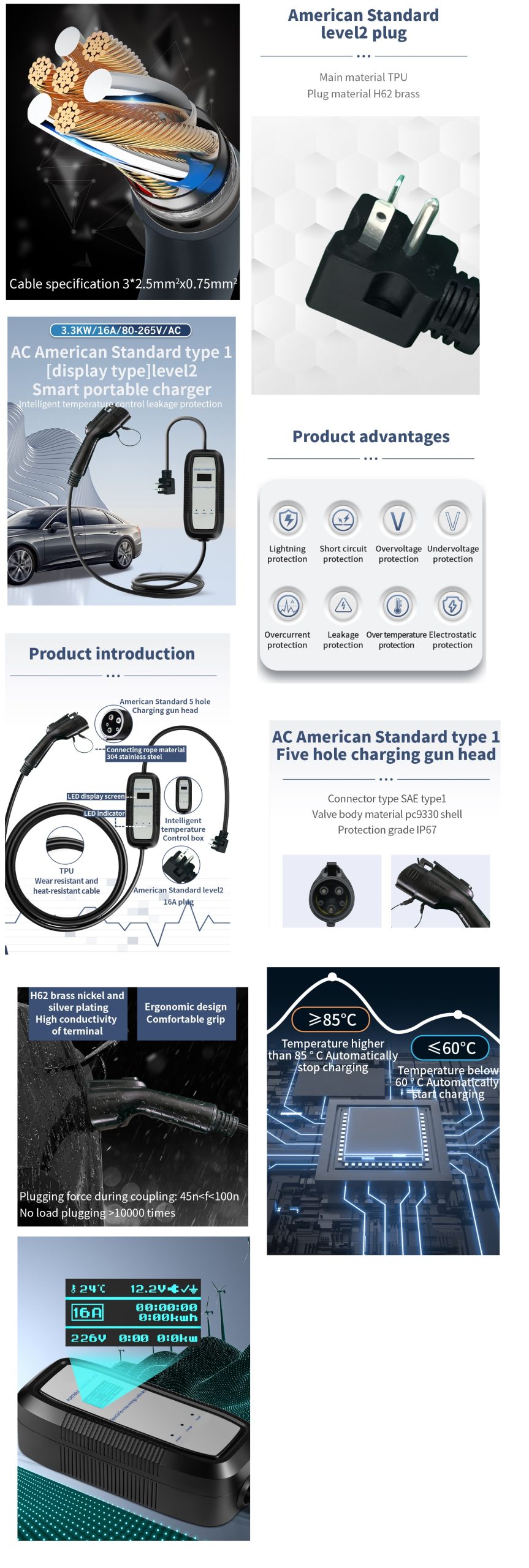

European Standard Level 1:

American Standard Level 2:

Advantages of EV Charger Gun:

Small size, easy to storage, cost-effective, charging statuas identification;

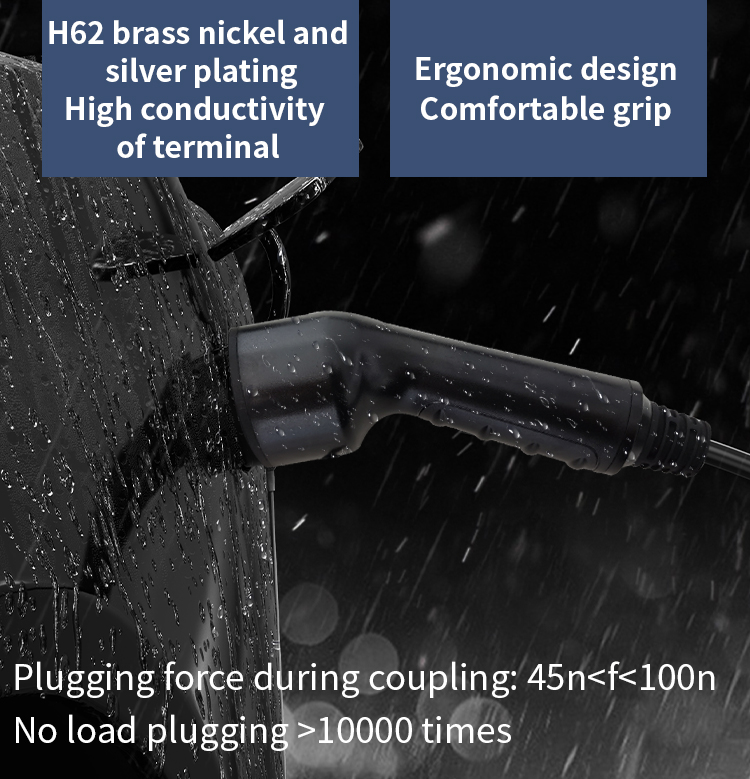

IP67 Level: Injection-molded one-piece gun, have anti-corrosion and weather proof;

Protection: Leakage current protection, and over temperature protection etc;

External pressure resistance waterproof and dustproof clear display;

Shell material,protection grade IP54, Display mode LED display LED indicator;

European standard7-hole charging gun head, Connector type European Standard IEC type 2;

High quality cable cold, heat resistance, TPU,the external material of the cable is more wear-resistant and does not deform Cable core material oxygen free pure copper cable to reduce charging loss Waterproof and flame retardant, not easy to heat, more stable charging.

Why Choose Us?

Our EV Charger Factory Introduction

| Business Type: | Manufacturer/Factory | Main Products: | EV Charger |

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

ChargersGO Factory is a professional manufacturer for EV Charger. Our main product including slow charger, fast charger, DC EV Charger, AC EV Charger, commercial EV Charger, charger for home, EV charger level 1, level 2 and level 3 etc. All products in accordance with the China GMP design requirements. And also we have other certifications.

Business Philosophy

“Quality is the main policy of sales” and “integrity is the principle of success” are the business philosophy of our people. We carry out one-year warranty, lifelong maintenance service, with technical consultation and other services, and long-term supply of equipment. Welcome new and old customers to negotiate cooperation!

Production Process:

Producing an Electric Vehicle (EV) charger involves a series of carefully orchestrated steps to ensure the charger’s quality, safety, and performance. The production process typically consists of the following key stages:

- Design and Engineering: The process begins with the design and engineering phase. Skilled engineers and designers work together to create a blueprint for the EV charger. They consider factors like power capacity, safety features, charging protocols, and compatibility with various electric vehicle models.

- Component Sourcing: Once the design is finalized, the production team sources the necessary components and materials for the charger. These components can include circuit boards, connectors, casing materials, power modules, and safety components. Manufacturers often prioritize high-quality, reliable components to ensure the charger’s longevity and performance.

- Circuit Board Assembly: The core of an EV charger is its circuit board, which controls the charging process and ensures safe operation. Surface Mount Technology (SMT) machines precisely place electronic components onto the circuit board. Skilled technicians may also perform manual assembly for certain components that require extra care.

- Casing and Enclosure: The charger’s casing is an essential part of its design, providing protection from external elements and ensuring user safety. The casing is usually made of durable materials, such as aluminum or robust plastics. Injection molding or other manufacturing techniques are used to create the charger’s enclosure.

- Quality Control: Throughout the production process, rigorous quality control checks are conducted to identify any defects or inconsistencies. Each charger is tested at various stages to ensure its functionality and safety compliance. Quality control specialists meticulously examine the assembled units to meet industry standards.

- Safety Testing and Certifications: Before releasing the chargers to the market, they undergo rigorous safety testing and certifications. These tests may include electrical safety tests, thermal tests, and environmental tests to ensure the charger can operate reliably in different conditions.

- Final Assembly and Packaging: After successfully passing all tests and certifications, the chargers undergo final assembly and packaging. They are carefully packaged and prepared for distribution, along with user manuals and any necessary accessories.

- Distribution and Installation: The chargers are then distributed to retailers, charging network operators, or directly to end customers. Upon receiving the chargers, they are installed at charging stations or provided to electric vehicle owners for home charging.

- Customer Support and Maintenance: Once in use, manufacturers provide ongoing customer support and maintenance services to ensure the chargers continue to perform optimally. This includes troubleshooting assistance, firmware updates, and periodic inspections.

By following a well-structured production process and adhering to strict quality standards, manufacturers can produce high-quality EV chargers that contribute to the growth of electric mobility and a greener, sustainable future.

Certifications:

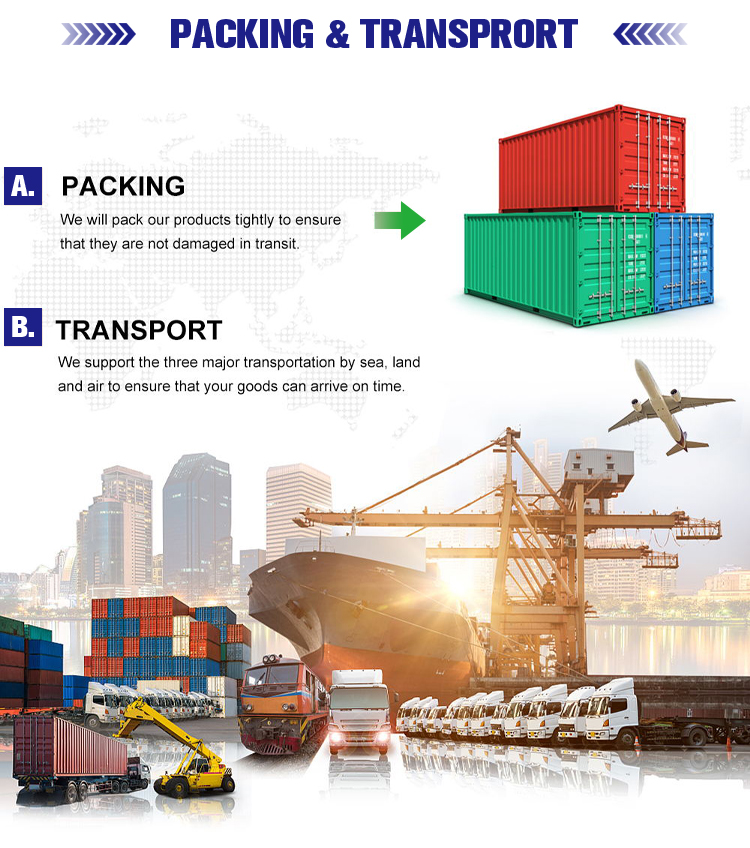

Small EV Charger Packing:

Retail Small EV Charger shipped with express.

Wsholesale Small EV Charger packed with export fumigation-free wooden cases, goes with bulk shipment or in container.

When packing small EV charger for sea shipment, it is important to take measures to ensure that the machines are protected from damage during transit. Here are some general steps that a manufacturer may follow when packing small EV charger for sea shipment:

- Clean and dry the charger: Before packing, the charger should be thoroughly cleaned and dried to prevent any moisture or debris from causing damage during transit.

- Disassemble the machine: If possible, the charger should be disassembled into its component parts to reduce its overall size and make it easier to pack.

- Wrap the charger in protective material: The charger should be wrapped in a layer of protective material, such as bubble wrap or foam, to protect it from scratches and impact during transit.

- Place the charger in a sturdy box: The wrapped charger should then be placed in a sturdy box that is appropriate for the size and weight of the machine. The box should be made of durable material, such as corrugated cardboard or plywood, and should be able to withstand the rigors of sea transit.

- Add packing material: The box should be filled with packing material, such as packing peanuts or air pillows, to provide cushioning and prevent the machine from shifting during transit.

- Seal the box: The box should be securely sealed with high-quality packing tape to prevent it from opening during transit.

- Label the box: The box should be clearly labeled with the charger’s name, weight, and any other relevant information, as well as the destination address and contact information.

Overall, the goal is to pack the small chargers in a way that will protect it from damage during transit and ensure that it arrives at its destination in good condition. It is important to follow proper packing procedures and use high-quality packing materials to minimize the risk of damage during sea shipment.

Large EV Charger Packing:

Packing a large EV charger for sea shipment can be a complex and challenging task. However, with careful planning and attention to detail, it is possible to pack a large machine for sea shipment in a way that will ensure that it arrives at its destination in good condition. Here are some general steps that a manufacturer may follow when packing up a large machine for sea shipment:

- Clean and prepare the machine: Before packing, the EV charger should be thoroughly cleaned and prepared. All fluids, such as oil or coolant, should be drained, and any loose or detachable parts should be removed.

- Disassemble the machine: If possible, the machine should be disassembled into its component parts to reduce its overall size and make it easier to pack. Each part should be carefully labeled and numbered to ensure that it can be easily reassembled at the destination.

- Protect delicate parts: Delicate or fragile parts should be wrapped in protective material, such as bubble wrap or foam, to protect them from damage during transit.

- Build a custom crate: A custom crate should be built around the machine to provide a secure and sturdy enclosure. The crate should be made of durable material, such as plywood, and should be designed to fit the machine snugly. The crate should also include braces or supports to prevent the machine from shifting during transit.

- Add cushioning material: The crate should be filled with cushioning material, such as packing peanuts or air pillows, to provide extra protection and prevent the machine from moving or shifting during transit.

- Securely fasten the machine: The EV charger should be securely fastened to the crate to prevent it from moving or shifting during transit. This may involve using straps, bolts, or other fasteners to hold the machine in place.

- Seal and label the crate: The crate should be securely sealed with high-quality packing tape, and should be clearly labeled with the machine’s name, weight, and any other relevant information. The destination address and contact information should also be clearly marked on the crate.

Overall, packing a large EV charger for sea shipment requires careful planning and attention to detail. It is important to use high-quality materials and follow proper packing procedures to ensure that the EV charger arrives at its destination in good condition. A professional packing and shipping company may be consulted to ensure that the machine is properly packed and prepared for sea shipment.

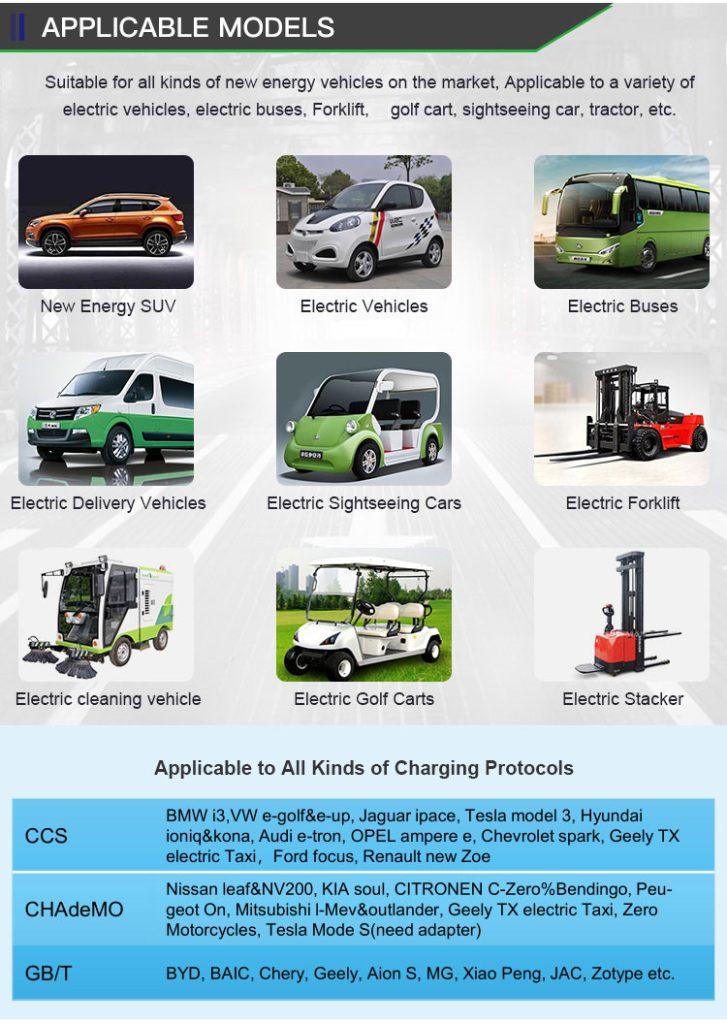

Applications of EV Charger Gun

It is appplicable for all kinds of EV Charger Gun protocols, Suitable for all kinds of new energy vehicles on the market,Applicable to a variety of electric vehicles, electric buses,Forklift,golf cartsightseeing artractor, etc.

| CHAdeMO | Nissan leaf&NV200, KIA soul, CITRONEN C-Zero%Bendingo, Peu geot On, Mitsubishi l-Mev&outlander, Geely TX electric Taxi,Zero Motorcycles, Tesla Mode S(need adapter) |

| CCS | BMW i3,VW e-golf&e-up, Jaguar ipace, Tesla model 3, Hyundai ioniq&kona, Audi e-tron, OPEL ampere e, Chevrolet spark, Geely TX electric Taxi,Ford focus, Renault new Zoe |

| GB/T | BYD, BAIC,Chery, Geely, Aion S, MG, Xiao Peng, JAC, Zotype etc. |

EV Charger Gun Level 1

EV Charger Gun Level 2

EV Charger Gun Wholesale Manufacturer In China

ChargersGO specializes in manufacturing EV Charger Gun, including charging stations, cables, and connectors. We also offer customized solutions to cater to local market preferences and requirements. Our commitment to constantly updated products, comprehensive project solutions, and efficient after-sales service sets us apart as a market leader. We strive to be China’s foremost EV charging equipment manufacturer and will continue to work tirelessly toward that goal. Our factory’s ample capacity enables large-scale production.