150KW EV Charger

Specification of 150KW EV Charger

Parameters of 150KW EV Charger:

| MODEL | 60KW | 120KW | 150KW |

| INPUT | |||

| Nominal Input Voltage | 380 VAC ± 15% | ||

| Acceptable Input Voltage Range | 3-phase, 3ph + N + PE | ||

| Working Voltage Range | 50 – 60 Hz | ||

| Maximum Input Current | 118 A | 225A | 278A |

| Frequency Range | ≦ 5% | ||

| Input Power Factor | > 0.99 @nominal voltage (100% load) | ||

| OUTPUT | |||

| Output Current Range (based on 2-output) | 2 ~ 100 A | 2 ~ 200 A | 2 ~ 250 A |

| Output Voltage Range | 200~750VDC (600~750VDC in constant power mode) | ||

| Power Module | 30kW x 2 pcs | 30kW x 4 pcs | 30kW x5 pcs |

| Efficiency | > 94% | ||

| Module Output Current Unbalancce | < 5% | ||

| Module Output Voltage Ripple | < 0.5 | ||

| Module Output Voltage Precision | < 0.5% | ||

| MModule Output Current Precision | < 1% | ||

| Connector Single Mode (max.) | CCS2 (60kW) ChAdeMO (50kW) | CCS2 (120kW) ChAdeMO (50kW) | CCS2 (150kW) ChAdeMO (50kW) |

| Connector Double Mode (max.) | CCS2 (30kW) ChAdeMO (50kW) | CCS2 (60kW) ChAdeMO (50kW) | CCS2 (90kW)ChAdeMO (50kW) |

| Power Distribution | Single plug mode / Average output mode | ||

| PROTECTION | |||

| Charger Safety Protection | Over/Under voltage, overload, output power limit function, short circuit, anti-access, earth leakage, lightning and overheat protection | ||

| Interface Safety Portection | Circuit discharge function, insulation monitoring device (IMD) and battery reverse parity protection | ||

| USER INTERFACE | |||

| Status Indiators | Power on, charging and fault | ||

| Communication Protocol | OCPP 1.6 | ||

| Connection Communication Mode | In accordance with DIN 70121 and ISO 15118 standard | ||

| Connection Standard | CCS2 (IEC61851-23) and CHAdeMO 1.0 | ||

| ENVIRONMENT | |||

| Operating Temperature | -25°C to 50°C | ||

| Humidity | 0 – 95% (non-condensing) | ||

| Altitude | < 2000m | ||

| Noise Level | <65dB | ||

| PHYSICAL | |||

| IP Protection | IP54 | ||

| Cable Length | 5m | ||

| Dimension, D x W x H (mm) | 750 x 530 x 1685, excluding plug and cable | ||

| Net Weight (kgs) | 275 | 310 | 328 |

Introduction of 150KW EV Charger

Powering the Future of Electric Vehicles!

Say hello to the revolutionary 150KW EV Charger, a cutting-edge solution that promises to transform the way we charge our electric vehicles! With its high-power capacity and advanced features, this charger is set to pave the way for a greener and more efficient future on the roads.

What makes the 150KW EV Charger stand out from the crowd is its remarkable charging speed. At a whopping 150 kilowatts, it can recharge electric vehicles at lightning-fast rates, significantly reducing the time spent waiting at charging stations. This means you can be back on the road in no time, making long journeys and commutes more convenient and hassle-free than ever before.

Designed with both performance and safety in mind, this charger incorporates state-of-the-art technology to ensure a smooth and reliable charging experience. Equipped with smart charging protocols and protective measures, it prioritizes the well-being of your vehicle’s battery, extending its life while safeguarding against overcharging and overheating.

The 150KW EV Charger is also remarkably versatile, catering to a wide range of electric vehicles with varying charging needs. Whether you own a compact electric car or a larger electric SUV, this charger is compatible and ready to meet your requirements.

Furthermore, its user-friendly interface and intuitive controls make it effortless to operate, even for those new to electric vehicles. The charger’s clear display and simple instructions guide you through the charging process, making it accessible to everyone.

But that’s not all – this charger is an eco-warrior too! By promoting the use of electric vehicles, it plays a significant role in reducing harmful emissions and combating climate change, contributing to a greener and more sustainable planet for generations to come.

In conclusion, the 150KW EV Charger is a game-changer in the world of electric vehicles. With its remarkable charging speed, safety features, and environmental benefits, it’s poised to revolutionize the way we charge and drive our cars. Embrace the future of electric mobility and join the green revolution with the 150KW EV Charger!

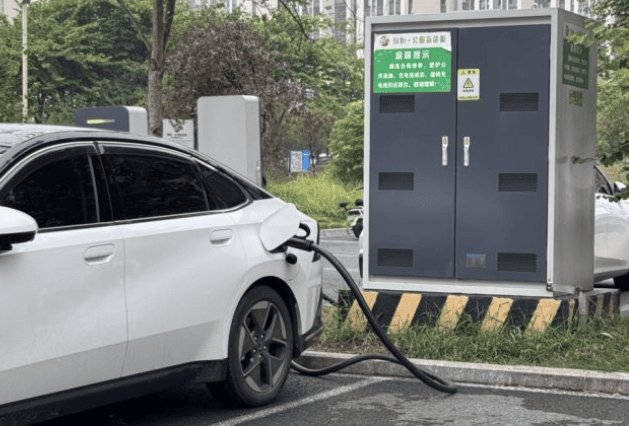

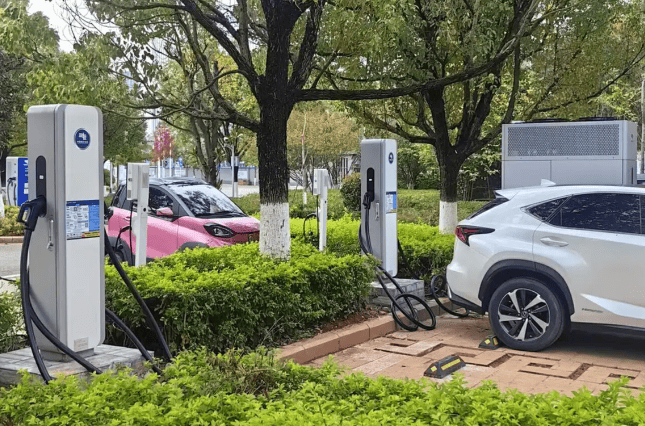

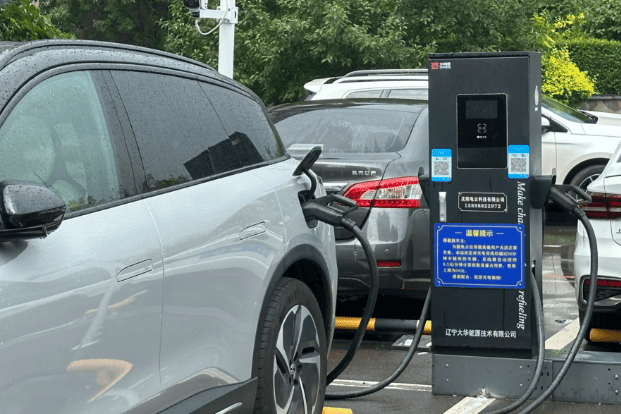

Pictures of 150KW EV Charger

Advantages of 150KW EV Charger

LCD Screen

7 inch Colored LCD Touch Display Screen, Charge Mode Can be Set

Radian Design

The Panel Adopts Radian

Design, Which Can Effectively Protect the Touch Screen

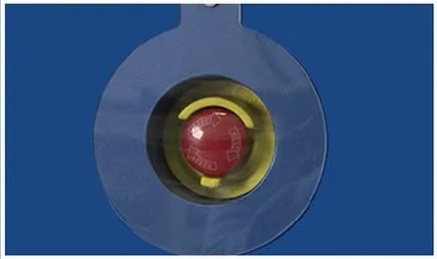

Emergency Stop Button

If Something Unexpected Happened, Please Press Red Emergency Stop Button Immediately

More advantages for 150KW EV Charger

The 150KW EV Charger offers numerous advantages that make it a game-changer in the world of electric vehicle charging. Here are some of the key benefits:

- Lightning-Fast Charging: The 150KW EV Charger’s high-power capacity enables it to charge electric vehicles at incredibly fast rates. With such rapid charging speeds, EV owners can significantly reduce the time spent waiting at charging stations, making long journeys and commutes more convenient and time-efficient.

- Reduced Downtime: Due to its quick charging capabilities, the 150KW EV Charger minimizes the downtime for electric vehicles. This is especially beneficial for commercial and fleet operators who rely on their vehicles for daily operations. Less time spent charging means more time on the road, maximizing productivity and profitability.

- Universal Compatibility: The 150KW EV Charger is designed to be compatible with a wide range of electric vehicles. From compact city cars to larger electric SUVs, this charger can cater to diverse charging needs, making it versatile and accessible for various electric vehicle owners.

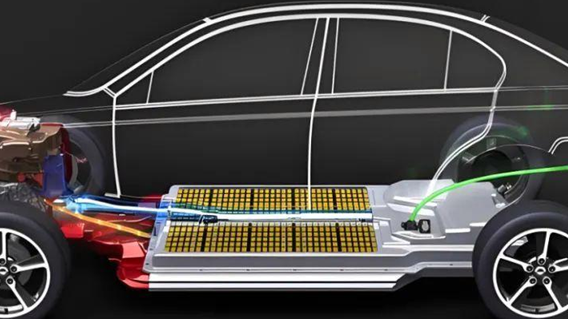

- Optimal Battery Health: The charger is equipped with advanced charging protocols and safety features that prioritize the health of the electric vehicle’s battery. By preventing overcharging and overheating, the charger helps extend the battery’s lifespan and ensures long-term performance and efficiency.

- Future-Proof Investment: As electric vehicles and charging technology continue to evolve, the 150KW EV Charger provides a future-proof charging solution. With its high-power capacity, it is well-equipped to handle the charging demands of upcoming electric vehicle models that may have larger batteries and faster charging capabilities.

- Environmentally Friendly: Embracing electric mobility is a significant step towards reducing greenhouse gas emissions and combatting climate change. By encouraging the use of electric vehicles, the 150KW EV Charger plays a vital role in promoting sustainable transportation and contributing to a cleaner, greener environment.

- User-Friendly Experience: Despite its high-power capacity, the 150KW EV Charger is designed with a user-friendly interface and intuitive controls. EV owners can easily initiate and monitor the charging process, making it accessible to both experienced electric vehicle users and those new to the technology.

- Supporting Charging Infrastructure: The adoption of the 150KW EV Charger encourages the development of a robust charging infrastructure. As more of these high-power chargers are deployed, it enhances the charging network’s efficiency and coverage, making electric vehicle adoption more feasible for a broader audience.

In summary, the 150KW EV Charger’s advantages lie in its rapid charging speed, universal compatibility, battery health protection, and its contribution to environmental sustainability. By investing in this high-power charging solution, we can pave the way for a more efficient, eco-friendly, and convenient electric vehicle charging ecosystem.

Why Choose Us?

Our EV Charger Factory Introduction

| Business Type: | Manufacturer/Factory | Main Products: | EV Charger |

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

ChargersGO Factory is a professional manufacturer for EV Charger. Our main product including slow charger, fast charger, DC EV Charger, AC EV Charger, commercial EV Charger, charger for home, EV charger level 1, level 2 and level 3 etc. All products in accordance with the China GMP design requirements. And also we have other certifications.

Business Philosophy

“Quality is the main policy of sales” and “integrity is the principle of success” are the business philosophy of our people. We carry out one-year warranty, lifelong maintenance service, with technical consultation and other services, and long-term supply of equipment. Welcome new and old customers to negotiate cooperation!

Production Process:

Producing an Electric Vehicle (EV) charger involves a series of carefully orchestrated steps to ensure the charger’s quality, safety, and performance. The production process typically consists of the following key stages:

- Design and Engineering: The process begins with the design and engineering phase. Skilled engineers and designers work together to create a blueprint for the EV charger. They consider factors like power capacity, safety features, charging protocols, and compatibility with various electric vehicle models.

- Component Sourcing: Once the design is finalized, the production team sources the necessary components and materials for the charger. These components can include circuit boards, connectors, casing materials, power modules, and safety components. Manufacturers often prioritize high-quality, reliable components to ensure the charger’s longevity and performance.

- Circuit Board Assembly: The core of an EV charger is its circuit board, which controls the charging process and ensures safe operation. Surface Mount Technology (SMT) machines precisely place electronic components onto the circuit board. Skilled technicians may also perform manual assembly for certain components that require extra care.

- Casing and Enclosure: The charger’s casing is an essential part of its design, providing protection from external elements and ensuring user safety. The casing is usually made of durable materials, such as aluminum or robust plastics. Injection molding or other manufacturing techniques are used to create the charger’s enclosure.

- Quality Control: Throughout the production process, rigorous quality control checks are conducted to identify any defects or inconsistencies. Each charger is tested at various stages to ensure its functionality and safety compliance. Quality control specialists meticulously examine the assembled units to meet industry standards.

- Safety Testing and Certifications: Before releasing the chargers to the market, they undergo rigorous safety testing and certifications. These tests may include electrical safety tests, thermal tests, and environmental tests to ensure the charger can operate reliably in different conditions.

- Final Assembly and Packaging: After successfully passing all tests and certifications, the chargers undergo final assembly and packaging. They are carefully packaged and prepared for distribution, along with user manuals and any necessary accessories.

- Distribution and Installation: The chargers are then distributed to retailers, charging network operators, or directly to end customers. Upon receiving the chargers, they are installed at charging stations or provided to electric vehicle owners for home charging.

- Customer Support and Maintenance: Once in use, manufacturers provide ongoing customer support and maintenance services to ensure the chargers continue to perform optimally. This includes troubleshooting assistance, firmware updates, and periodic inspections.

By following a well-structured production process and adhering to strict quality standards, manufacturers can produce high-quality EV chargers that contribute to the growth of electric mobility and a greener, sustainable future.

Certifications:

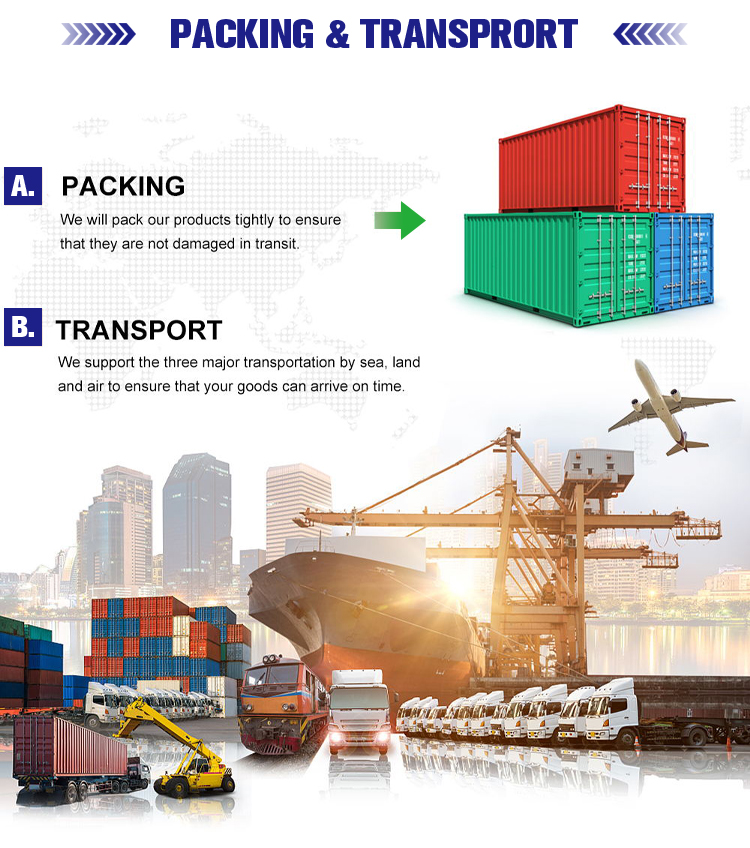

Small EV Charger Packing:

Retail Small EV Charger shipped with express.

Wsholesale Small EV Charger packed with export fumigation-free wooden cases, goes with bulk shipment or in container.

When packing small EV charger for sea shipment, it is important to take measures to ensure that the machines are protected from damage during transit. Here are some general steps that a manufacturer may follow when packing small EV charger for sea shipment:

- Clean and dry the charger: Before packing, the charger should be thoroughly cleaned and dried to prevent any moisture or debris from causing damage during transit.

- Disassemble the machine: If possible, the charger should be disassembled into its component parts to reduce its overall size and make it easier to pack.

- Wrap the charger in protective material: The charger should be wrapped in a layer of protective material, such as bubble wrap or foam, to protect it from scratches and impact during transit.

- Place the charger in a sturdy box: The wrapped charger should then be placed in a sturdy box that is appropriate for the size and weight of the machine. The box should be made of durable material, such as corrugated cardboard or plywood, and should be able to withstand the rigors of sea transit.

- Add packing material: The box should be filled with packing material, such as packing peanuts or air pillows, to provide cushioning and prevent the machine from shifting during transit.

- Seal the box: The box should be securely sealed with high-quality packing tape to prevent it from opening during transit.

- Label the box: The box should be clearly labeled with the charger’s name, weight, and any other relevant information, as well as the destination address and contact information.

Overall, the goal is to pack the small chargers in a way that will protect it from damage during transit and ensure that it arrives at its destination in good condition. It is important to follow proper packing procedures and use high-quality packing materials to minimize the risk of damage during sea shipment.

Large EV Charger Packing:

Packing a large EV charger for sea shipment can be a complex and challenging task. However, with careful planning and attention to detail, it is possible to pack a large machine for sea shipment in a way that will ensure that it arrives at its destination in good condition. Here are some general steps that a manufacturer may follow when packing up a large machine for sea shipment:

- Clean and prepare the machine: Before packing, the EV charger should be thoroughly cleaned and prepared. All fluids, such as oil or coolant, should be drained, and any loose or detachable parts should be removed.

- Disassemble the machine: If possible, the machine should be disassembled into its component parts to reduce its overall size and make it easier to pack. Each part should be carefully labeled and numbered to ensure that it can be easily reassembled at the destination.

- Protect delicate parts: Delicate or fragile parts should be wrapped in protective material, such as bubble wrap or foam, to protect them from damage during transit.

- Build a custom crate: A custom crate should be built around the machine to provide a secure and sturdy enclosure. The crate should be made of durable material, such as plywood, and should be designed to fit the machine snugly. The crate should also include braces or supports to prevent the machine from shifting during transit.

- Add cushioning material: The crate should be filled with cushioning material, such as packing peanuts or air pillows, to provide extra protection and prevent the machine from moving or shifting during transit.

- Securely fasten the machine: The EV charger should be securely fastened to the crate to prevent it from moving or shifting during transit. This may involve using straps, bolts, or other fasteners to hold the machine in place.

- Seal and label the crate: The crate should be securely sealed with high-quality packing tape, and should be clearly labeled with the machine’s name, weight, and any other relevant information. The destination address and contact information should also be clearly marked on the crate.

Overall, packing a large EV charger for sea shipment requires careful planning and attention to detail. It is important to use high-quality materials and follow proper packing procedures to ensure that the EV charger arrives at its destination in good condition. A professional packing and shipping company may be consulted to ensure that the machine is properly packed and prepared for sea shipment.

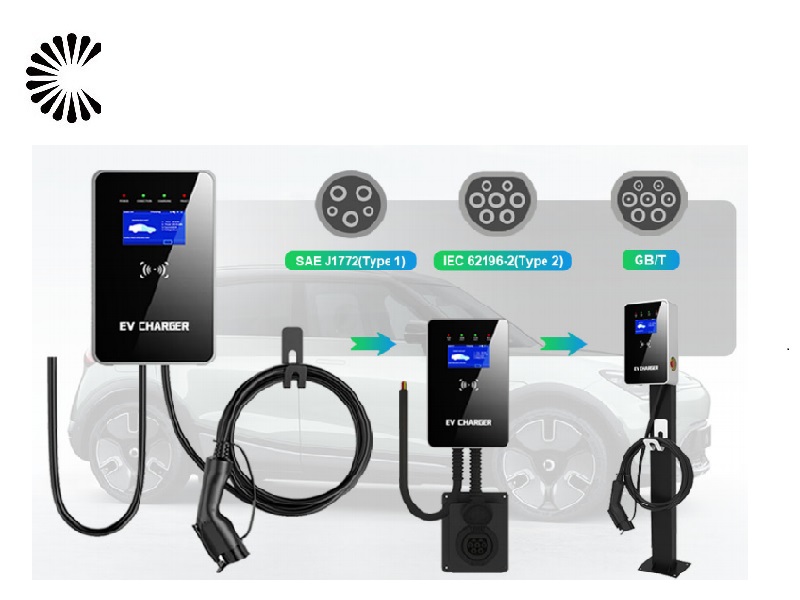

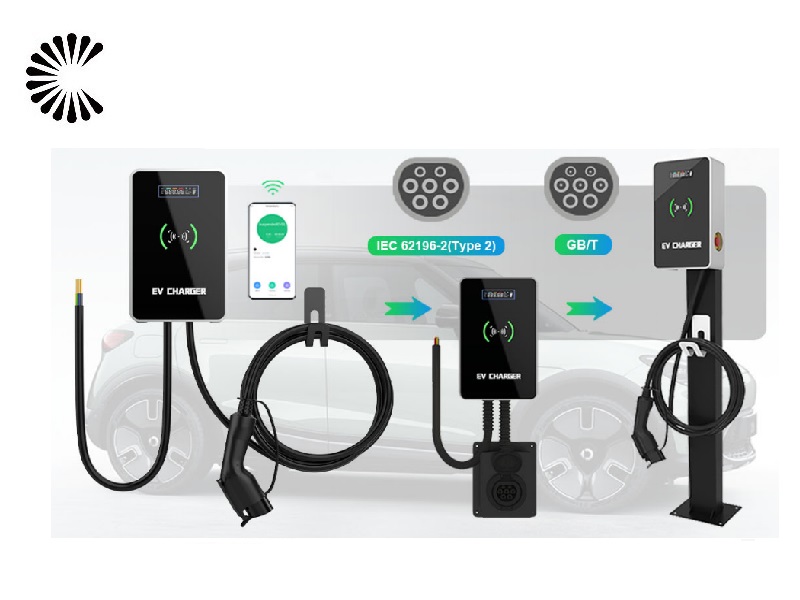

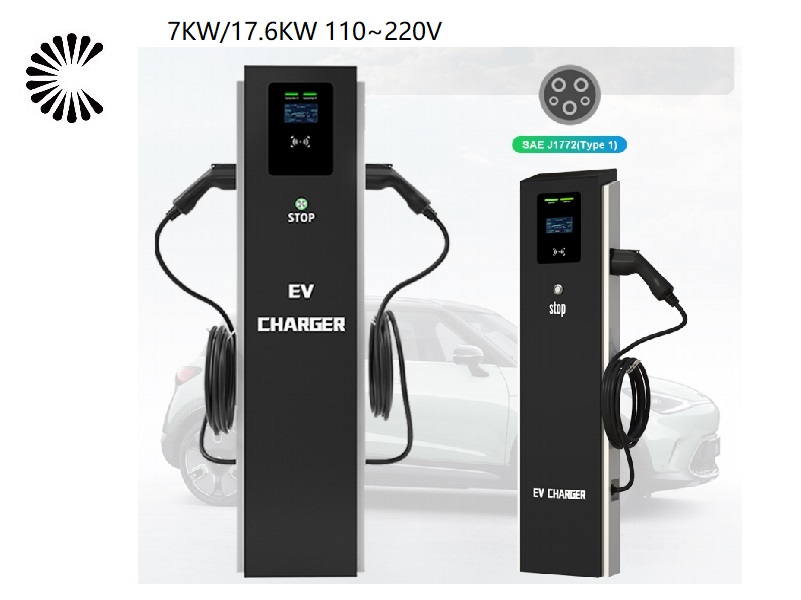

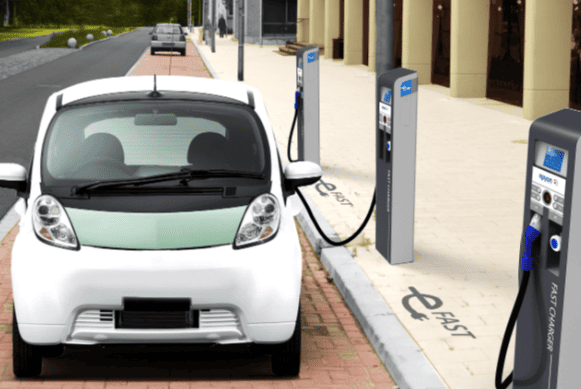

Applications of 150KW EV Charger

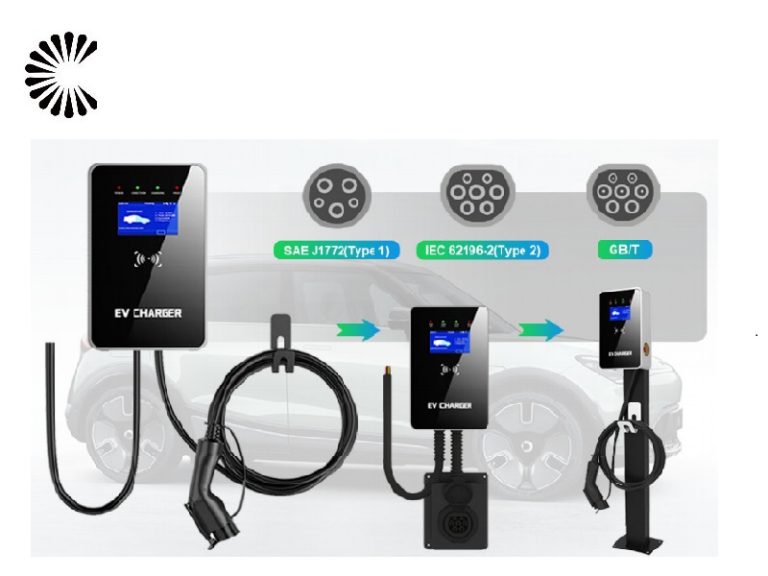

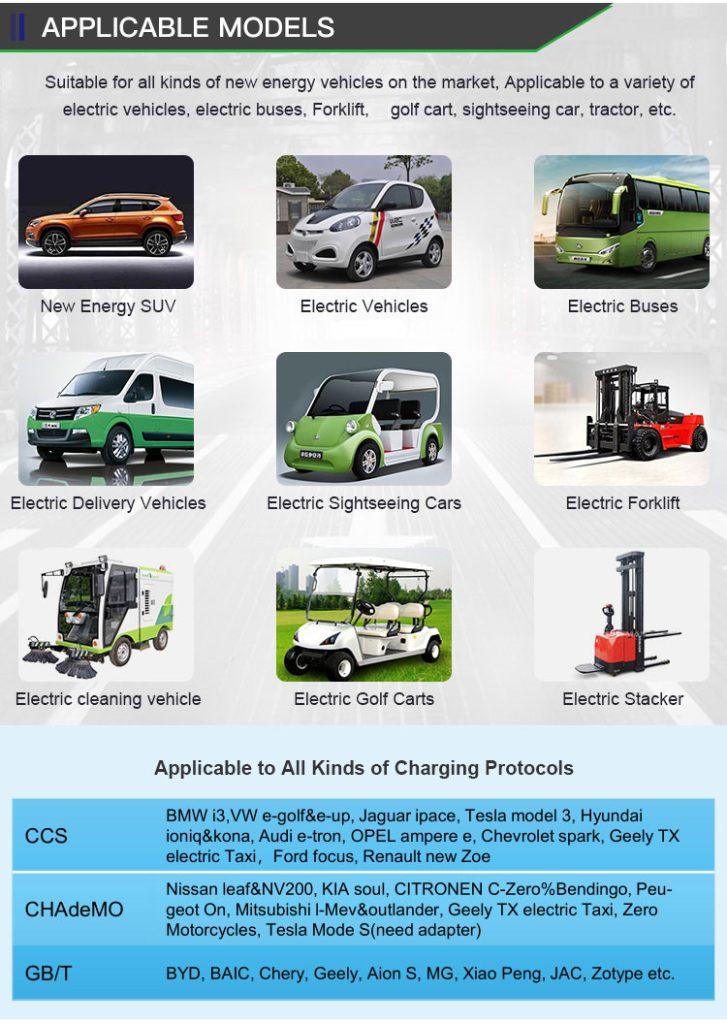

It is appplicable for all kinds of charing protocols, Suitable for all kinds of new energy vehicles on the market,Applicable to a variety of

electric vehicles, electric buses,Forklift,golf cartsightseeing cartractor, etc.

| CHAdeMO | Nissan leaf&NV200, KIA soul, CITRONEN C-Zero%Bendingo, Peu geot On, Mitsubishi l-Mev&outlander, Geely TX electric Taxi,Zero Motorcycles, Tesla Mode S(need adapter) |

| CCS | BMW i3,VW e-golf&e-up, Jaguar ipace, Tesla model 3, Hyundai ioniq&kona, Audi e-tron, OPEL ampere e, Chevrolet spark, Geely TX electric Taxi,Ford focus, Renault new Zoe |

| GB/T | BYD, BAIC,Chery, Geely, Aion S, MG, Xiao Peng, JAC, Zotype etc. |

150KW EV Charger Wholesale Manufacturer In China

As a leading 150KW EV Charger manufacturer, we take pride in providing cutting-edge charging solutions for electric vehicles. With a focus on quality and innovation, we ensure that our chargers meet the highest industry standards, delivering rapid and reliable charging experiences. Our team of dedicated engineers works tirelessly to enhance the efficiency and user-friendliness of our products, promoting sustainable transportation for a greener future. From public charging stations to private installations, we cater to diverse needs, empowering EV drivers to embrace a cleaner, more sustainable lifestyle. Join us in driving the electric revolution forward with our state-of-the-art charging solutions.

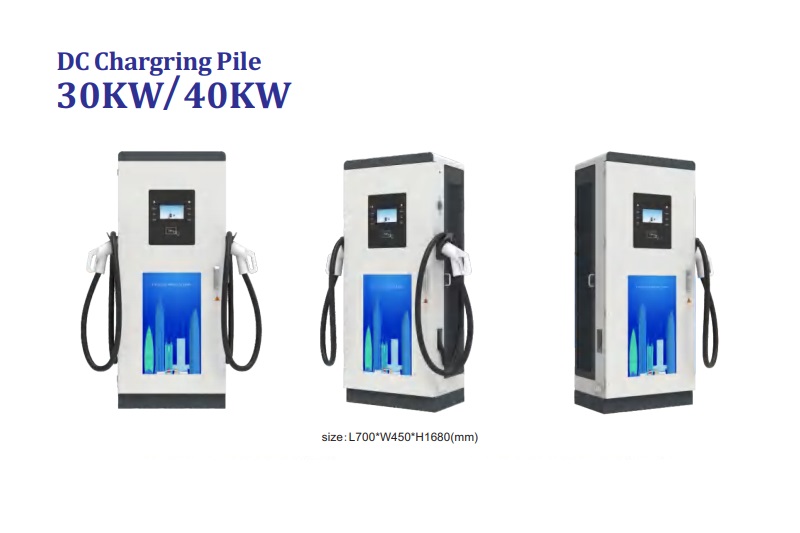

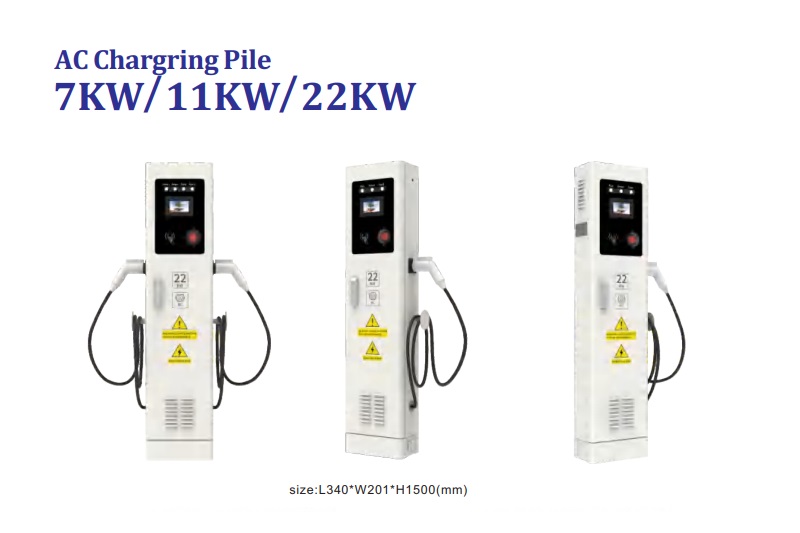

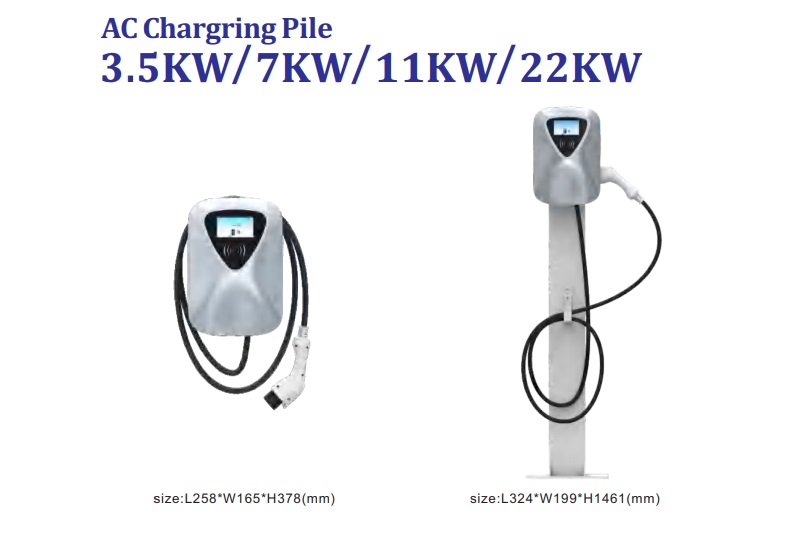

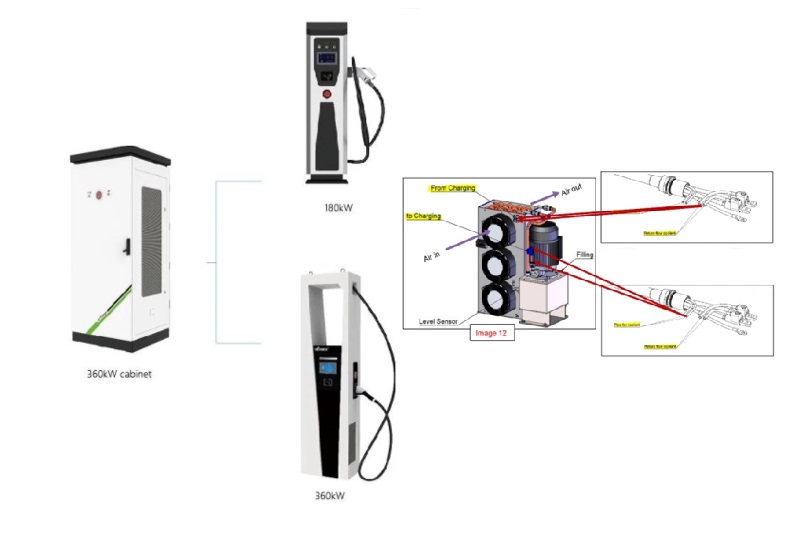

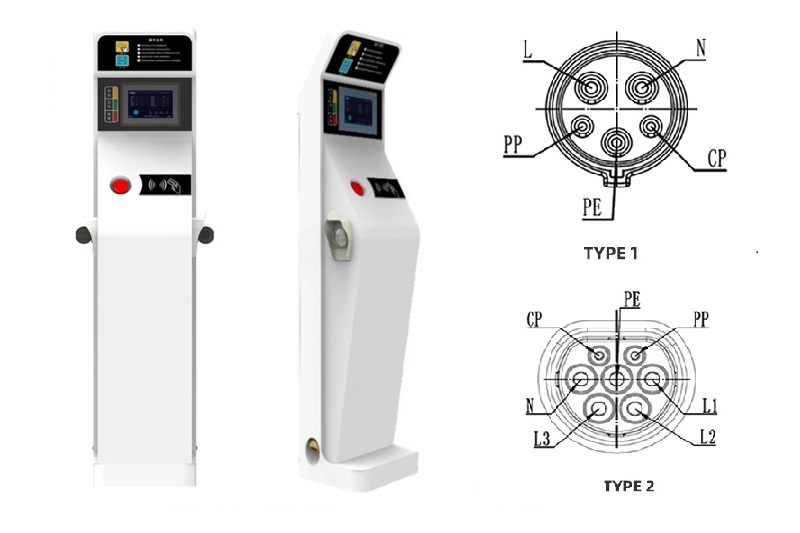

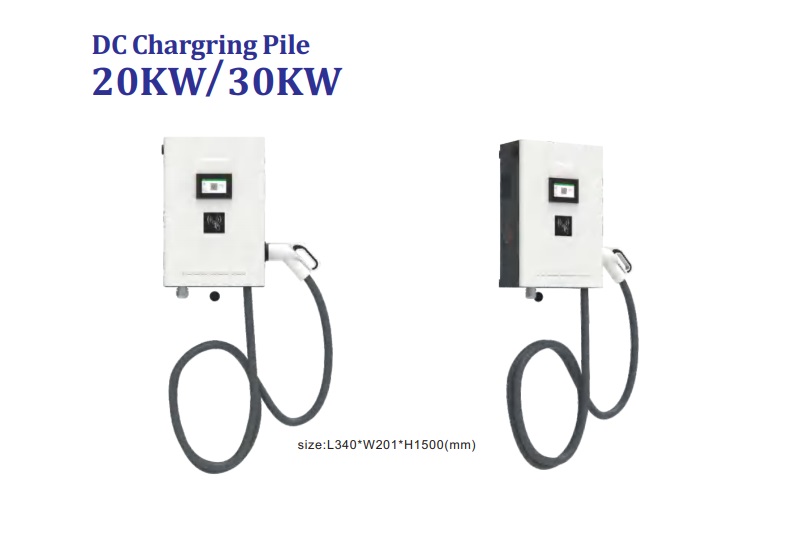

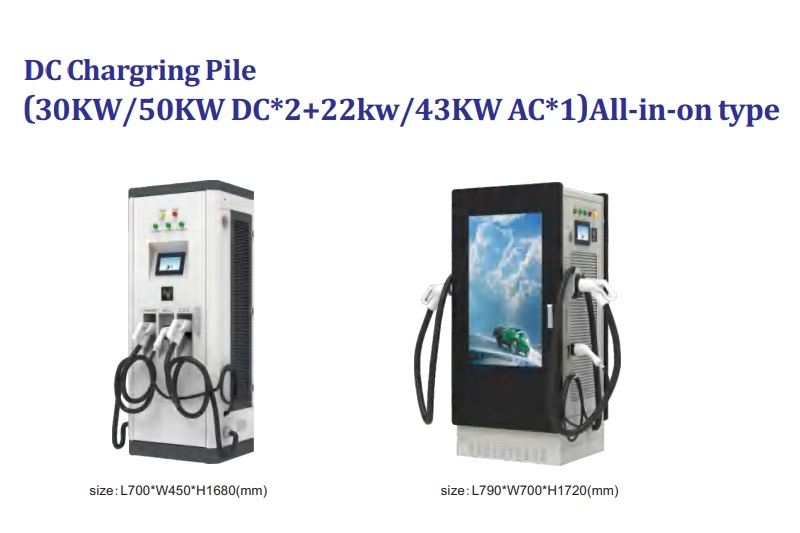

Related Products

Related Articles

Contact Us

Frequently Asked Questions (Click to see more FAQ)

-

Are you a factory or trading company?

We are a professional manufacturer of new and sustainable energy applications for over 20 years.

-

What is the warranty?

Warranty period is 12 months. In this period, we will supply technical support and replace the new parts by free,customers are in charge of delivery.

-

What is the packing method?

Generally, we pack our goods in brown cartons. If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

-

What is your terms of payment?

T/T 50% as deposit, and 50% before delivery. We’ll show you the photos of the products and packages before you pay the balance.

-

What is your terms of trade?

EXW, FOB, CFR, CIF, DAP,DDU,DDP

-

How about your delivery time?

Generally, it will take 3 to 7 working days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

-

Can you produce according to the samples?

Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

-

What is your sample policy?

We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

-

Do you test all your goods before delivery?

Yes, we have 100% test before delivery.

-

What’s the difference between Movable Charger and Wallbox Charger?

In addition to the obvious appearance difference, the main protection level is different: wallbox charger protection level is IP54, available outdoors;And the Movable Charger protection level is IP43, rainy days and other weather can not be used outdoors.

-

How fast does a 150kW charger charge?

The 150KW EV Charger offers numerous advantages that make it a game-changer in the world of electric vehicle charging. Here are some of the key benefits:

Lightning-Fast Charging: The 150KW EV Charger’s high-power capacity enables it to charge electric vehicles at incredibly fast rates. With such rapid charging speeds, EV owners can significantly reduce the time spent waiting at charging stations, making long journeys and commutes more convenient and time-efficient.

Reduced Downtime: Due to its quick charging capabilities, the 150KW EV Charger minimizes the downtime for electric vehicles. This is especially beneficial for commercial and fleet operators who rely on their vehicles for daily operations. Less time spent charging means more time on the road, maximizing productivity and profitability.

Universal Compatibility: The 150KW EV Charger is designed to be compatible with a wide range of electric vehicles. From compact city cars to larger electric SUVs, this charger can cater to diverse charging needs, making it versatile and accessible for various electric vehicle owners.

Optimal Battery Health: The charger is equipped with advanced charging protocols and safety features that prioritize the health of the electric vehicle’s battery. By preventing overcharging and overheating, the charger helps extend the battery’s lifespan and ensures long-term performance and efficiency.

Future-Proof Investment: As electric vehicles and charging technology continue to evolve, the 150KW EV Charger provides a future-proof charging solution. With its high-power capacity, it is well-equipped to handle the charging demands of upcoming electric vehicle models that may have larger batteries and faster charging capabilities.

Environmentally Friendly: Embracing electric mobility is a significant step towards reducing greenhouse gas emissions and combatting climate change. By encouraging the use of electric vehicles, the 150KW EV Charger plays a vital role in promoting sustainable transportation and contributing to a cleaner, greener environment.

User-Friendly Experience: Despite its high-power capacity, the 150KW EV Charger is designed with a user-friendly interface and intuitive controls. EV owners can easily initiate and monitor the charging process, making it accessible to both experienced electric vehicle users and those new to the technology.

Supporting Charging Infrastructure: The adoption of the 150KW EV Charger encourages the development of a robust charging infrastructure. As more of these high-power chargers are deployed, it enhances the charging network’s efficiency and coverage, making electric vehicle adoption more feasible for a broader audience.

In summary, the 150KW EV Charger’s advantages lie in its rapid charging speed, universal compatibility, battery health protection, and its contribution to environmental sustainability. By investing in this high-power charging solution, we can pave the way for a more efficient, eco-friendly, and convenient electric vehicle charging ecosystem. -

What does 150kW charger mean?

A 150 kW charger refers to an electric vehicle (EV) charger with a power capacity of 150 kilowatts. The “kW” stands for kilowatts, which is a unit of power used to measure the rate at which electrical energy is transferred or consumed.

In the context of EV charging, the power capacity of the charger determines how quickly it can recharge an electric vehicle’s battery. A 150 kW charger is considered a high-power charger, capable of delivering a significant amount of electricity to the vehicle’s battery in a short amount of time.

To put it simply, a 150 kW charger can charge an electric vehicle at a rate of 150 kilowatts per hour. The higher the charger’s power capacity, the faster the charging process, reducing the time required to replenish the vehicle’s battery.

High-power chargers like the 150 kW charger are particularly useful for long-distance travel or quick pit stops during road trips. They enable electric vehicle owners to charge their vehicles rapidly, making electric mobility more convenient and practical for everyday use.

As electric vehicle technology continues to advance, high-power chargers like the 150 kW charger play a crucial role in supporting the growth of electric mobility and fostering a cleaner, greener transportation future. -

What voltage for 150kW charger?

The voltage for a 150 kW charger typically depends on the specific design and specifications of the charger. Electric vehicle (EV) chargers can operate at various voltage levels, but the most common ones for high-power chargers like the 150 kW charger are 400-480 volts for direct current (DC) fast charging.

DC fast chargers, also known as Level 3 chargers, are capable of delivering high-power charging rates to quickly recharge electric vehicle batteries. They are commonly used for fast-charging stations along highways, at public charging stations, and in commercial settings.

While the typical voltage range for a 150 kW DC fast charger is around 400-480 volts, it’s important to note that different manufacturers or regions may have slightly different voltage specifications based on their electrical infrastructure and safety standards.

As electric vehicle technology continues to evolve, it’s possible that new charger designs may emerge with different voltage requirements or innovative charging capabilities. Therefore, when considering a 150 kW charger or any EV charger, it’s essential to review the manufacturer’s specifications and ensure compatibility with the local electrical system and the electric vehicles you intend to charge. -

How long does a 150kW charger take to charge a car?

The time it takes for a 150 kW charger to charge a car depends on the battery capacity of the vehicle and its current state of charge. Charging time is typically measured in kilowatt-hours (kWh) and can vary from one electric vehicle to another.

To estimate the charging time using a 150 kW charger, you can use the following formula:

Charging Time (in hours) = Battery Capacity of the Electric Vehicle (in kWh) / Charging Rate of the EV Charger (in kW)

For example, let’s say an electric vehicle has a battery capacity of 60 kWh and is connected to a 150 kW charger:

Charging Time = 60 kWh / 150 kW ≈ 0.4 hours

In this case, it would take approximately 0.4 hours (or 24 minutes) to fully charge the electric vehicle using the 150 kW charger.

It’s important to note that the actual charging time may vary depending on the electric vehicle’s battery capacity and the state of charge. Additionally, some electric vehicles may not be able to accept the full 150 kW charging rate, and the charging speed might be limited by the vehicle’s onboard charging system.

The 150 kW charger’s high-power capacity allows for rapid charging, making it ideal for long-distance travel or quick charging stops during road trips. However, charging times will vary depending on the specific electric vehicle being charged and its battery characteristics. It’s always a good idea to refer to the vehicle manufacturer’s specifications for more precise charging time estimates.