Single Gun AC Slow Charging Pile Wholesale

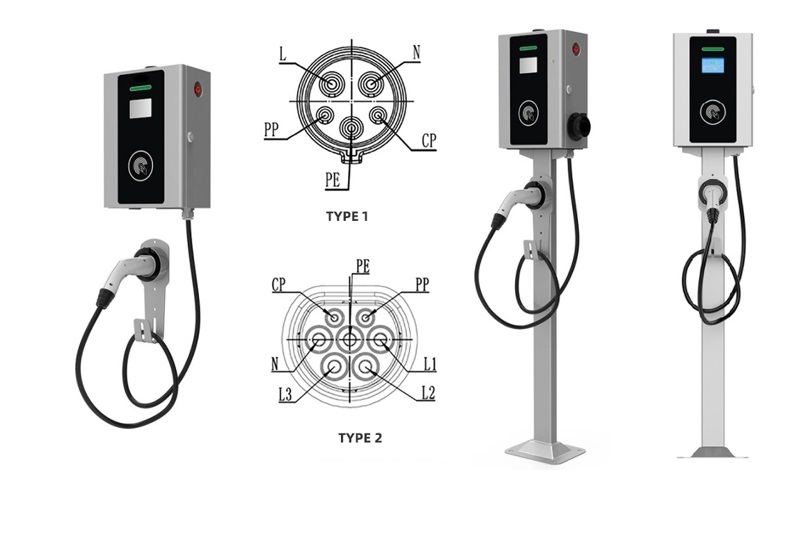

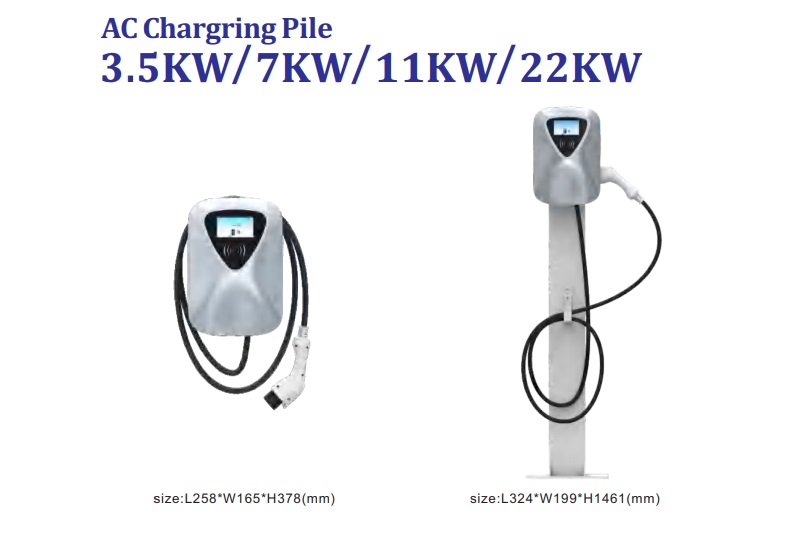

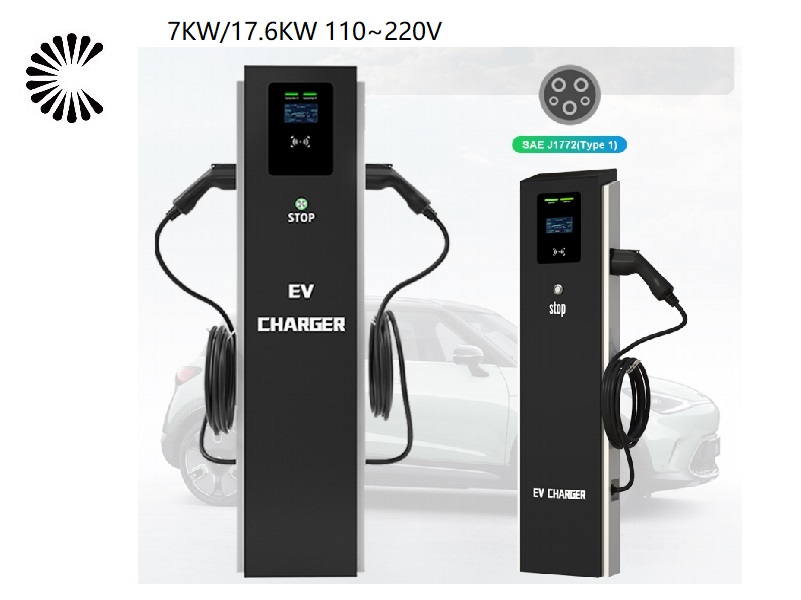

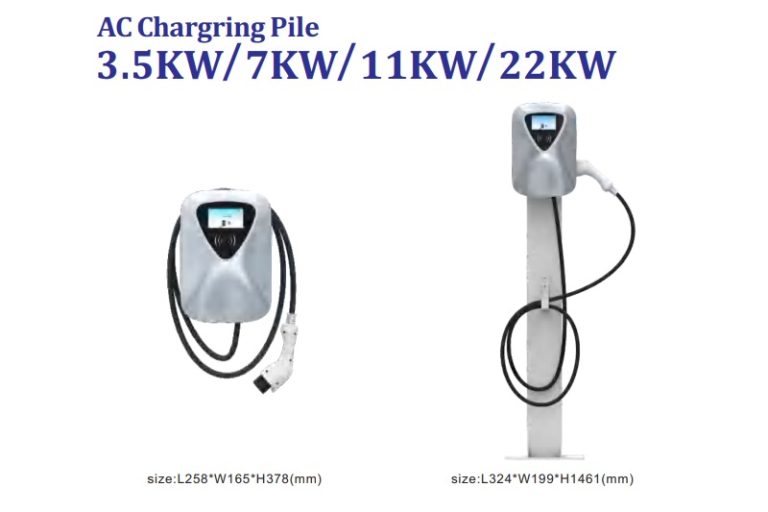

Wallbox Floor AC Charger 3.6~22KW 220/380V

Specification of AC EV Charger

Lead time:

| Quantity (pieces) | 1 – 1 | 2 – 10 | > 10 |

| Lead time (days) | 7 | 15 | To be negotiated |

Parameters of AC EV Charger:

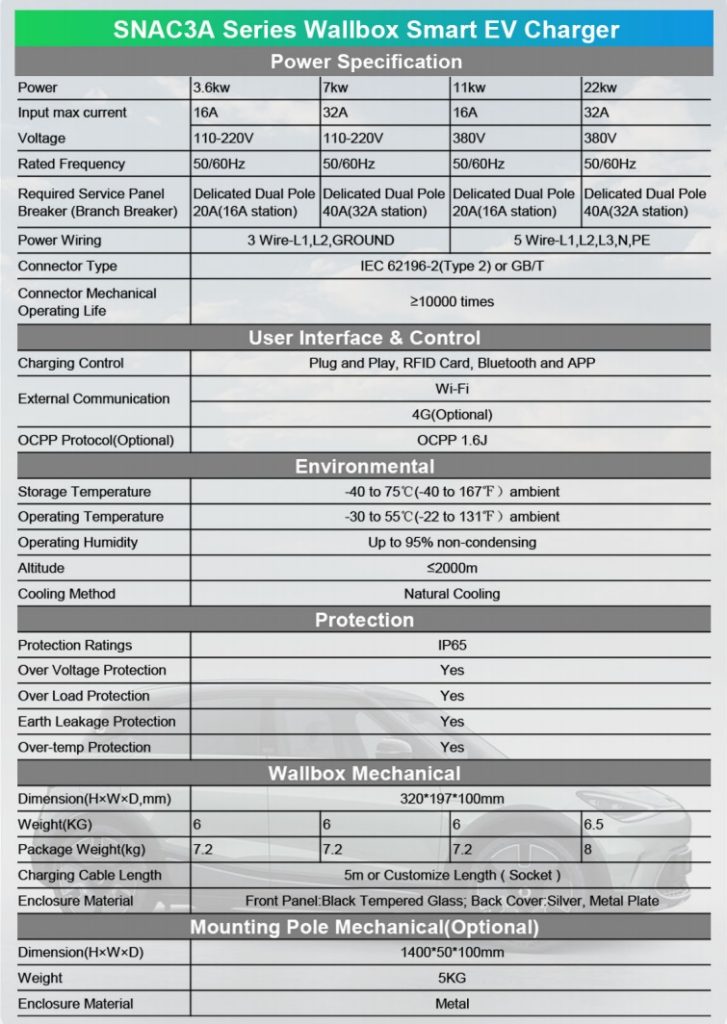

Power Specification

| Power | 3.6KW | 7KW | 11KW | 22KW |

| Input Max Voltage | 16A 220V | 32A 220V | 16A 380V | 32A 380V |

| Rated Frequency | 50/60 HZ | 50/60 HZ | 50/60 HZ | 50/60 HZ |

| Required Service Panel Breaker(Branch Breaker) | Delicated Dule Pole 20A(16A Station) | Delicated Dule Pole 40A(32A Station) | Delicated Dule Pole 20A(16A Station) | Delicated Dule Pole 40A(32A Station) |

| Power Wiring | 3 Wire-L1, L2, Ground | 3 Wire-L1, L2, Ground | 5 Wire-L1, L2, L3, N, PE | 5 Wire-L1, L2, L3, N, PE |

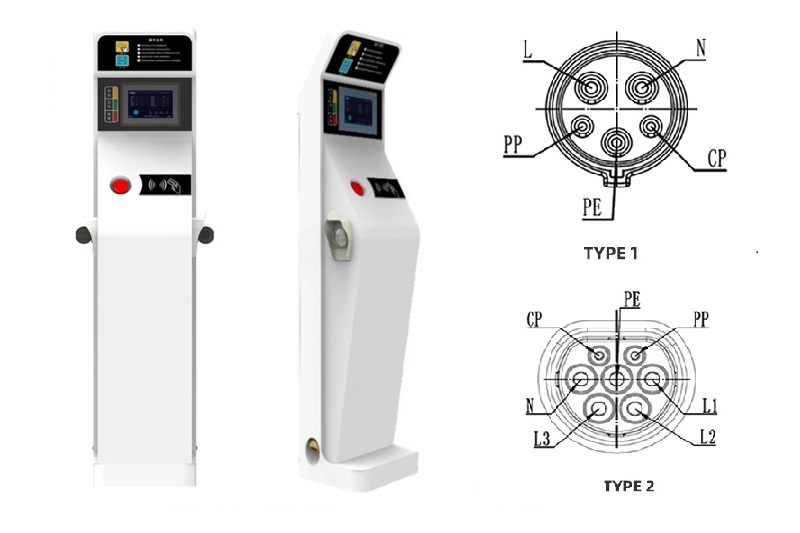

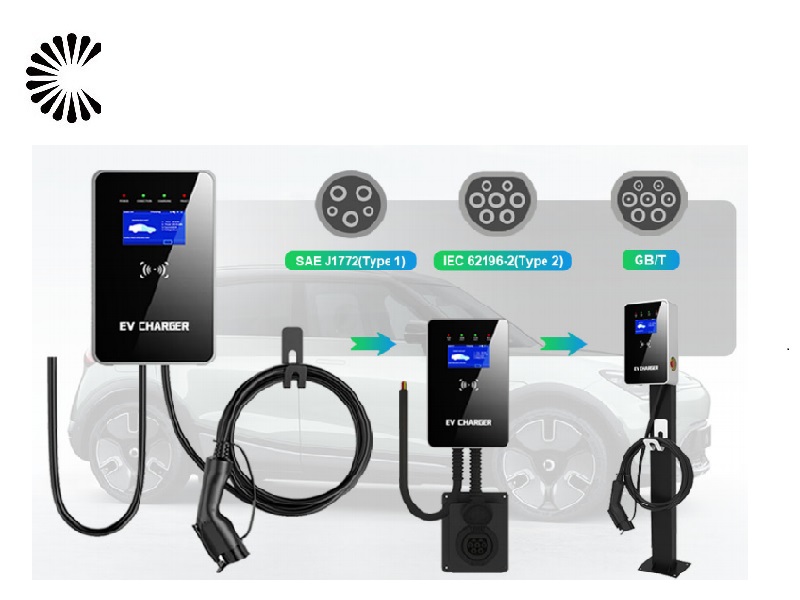

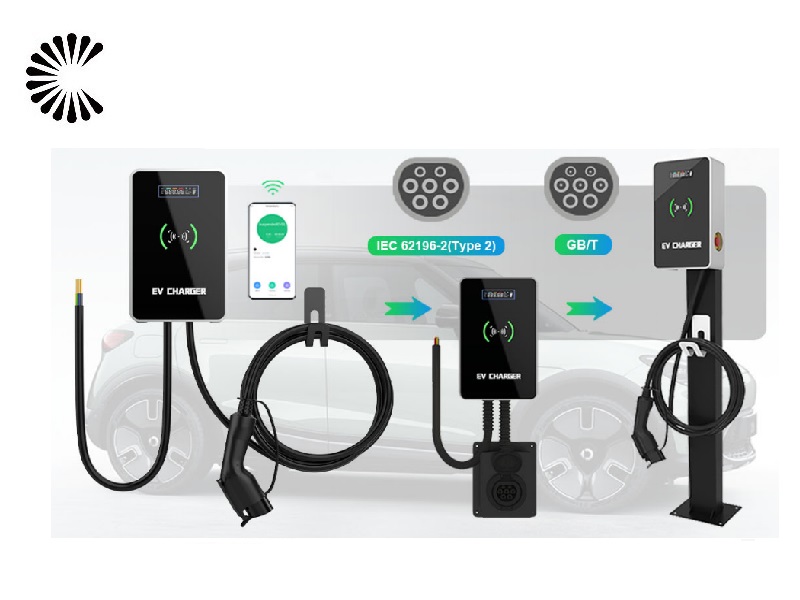

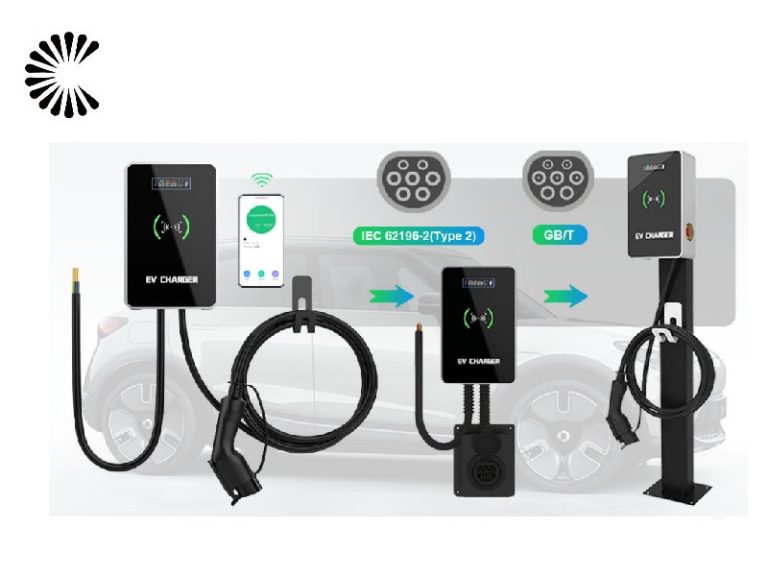

| Connector Type | SAE J1772(Type1) or IEC 62196-2(Type 2) or GB/T | SAE J1772(Type1) or IEC 62196-2(Type 2) or GB/T | IEC62196-2(Type 2) or GB/T | IEC62196-2(Type 2) or GB/T |

| Item Name | Paramters |

| Connector Mechanical Oprating Life | ≥10000 times |

| Display Screen | 4.3 inch LCD Screen |

| Indicators | 4 LED indicators – Power/ Connect/Charging/Fault |

User Interface &Control & Environmental

| Charging Control | Plug and play, RFID Card |

| Storage Temperature | -40 to 75℃(-40 to 167℉)ambient |

| Operating Temperature | -30 to 55℃(-22 to 131℉)ambient |

| Operating Humidity | Up to 95% non-condensing |

| Altitude | ≤2000m |

| Cooling Method | Natural Cooling |

| Protection Rating | IP65 |

| Over Voltage Protection | Yes |

| Over Load Protection | Yes |

| Earth Leakage Protection | Yes |

| Over-temp Protection | Yes |

Wallbox Mechanical Parameters:

| Dimension: | 320*197*100mm |

| Charging Cable Length: | 5m or Customize Length (Socket) |

| Enclosure Material | Front Panel: black tempered glasee; black cover; metal plpate |

Floor Mounting Pile Mechanical Parameters:

| Dimension(H*W*D) | 1400*50*100(mm) |

| Weight | 5KG |

| Enclosure Material | Metal |

Introduction of AC EV Charger:

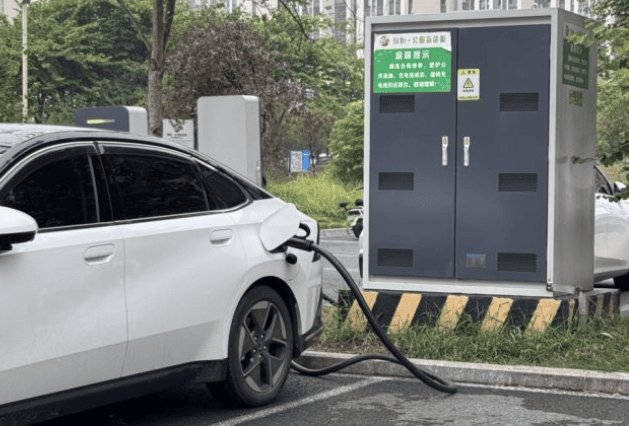

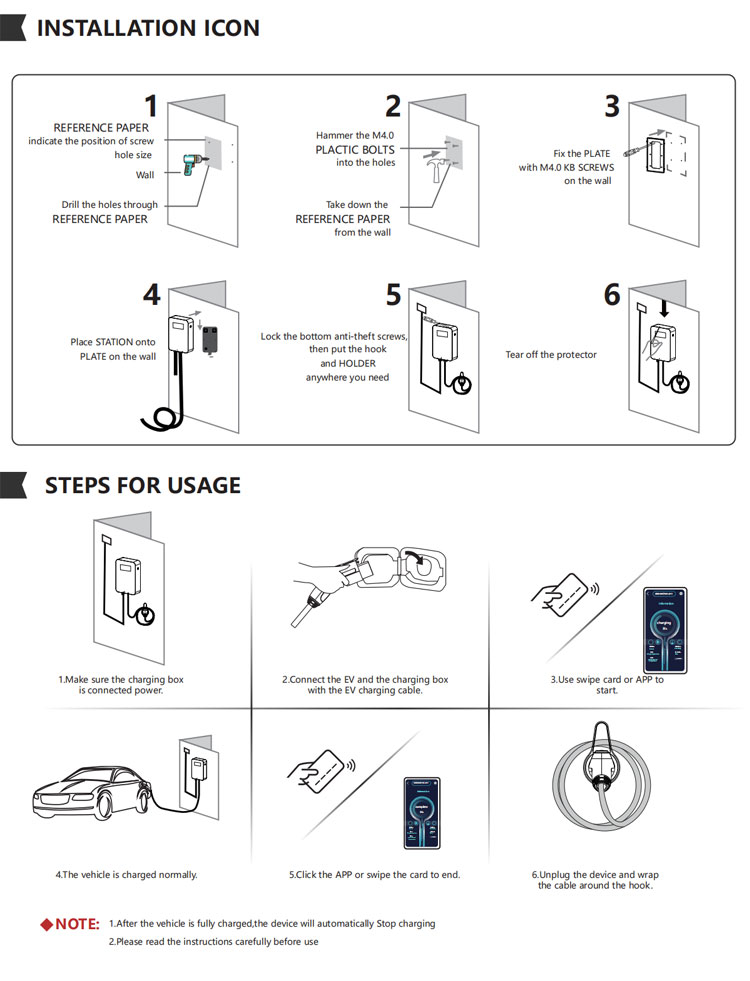

Welcome to the world of electric vehicles! Today, we are thrilled to introduce the AC EV Charger, a state-of-the-art charging solution that brings convenience and efficiency to your electric driving experience.

The AC EV Charger is an advanced electric vehicle charging station designed to power up your electric car using alternating current (AC) power. With its cutting-edge technology and user-friendly features, this charger provides a reliable and seamless charging experience for all EV owners.

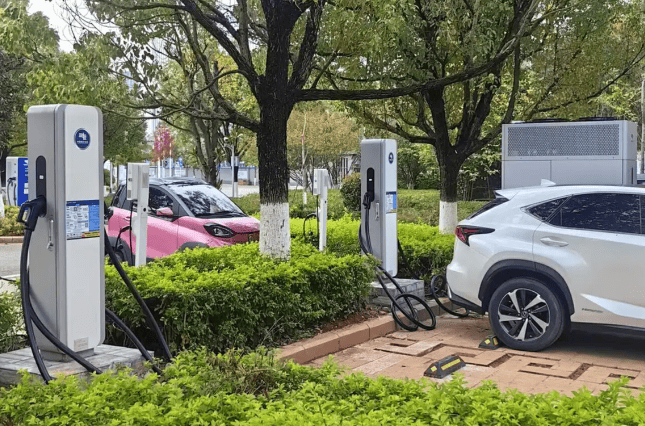

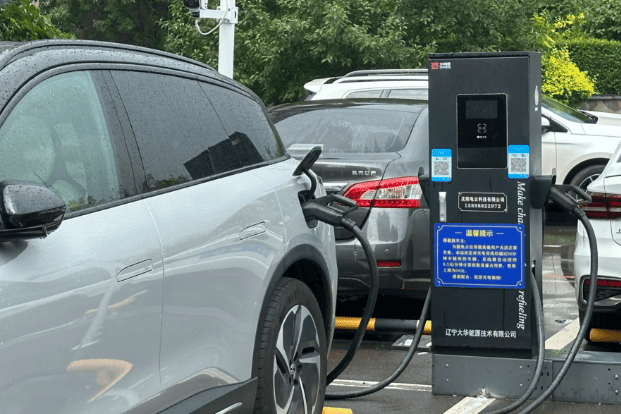

Designed for versatility and ease of use, the AC EV Charger is compatible with a wide range of electric vehicle models. Whether you drive a compact car or a spacious electric SUV, this charging station can handle them all, making it a perfect fit for any EV owner.

Its smart and intuitive interface ensures that charging your electric vehicle is as easy as plugging in and getting on with your day. The AC EV Charger offers various charging modes, allowing you to adjust the charging speed according to your needs and electrical capacity.

Safety is a top priority with the AC EV Charger. Equipped with advanced safety features, including protection against overcurrent and overheating, you can charge your EV with peace of mind, knowing that it is in safe hands.

The sleek and modern design of the AC EV Charger makes it an attractive addition to any home, office, or public charging station. Its compact form factor ensures it won’t take up much space while providing a crucial service in your electric driving journey.

Embrace the future of transportation with the AC EV Charger and join the growing community of eco-conscious drivers. With this efficient charging solution, you can effortlessly power up your electric vehicle, reducing your carbon footprint and contributing to a cleaner and more sustainable environment.

Experience the convenience and reliability of the AC EV Charger and take the first step towards a greener and more efficient way of driving. Embrace the future of electric mobility and let the AC EV Charger be your trusted partner in electrifying your daily journeys.

Advantages of AC EV Charger

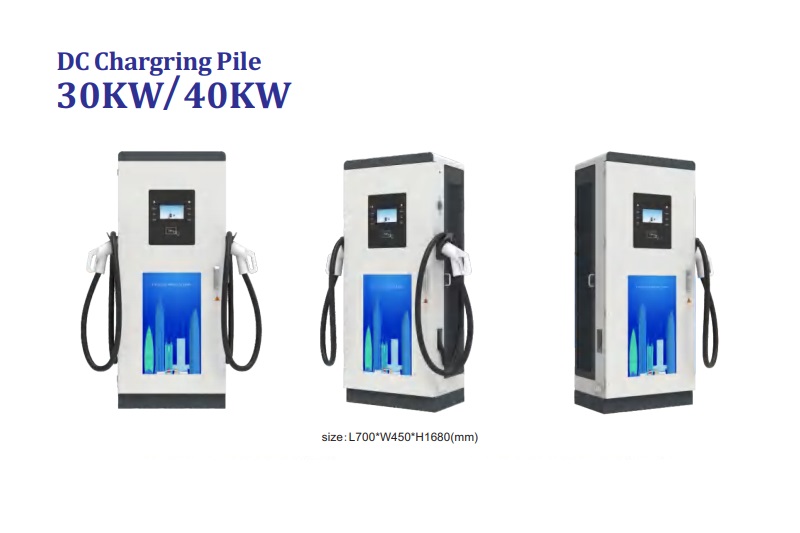

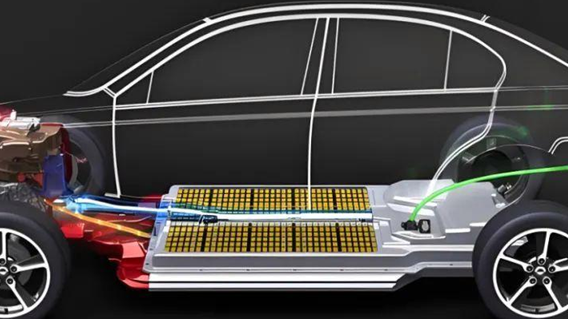

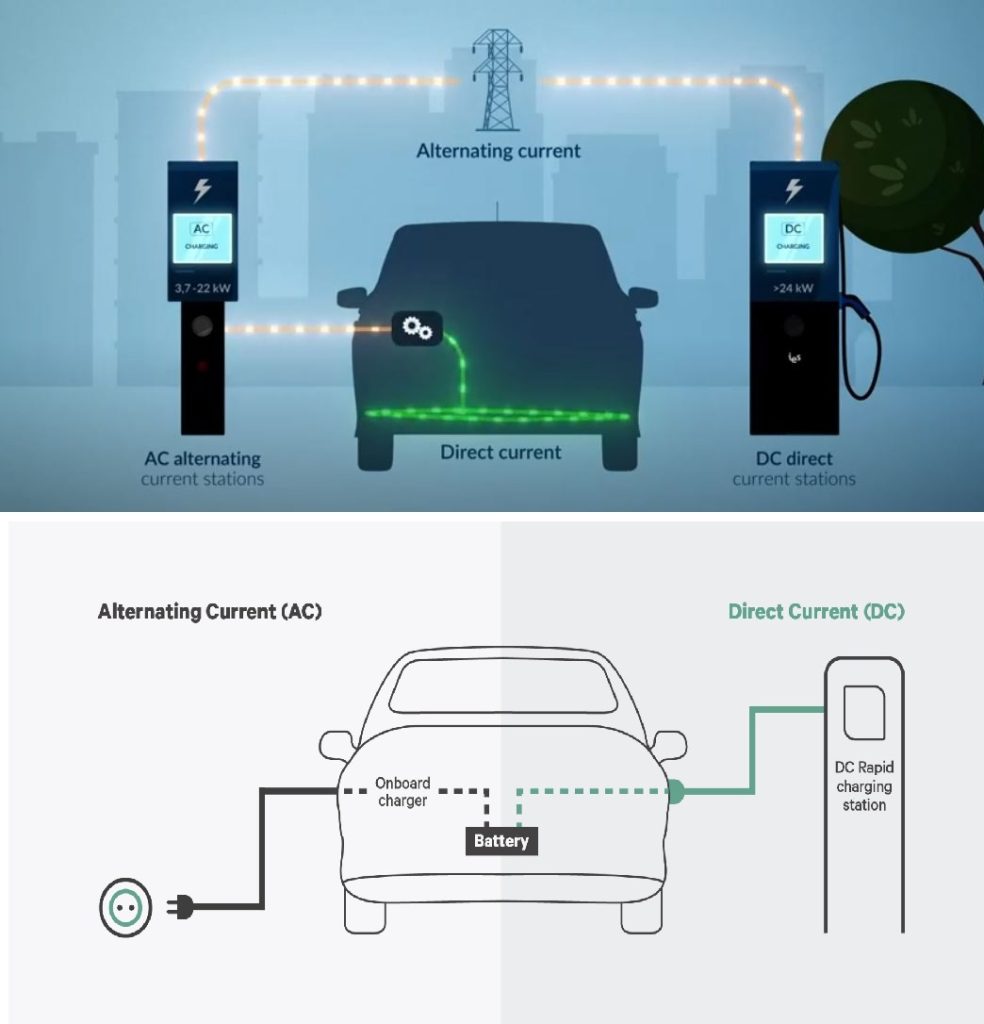

Electric car charging piles come in two types: AC charging piles and DC charging piles. To understand their advantages and disadvantages, let’s first explore the difference between direct current (DC) and alternating current (AC).

In DC, electric charge flows in one direction due to a rotating magnet along the wire, while in AC, the electric current changes direction periodically because of steady magnetism along the wire. AC current is safer for long-distance travel as it experiences smaller energy losses compared to DC, which can only travel far until it begins to lose energy.

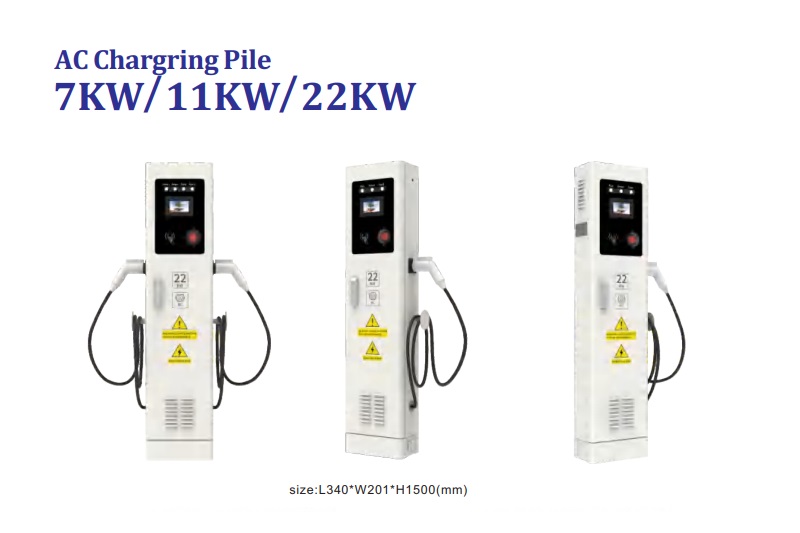

Advantages of AC EV Charger:

- Most Common Method: AC charging with a plug is the most common method for electric vehicles. The converter is built inside the vehicle, converting AC to DC before feeding it into the battery.

- Suitable for Parking Spots: AC EV Charger is suitable for parking spots where vehicles stay parked for longer durations.

- Cost-Effective: AC generation, installation, and operation are cheaper than DC.

- Robust and Easy Maintenance: AC EV Charger are robust and require less maintenance.

- Easy Conversion: AC can easily be converted into DC using rectifiers or transformers.

- Minor Line Losses: AC supplied at higher voltages results in minor line losses for longer city distances.

Advantages of DC Charging:

- Direct Power Supply: DC chargers can directly feed power to the car’s battery without the need for an onboard converter, making them faster.

- Faster Charging: DC chargers are bigger and faster, making them suitable for quick charging during long-distance travel.

- No Need for Onboard Converter: DC chargers bypass the vehicle’s converter, enabling efficient power delivery to the car battery.

- Suitable for Certain Uses: DC is ideal for charging certain batteries, electric traction, and applications like electroplating.

- Faster Charging Speed: DC charging can add up to 400km in 15 minutes for supported vehicles.

- In conclusion, AC EV Charger are more affordable, widespread, and suitable for home installation and night charging. DC chargers, on the other hand, offer much faster charging but are technologically complex, more expensive, and require powerful grid connections. DC fast charging is a growing trend, but it will not replace AC slow charging entirely. High-quality battery technology and safety are crucial for effective DC charging.

| Business Type: | Manufacturer/Factory | Main Products: | EV Charger |

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

ChargersGO is a professional manufacturer for EV Charger. Our main product including slow charger, fast charger, DC EV Charger, AC EV Charger, commercial EV Charger, charger for home, EV charger level 1, level 2 and level 3 etc. All products in accordance with the China GMP design requirements. And also we have other certifications.

Business Philosophy

“Quality is the main policy of sales” and “integrity is the principle of success” are the business philosophy of our people. We carry out one-year warranty, lifelong maintenance service, with technical consultation and other services, and long-term supply of equipment. Welcome new and old customers to negotiate cooperation!

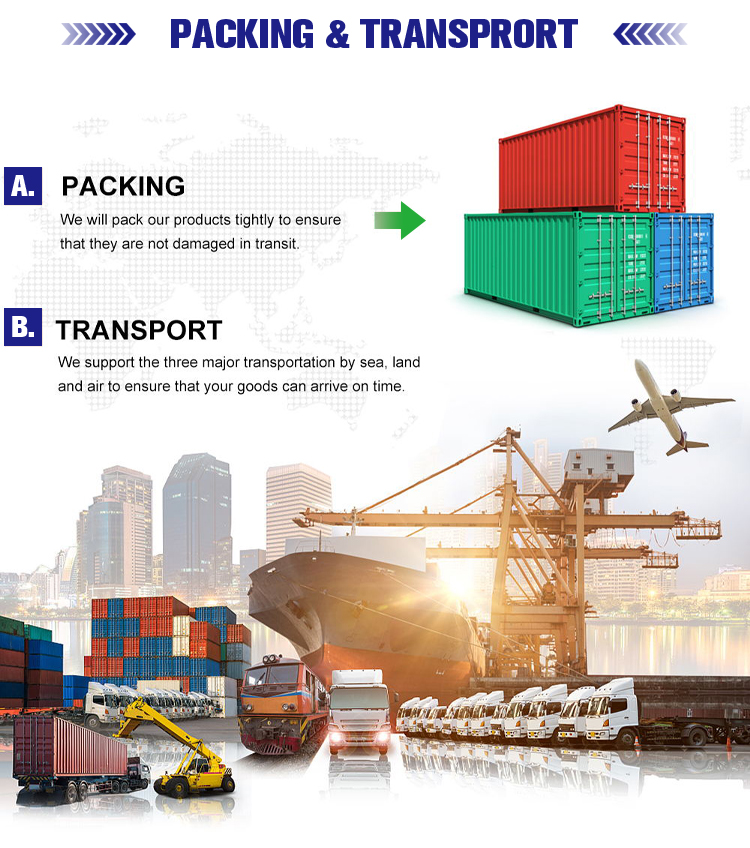

Small EV Charger Packing:

Retail Small EV Charger shipped with express.

Wsholesale Small EV Charger packed with export fumigation-free wooden cases, goes with bulk shipment or in container.

When packing small EV Charger for sea shipment, it is important to take measures to ensure that the EV Chargers are protected from damage during transit. Here are some general steps that a manufacturer may follow when packing small EV Charger for sea shipment:

- Clean and dry the charger: Before packing, the charger should be thoroughly cleaned and dried to prevent any moisture or debris from causing damage during transit.

- Disassemble the EV Charger : If possible, the charger should be disassembled into its component parts to reduce its overall size and make it easier to pack.

- Wrap the charger in protective material: The charger should be wrapped in a layer of protective material, such as bubble wrap or foam, to protect it from scratches and impact during transit.

- Place the charger in a sturdy box: The wrapped charger should then be placed in a sturdy box that is appropriate for the size and weight of the EV Charger . The box should be made of durable material, such as corrugated cardboard or plywood, and should be able to withstand the rigors of sea transit.

- Add packing material: The box should be filled with packing material, such as packing peanuts or air pillows, to provide cushioning and prevent the EV Charger from shifting during transit.

- Seal the box: The box should be securely sealed with high-quality packing tape to prevent it from opening during transit.

- Label the box: The box should be clearly labeled with the charger’s name, weight, and any other relevant information, as well as the destination address and contact information.

Overall, the goal is to pack the small chargers in a way that will protect it from damage during transit and ensure that it arrives at its destination in good condition. It is important to follow proper packing procedures and use high-quality packing materials to minimize the risk of damage during sea shipment.

Large EV Charger Packing:

Packing a large EV Charger for sea shipment can be a complex and challenging task. However, with careful planning and attention to detail, it is possible to pack a large EV Charger for sea shipment in a way that will ensure that it arrives at its destination in good condition. Here are some general steps that a manufacturer may follow when packing up a large EV Charger for sea shipment:

- Clean and prepare the EV Charger : Before packing, the EV Charger should be thoroughly cleaned and prepared. All fluids, such as oil or coolant, should be drained, and any loose or detachable parts should be removed.

- Disassemble the EV Charger : If possible, the EV Charger should be disassembled into its component parts to reduce its overall size and make it easier to pack. Each part should be carefully labeled and numbered to ensure that it can be easily reassembled at the destination.

- Protect delicate parts: Delicate or fragile parts should be wrapped in protective material, such as bubble wrap or foam, to protect them from damage during transit.

- Build a custom crate: A custom crate should be built around the EV Charger to provide a secure and sturdy enclosure. The crate should be made of durable material, such as plywood, and should be designed to fit the machine snugly. The crate should also include braces or supports to prevent the EV Charger from shifting during transit.

- Add cushioning material: The crate should be filled with cushioning material, such as packing peanuts or air pillows, to provide extra protection and prevent the EV Charger from moving or shifting during transit.

- Securely fasten the EV Charger : The EV Charger should be securely fastened to the crate to prevent it from moving or shifting during transit. This may involve using straps, bolts, or other fasteners to hold the machine in place.

- Seal and label the crate: The crate should be securely sealed with high-quality packing tape, and should be clearly labeled with the EV Charger’s name, weight, and any other relevant information. The destination address and contact information should also be clearly marked on the crate.

Overall, packing a large EV Charger for sea shipment requires careful planning and attention to detail. It is important to use high-quality materials and follow proper packing procedures to ensure that the EV Charger arrives at its destination in good condition. A professional packing and shipping company may be consulted to ensure that the EV Charger is properly packed and prepared for sea shipment.

Related Products

Related Articles

Contact Us

Frequently Asked Questions (See More FAQ)

-

Are you a factory or trading company?

We are a professional manufacturer of new and sustainable energy applications for over 20 years.

-

What is the warranty?

Warranty period is 12 months. In this period, we will supply technical support and replace the new parts by free,customers are in charge of delivery.

-

What is the packing method?

Generally, we pack our goods in brown cartons. If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

-

What is your terms of payment?

T/T 50% as deposit, and 50% before delivery. We’ll show you the photos of the products and packages before you pay the balance.

-

What is your terms of trade?

EXW, FOB, CFR, CIF, DAP,DDU,DDP

-

How about your delivery time?

Generally, it will take 3 to 7 working days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

-

Can you produce according to the samples?

Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

-

What is your sample policy?

We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

-

Do you test all your goods before delivery?

Yes, we have 100% test before delivery.

-

Is a Tesla charging AC or DC?

Teslas are equipped with onboard chargers that can handle both AC (alternating current) and DC (direct current) charging.

When you charge a Tesla at home or at most public charging stations, you are using AC charging. The AC power is supplied to the Tesla’s onboard charger, which converts it to DC to charge the vehicle’s battery. This is the most common method of charging for electric vehicles, including Teslas.

However, Teslas also support DC fast charging, commonly referred to as Supercharging. Tesla Superchargers are high-power DC charging stations that can directly supply DC power to the Tesla’s battery without the need for the onboard charger to convert it. This allows for significantly faster charging times and is especially useful for long-distance travel or quick top-ups during road trips.

In summary, Teslas can charge using both AC and DC methods. AC charging is used for regular charging at home and most public charging stations, while DC charging (Supercharging) is used for faster charging at dedicated Tesla Supercharger stations. -

Is Type 2 charger AC or DC?

A Type 2 charger is an AC (alternating current) charger.

The Type 2 charger, also known as the Mennekes charger, is the most commonly used charger for electric vehicles in Europe and many other regions. It is designed to deliver alternating current (AC) power to the electric vehicle’s onboard charger.

When you plug your electric vehicle into a Type 2 charger, the AC power is transferred from the charging station to the vehicle’s onboard charger. The onboard charger then converts the AC power to DC (direct current) to charge the vehicle’s battery.

In summary, the Type 2 charger is an AC charger, which means it provides alternating current that is later converted to direct current by the vehicle’s onboard charger to charge the electric vehicle’s battery.