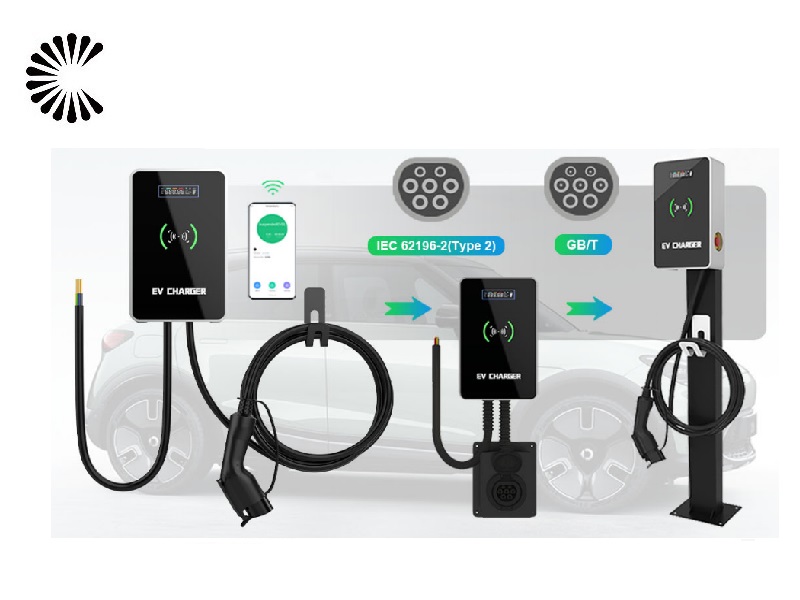

400V GB/T connectors EV Charger

home/business/station Highway gas, service station, Parking garage, home use, commercial use, EV infrastructure operations and service providers, EV dealer workshops

AC EV Charger

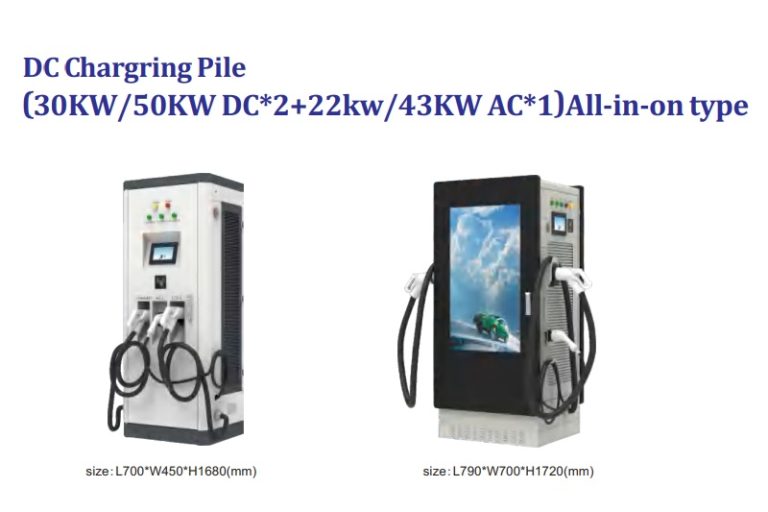

Parameters & Configurations:

Certification:

EU & US, with CE, UL Certification.

Parameters (Input, enviornmental, mechaical, output, Unser interface and display, communication, protection and safety Requirements)

| EV Charger Type | AC 32A (EU) |

| Product Model NO. | HK-CS-HKAC 32 (EU) |

| Input Rating | 230 Vac /Single Phase 400Vac/Three Phase |

| AC Input Connection | LN/PE3P/N/PE |

| Max. Input Current (A) | 32 |

| Frequency (Hz) | 45-65 |

| Residual Current Device(Type B Optional) | Type A:In 30 mA Type B:IAn 30 mA+ dc 6 mA |

| Display | 3.5 inch LCD |

| IP Level | IP54 |

| Regulation Certificate | IEC 61851-1:2017 IEC 61851-21-2 |

| Safety | CE |

| Charging interface | IEC 62196-2:2016,Type 2 Plug |

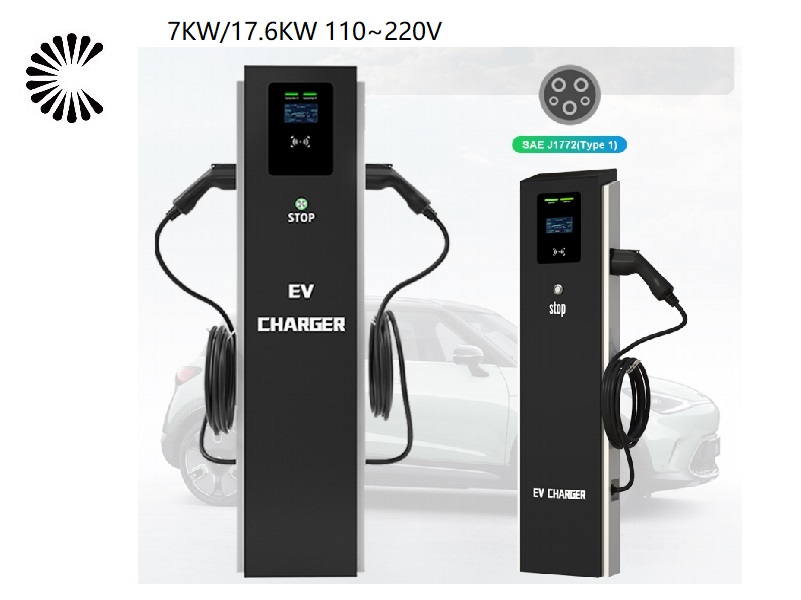

| EV Charger Type | AC 32A (US) |

| Product Model NO. | HK-CS-HKAC 32 (US) |

| Input Rating | 208-240 Vac/1-phase(AC Level 2) 400Vac/Three Phase |

| AC Input Connection | LN/PE3P/N/PE |

| Max. Input Current (A) | 32 |

| Frequency (Hz) | 45-65 |

| Residual Current Device(Type B Optional) | CCID 20 |

| Display | 3.5 inch LCD |

| IP Level | NEMA TYPE 3R |

| Regulation Certificate | UL2594UL2231-1/-2 |

| Safety | UL/cUL |

| Charging interface | SAEJ1772 Type 1 Piug |

User interface&Control

- Display: 3.5 inch LCD

- User Authentication: RFID ISO/IEC 14443A/B

- Display information Current, Energy

Communication

- Extemal : intemal OCPP 1.6 JSON

- Operating Temperature: (°c) -30~50

Environmental:

- Humidity (%) 5-95RH non-condensing

- Altitude(m): ≤2500m

- Cooling method Natural Cooling

Mechanical:

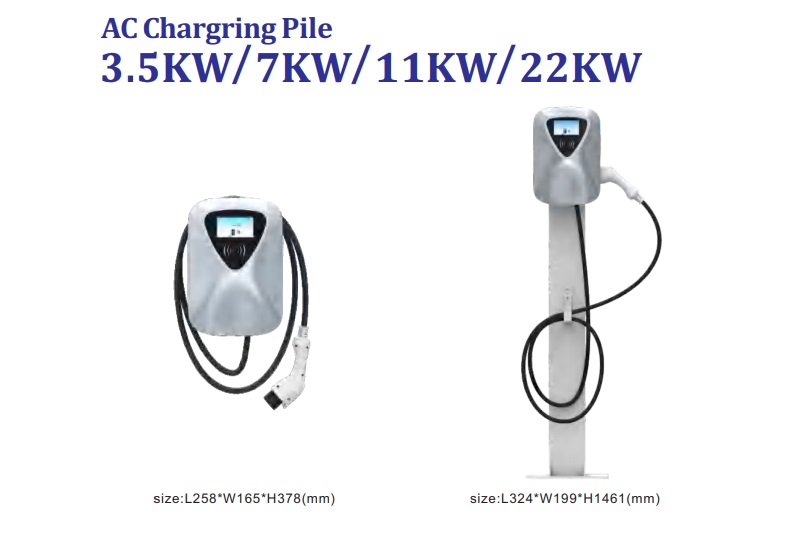

- Dimension(WxDxH mm): 160*280*398.5(Wall mounted type) 181.5*280*1515(Floor mounted type)

- Weight(kg): ≤14kg(Wall mounted type) ≤20kg(Floor mounted type)

- Cable Length(m): 5meters

Protection

- Input Protection: OCP:<352A/OVP;>275V/UVP:<160V Output Protection OCP<352A/OVP:>275V/UVP:<160V

- Ground Fault Protection: Lost input ground connection

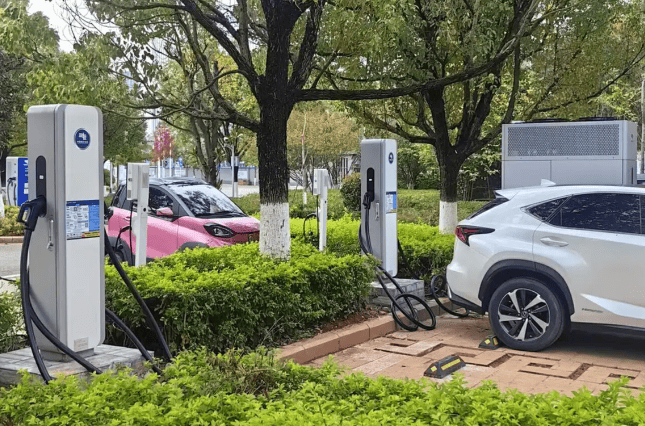

Showcase

Feature

- Ideal choice for following application such as residential, community, commercial usage and so on.

- Optional wired or wireless connection for management system of backside office choose;

- User can choose RFID Card reader for identification or management;

- Input Voltage Rage : 220Vac~240Vac/400Vac±15%;

- IP54 rated suitable both for indoor/outdoor environments;

- Firmware is able to update via remote connection ways;

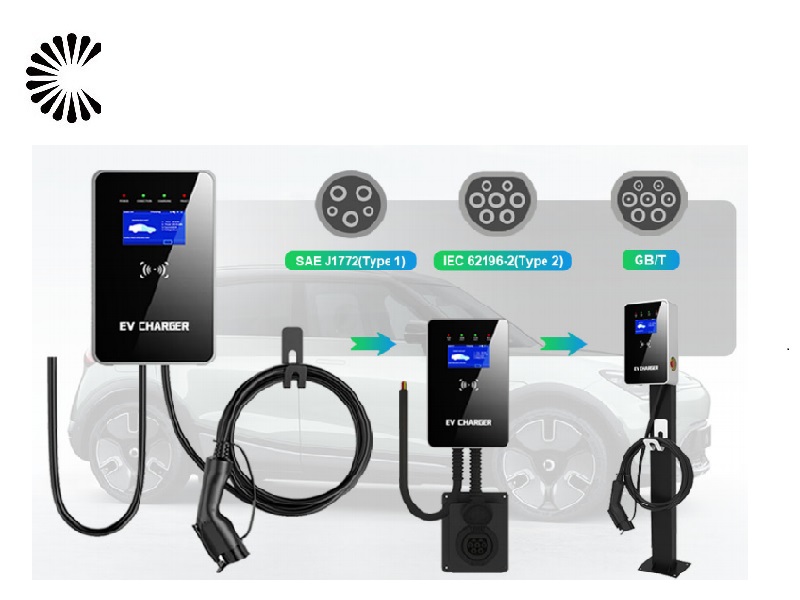

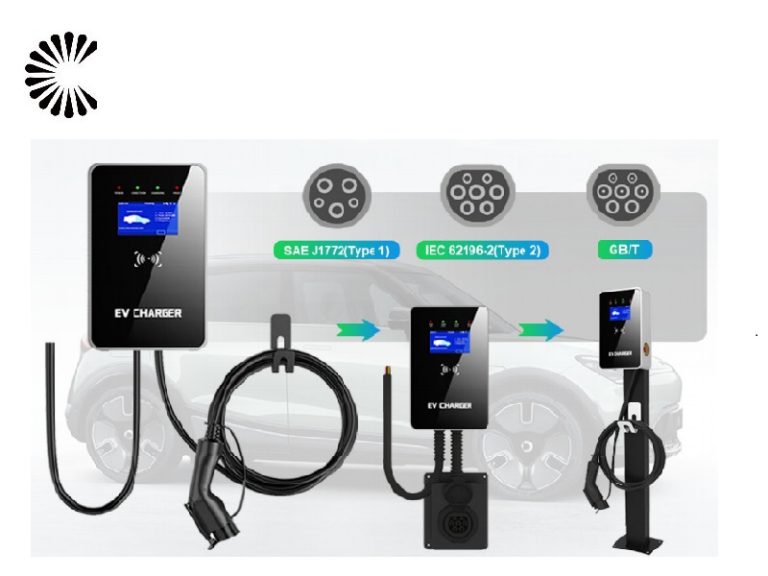

- Charging interface of two types: Tupe 1(SAE J1772)/ Type 2 (IEC 62196-2)

Application

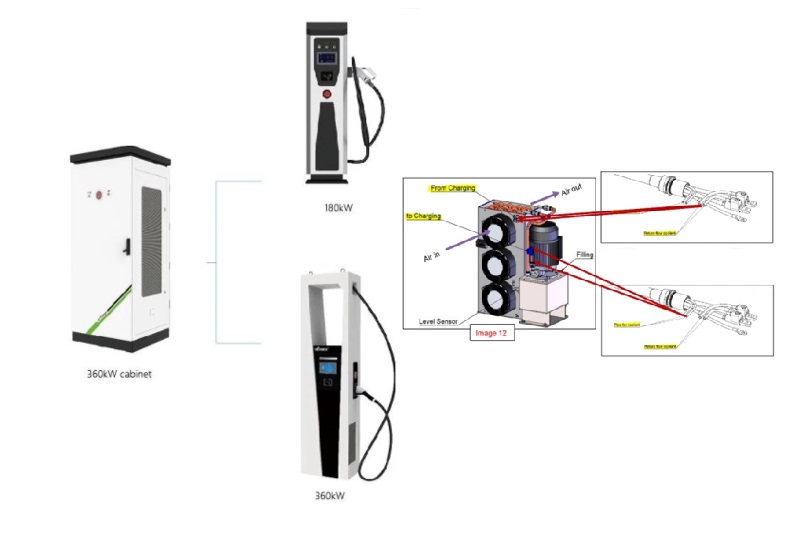

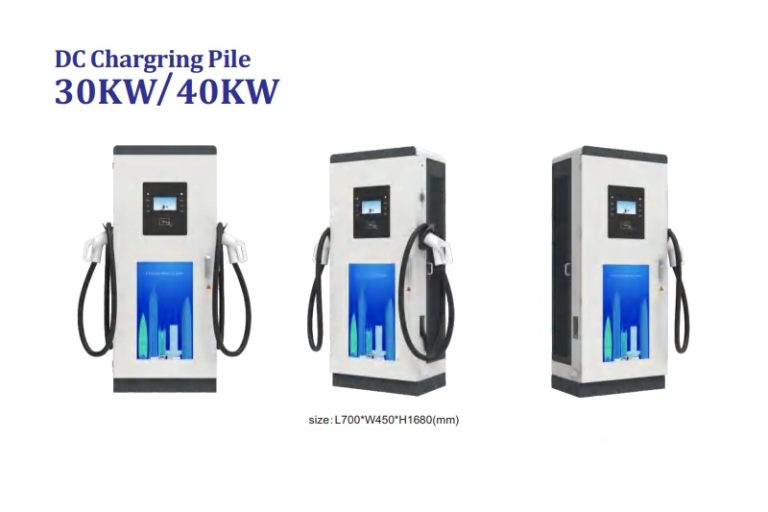

They are suitable for occasions such as city special charging stations that provide charging for

bus, taxi, public service vehicles, sanitation vehicles,logistics vehicles, etc.; city public charging

stations that provide charging for private cars, commuter, bus; intercity highway charging

stations and other occasions that need special DC fast charging. Highway gas, sevice station, Parking garage, home use, commercial use, EV infrastructure operations and service providers, EV dealer workshops.

Here we list down some of application scenarios:

1. Business organizations: Supermarket, Shopping mall, Hotel, Restaurant, Pharmacy

2.Non-profit organizations: Airport, Railway / bus station, Exhibition, Museum, Hospital, School, Convention center, Lottery station, Government affairs center

3.Financial organizations: Bank, Insurance company, Foundation, Security company

4.Entertainments: Movie theater, Club, Bar, Salon, Gambling house

Suitable for Car Brands:

Almost all the electric car, minibus, bus, van vehicles are suitable. Please contact with our sales team to confirm the right models.

KINGSTAR EV YUTONG EV BYD EV GEELY EV BENZ EV ZXAUTO DONGFENG MOTOR

Transportation

In the course of transportation, the charger should be packed firmly and intact in

a solid wooden packing box, and the direction of loading and unloading should be marked.

The charger should not be stored and transported upside down. In the course of

transportation, corresponding tightening measures should be taken to avoid strong

vibration and bump damage to the outer packaging of equipment. After arrival of the

goods, user should check whether there is any damage. If there is any transport damage,

user should consult with the transport party or our company to solve it. Check whether

the contents in the box are in conformity with the packing list immediately after

opening the box.

The packaged equipment should be stored in the room where the relative humidity is

less than 80% and the ambient air temperature is -20℃ to +55℃. Storage places should

be dry, clean and airy, and can prevent the invasion of harmful gases. It is strictly

forbidden to store corrosive articles in the same place.

Note: It is strictly forbidden for non-professionals to disassemble equipment

components.

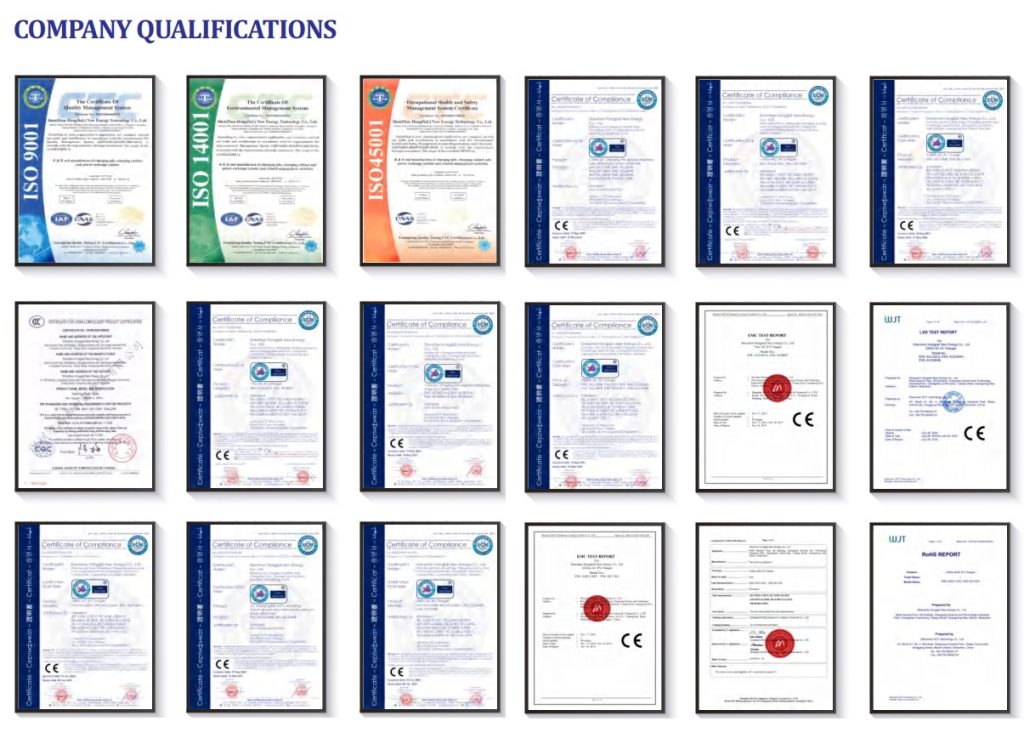

Certification

Our Factory have certifications such as CE ISO Certifications. TUV /UL /CE Certificated for Overseas on cable and wire.

Why choose us

- Decades of Experiences: As a Chinese academy of sciences park high-tech enterprise and manufactory, our factory establised since 2002, with over 10 years factory development, our factory became famous brand in China. We believe new energy is the future, better to environment and more economical to our life. We are an integrated hi -tech electronic company. “Passion, Honesty, Sound service, Keen cooperation and Development” are our goals. We are here expecting friends all over the world!

- Various Charging Products: Full range of charging products as well as charger accessories. Provide full support to customer after-sale services. Most of the model of produts are able to be customized.

- For all the products that we shipped have 1 year warranty period as well as life time spare parts and accessories with competitive price .

- Accept customized OEM ODM products.

- Experienced foreign trade team to handle the shipment and after-sale services.

- Efficient and fast supply chain.

Maintenance

- Charger body is easy to be fixed with anchor bolts to prevent it from inclining

and dithering due to external and human factors. - Shading and rainproof measures should be taken for chargers. It is suggested

to install shelters outdoors. - Check regularly whether all bolts in chargers are tightened, whether the connecting wires are loosened or not, or the connection is not firm, etc.

- Check for short circuit.

- Check whether the emergency stop button is available.

- Attention should be paid to lightning protection to ensure effective shielding

and reliable grounding of chargers. - When in use, the output voltage and current of the charger should be controlled within the nominal range to ensure that the charger works in the state of maximum efficiency.

- When the charger stops using, the charging output should be stopped first, then the cable should be wrapped and put back in place.

Note: During the transportation, the chargers should be packed firmly and the

direction of loading and unloading should be marked. It is forbidden to store and

transport chargers upside down. Corresponding tightening measures should be taken

to avoid strong vibration and turbulence damage to the outer packaging of equipment.

Factory Introduction

As long as the Global urban populations are expanding. As reported, it‘s estimated that in 2050, 66% of the global population will be in cities. In order to reduce the growing problem of traffic congestion, governments of various countries are working with car manufacturers to implement smart services and ride-sharing by encouraging the use of electric vehicles. Through Intelligent’s renowned and advanced technology , our factory has successfully developed a series of highly efficient EV charging solutions. We began to do efforts on EV systems and chargers since 2015. The factory become the charger supplier for several Chinese large electric buses. We has also earned the acclaim of the cooperated car manufacturers and operators. Moreover we working with several EV operators in Europe and Southeast Asia. We have been always committed to the healthy development of green transportation and promotion of the new energy all over the world.

| Certificate: | CE RoHS FCC Certificate | Warranty: | 12 Months |

| Input Voltage: | 110V-380V | Output Voltage: | 0-750V |

| Working Temperature: | -25℃-55℃ | Application: | Home Use/Commercial Use |

| OEM Service: | Color,Logo,Package, cable length, cable color | Supply Ability : | 4000 Piece/Pieces per Week |

| Packaging & Delivery: | Shanghai Port | Capacity | 4000 Piece/Pieces per Week |

| Lead Time: | Quantity(units) 1 – 5 5 working days | Factory Type | Supplier |

| Country / Region | China/Gungdong | Main Products | EV Charging Station, EV Charging Cable, EV Charging Connector |

| Factory employees | Over 100 people | Total Annual Revenue | Above US$100 Million |

| Main Markets | Europe South America | Connection: | type 1 or 2 plug |

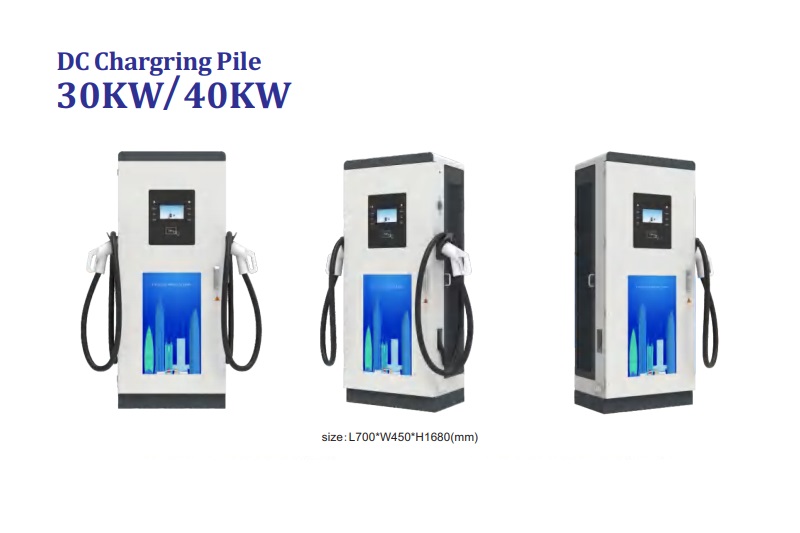

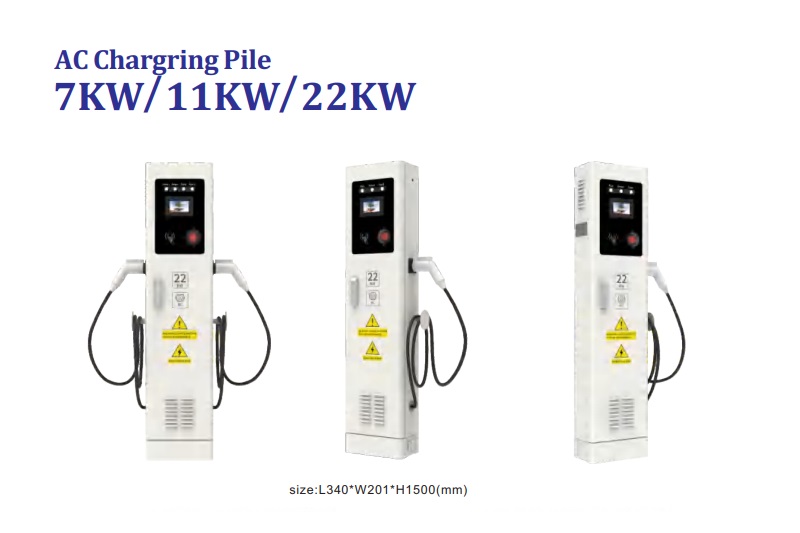

| Mass production price | Negotiable | Charger Capacity | 3.5kw~480kw |

| Current | DC/AC | Plug type | Type 1,2,CHAdemo/CCS-2/CCS-1 |

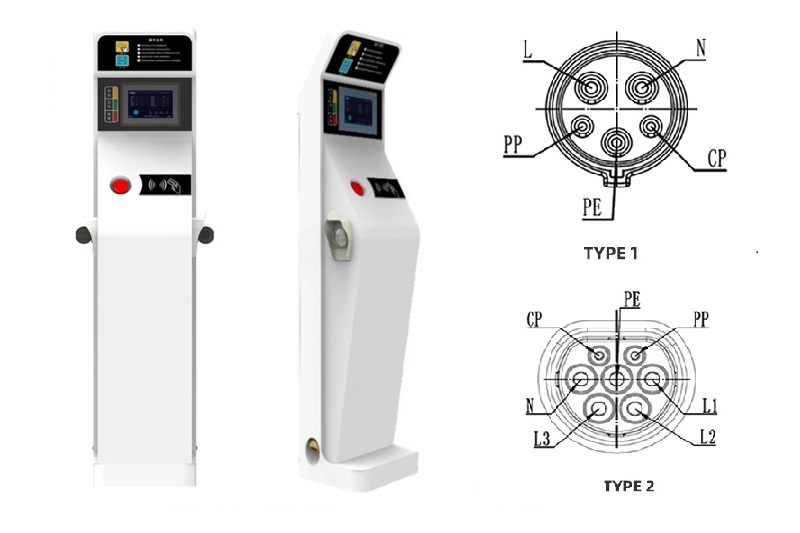

Different types of Charging pile interface commonly used in the world:

Charging pile charging interface standards are mainly as follows:

- European standard: Also known as Mennekes standard, is the charging interface standard used in most parts of Europe, suitable for AC charging and DC charging. It uses a 7-pin plug for high safety and compatibility.

- American standard: It is the charging interface standard used in North America and is suitable for AC charging. It uses a 5-pin plug for high safety and compatibility.

- Japanese standard: It is the DC charging interface standard used in Japan, which is suitable for DC fast charging. It uses a 9-pin plug for high charging power and compatibility.

- National standard standard: It is the charging interface standard used in China, suitable for AC charging and DC charging. It uses a 7-pin plug for high safety and compatibility.

In addition to the above main charging gun interface standards, there are some other regional or specific model used charging interface standards, such as the UK standard (Type 2), Tesla standard (Tesla Supercharger), and so on.

When choosing a charging pile, you need to determine the interface type of the charging pile according to your electric vehicle model and the charging standards in your region to ensure that the charging gun can be compatible with the charging pile.

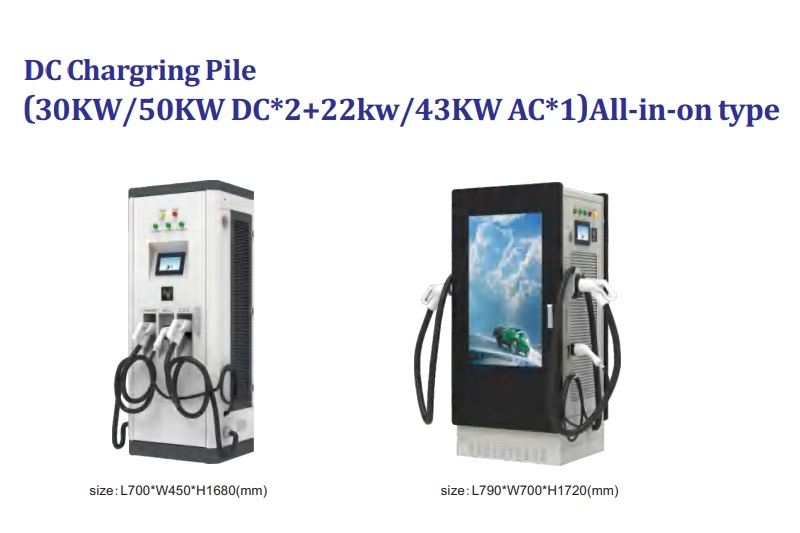

Simple analysis of AC charging pile interface and DC charging pile interface

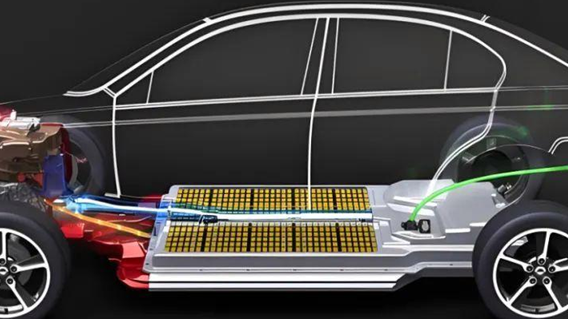

Compared with traditional oil vehicles, pure electric vehicles have many advantages, which are not listed here, but a troublesome place for pure electric vehicles is the need to consider the length of charging time and battery life. There are many compromises in the hybrid space, such as plug-in, extended-range, etc., which do not require a large battery capacity, reduce the waiting time for charging compared to pure electric vehicles (and increase the range by using gasoline/diesel).

In the field of pure electric vehicles, it is difficult to unilaterally optimize the charging time or battery life, fish and bear’s paw can not be both, because the life of the battery and the size of the charging rate, in general, the greater the charge and discharge rate, the smaller the number of cycles.

In order to ensure that the number of battery cycle charging can be between 800 and 1000, usually the charging rate should be between 0.5C and 0.25C, the national grid power supply, the use of vehicle charger to charge the power battery, which belongs to the slow charging scheme, the supporting public facilities are AC charging pile.

Ac charging pile interface

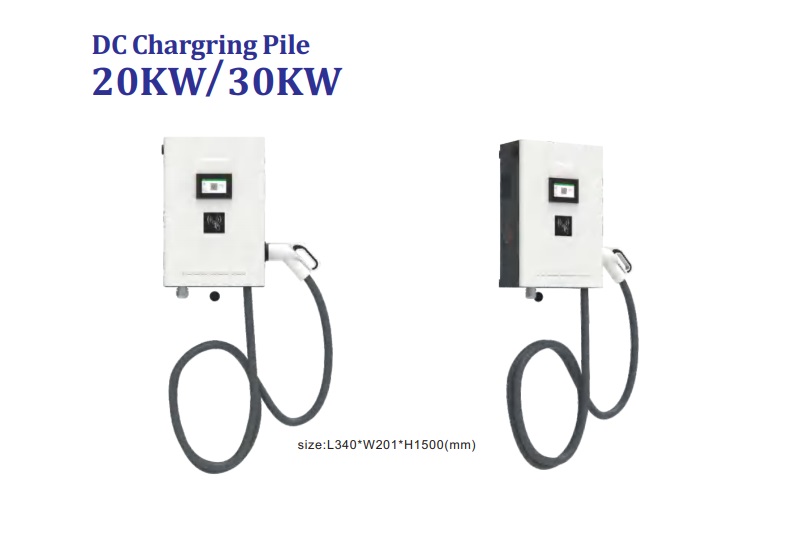

In order to cope with emergencies, it is hoped that the battery can be filled to 80% of the maximum capacity within 15 to 30 minutes, and the corresponding charging rate should be between 2C and 4C, which belongs to the fast charging scheme, and the supporting public facilities are DC charging piles. Dc charging pile damage to the battery is relatively large, the owner spent on the cost of replacing the battery will increase, so if not very urgent situation, should try to reduce the use of DC charging pile (free).

Dc charging pile interface

The principle of charging piles at home and abroad is much the same, but the shape is slightly different, as follows:

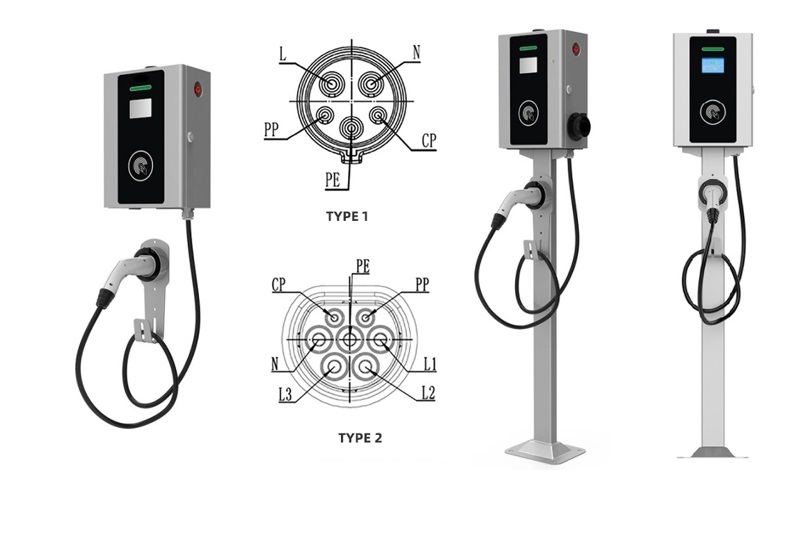

Second, explain the interface technology of AC charging pile

The AC charging pile charges the battery through the vehicle charger. Compared with the DC charging pile, the AC charging pile has low cost, simple structure, and is more friendly to the battery, which is suitable for popularization and promotion in a large area. Next, the interface technology of the AC charging pile will be introduced from the shallow to the deep.

The main function of AC charging pile (including national standard and non-national standard) is to draw out single-phase or three-phase electricity, charging pile only plays the role of current transfer station, and the subsequent rectification +DC/DC conversion is completed by the vehicle charger.

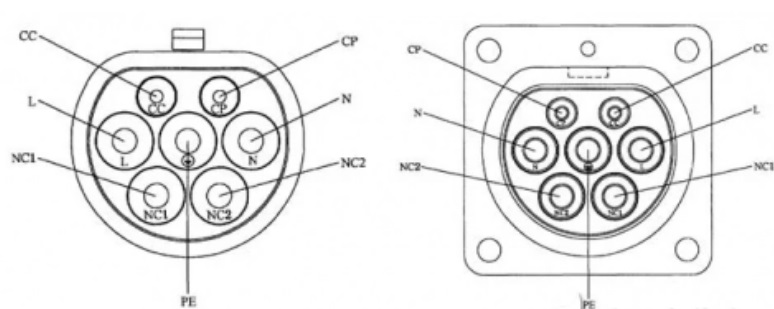

The national standard AC charging pile is based on the original AC charging pile shown in the figure above, adding some commercial modules (such as human-computer interaction interface, billing module, alarm module, etc.) and control and guidance circuit, which is the core content of AC charging pile interface technology. And in order to be compatible with single-phase and three-phase electricity, the national standard AC charging pile interface ultimately adopts a 7-terminal structure, and its terminal distribution is as shown in the following figure:

The main function of the control guidance circuit is to confirm whether the charging interface and the charging socket are connected, and then periodically detect during the charging process to determine whether to continue charging or stop charging.

The following details the working principle of the control guidance circuit:

- Confirm the connection

(1) The vehicle control device confirms whether the vehicle plug and the vehicle socket are connected by detecting the resistance value between the PE and the monitoring point 3;

(2) The power supply control device on the side of the charging pile determines whether the power supply plug and power socket are connected by detecting the voltage value of the monitoring point 4 or the detection point 1.

- Start charging

When both the vehicle interface and the power supply interface are confirmed to be connected, the charging pile switches the switch S1 from the 12V connection state to the PWM state, and waits for the vehicle control device to close the switch S2. At this time, the peak voltage of detection point 1 is 9V, and the PWM wave of 1KHz is generated at the CP end, whose duty cycle represents the rated current of the charging pile. When the vehicle side switch S2 is closed, it means that the vehicle is ready for charging. At this time, the voltage peak at detection point 1 is 6V. After confirming that the vehicle is ready, the charging pile closes the contactors K1 and K2 to make the AC circuit open and the charging starts. The voltage state of detection point 1 during the whole process is as follows:

- Cycle detection of charging process

During the charging process, the charging pile periodically detects the detection point to confirm the connection status of the charging connection device and whether the vehicle is in a rechargeable state, and the detection cycle is not more than 50ms.

(1) During the charging process, the charging control device continuously detects detection point 4 and detection point 1. If the power supply interface is detected to be disconnected, the switch S1 of the power supply control device switches to 12V and disconnects the AC power supply loop;

(2) In the charging process, the vehicle control device continuously detects detection point 2 and detection point 3. If it is judged that the vehicle interface is disconnected, the vehicle control device controls the vehicle charger to stop charging and disconnect the switch S2.

- End of charging

As mentioned above, the control guidance circuit is the soul of charging pile interface technology, which is crucial for electric vehicle designers and users.

Other GB/T connector EV Charger:

400V GB/T connectors EV Charger Wholesale Manufacturer In China

400V GB/T connectors EV Charger is suitable for both home and commercial outdoor use. We are wholesale manufacturer for 32A EV Charger, Once you have selected the right models, place your wholesale order for the 32A EV chargers.

Related Products

Related Articles

Contact Us

Frequently Asked Questions (See More FAQ)

-

Are you a factory or trading company?

We are a professional manufacturer of new and sustainable energy applications for over 20 years.

-

What is the warranty?

Warranty period is 12 months. In this period, we will supply technical support and replace the new parts by free,customers are in charge of delivery.

-

What is the packing method?

Generally, we pack our goods in brown cartons. If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

-

What is your terms of payment?

T/T 50% as deposit, and 50% before delivery. We’ll show you the photos of the products and packages before you pay the balance.

-

What is your terms of trade?

EXW, FOB, CFR, CIF, DAP,DDU,DDP

-

How about your delivery time?

Generally, it will take 3 to 7 working days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

-

Can you produce according to the samples?

Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

-

What is your sample policy?

We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

-

Do you test all your goods before delivery?

Yes, we have 100% test before delivery.

-

How fast does a 32 amp EV charger charge?

The charging speed of a 32 amp EV charger depends on the battery capacity of the electric vehicle (EV) you are charging. To calculate the charging rate, you can use the formula:

Charging Speed (in kilowatts) = Voltage (in volts) x Current (in amperes)

Most electric vehicles have a battery voltage of around 400 volts. So, for a 32 amp EV charger:

Charging Speed = 400 volts x 32 amperes = 12,800 watts or 12.8 kilowatts

Keep in mind that this is the theoretical maximum charging rate. In practice, charging speeds can vary due to factors like battery temperature, battery state of charge, and other charging protocols.

As an example, let’s consider a hypothetical EV with a battery capacity of 60 kilowatt-hours (kWh). To estimate the charging time, you can use the following formula:

Charging Time (in hours) = Battery Capacity (in kWh) / Charging Speed (in kilowatts)

Using the values we calculated earlier:

Charging Time = 60 kWh / 12.8 kW ≈ 4.69 hours

So, with a 32 amp EV charger, it would take approximately 4.69 hours to charge the hypothetical EV from 0% to 100%.

Keep in mind that different EV models may have different charging efficiencies and charging speeds may vary slightly in practice. Nonetheless, a 32 amp EV charger provides a faster charging rate compared to lower amp chargers, helping you reduce the time spent charging your electric vehicle. -

Can I charge my EV with a 30 amp?

Yes, you can charge your electric vehicle (EV) with a 30 amp charger. Many EVs are designed to be compatible with a range of charging capacities, including 30 amp chargers.

The charging capacity of an EV charger is usually indicated in amperes (amps). A 30 amp charger provides a charging speed that is slightly slower than a 32 amp charger, but it is still capable of efficiently charging your electric vehicle.

When using a 30 amp charger, the charging speed will depend on your EV’s battery capacity and the specific charger you are using. As long as your EV is compatible with the 30 amp charger, you can safely and effectively charge your vehicle.

It’s essential to check your EV’s manual or manufacturer’s guidelines to ensure that it can handle a 30 amp charging rate. Additionally, make sure that the electrical circuit you are using to power the charger is appropriately rated for 30 amps to ensure safe and reliable charging.

Using a 30 amp charger is a convenient and viable option for charging your electric vehicle, and it provides a good balance between charging speed and electrical capacity. -

What cable for 32 amp EV charger?

For a 32 amp EV charger, you will need a suitable charging cable that can handle the higher amperage safely and effectively. The most common type of cable used for 32 amp charging is a Type 2 cable.

Type 2 cables, also known as Mennekes connectors, are widely used in Europe and many other regions for electric vehicle charging. They are designed to handle higher amperage levels, making them suitable for charging stations with a 32 amp capacity. These cables have a robust construction and are designed to ensure a secure connection between the EV and the charging station.

When purchasing a Type 2 cable for your 32 amp EV charger, it’s important to ensure that the cable is rated for the correct amperage and that it is compatible with your specific electric vehicle. Some EVs might require specific charging cable configurations, so it’s best to check your vehicle’s manual or contact the manufacturer for guidance.

Additionally, consider the cable length, as it can vary depending on your charging setup and parking location. Opt for a cable length that allows you to comfortably connect your EV to the charging station without unnecessary tension or strain on the cable.

Using the right Type 2 cable for your 32 amp EV charger ensures a safe and efficient charging experience, making sure your electric vehicle stays charged and ready for your journeys. -

How many kW is a 32A charger?

To calculate the kilowatt (kW) rating of a charger, you can use the following formula:

Charging Speed (in kilowatts) = Voltage (in volts) x Current (in amperes)

For a 32 amp charger, the charging speed would depend on the voltage used by the charger or your electric vehicle (EV). In most cases, EV chargers use a voltage of around 400 volts, which is common for many electric vehicles.

Using 400 volts as the voltage:

Charging Speed = 400 volts x 32 amperes = 12,800 watts or 12.8 kilowatts

So, a 32 amp charger has a rating of approximately 12.8 kilowatts, assuming it operates at 400 volts.

This means that the charger can deliver up to 12.8 kilowatts of power to your electric vehicle, allowing for relatively fast charging compared to lower amp chargers. However, the actual charging speed may vary depending on your EV’s battery capacity, state of charge, and other factors that can affect the charging process. -

How many kW is A 30 amp EV charger?

To calculate the kilowatt (kW) rating of a 30 amp EV charger, we will again use the formula:

Charging Speed (in kilowatts) = Voltage (in volts) x Current (in amperes)

For most electric vehicle (EV) chargers, the voltage used is around 400 volts, which is common for many EVs.

Using 400 volts as the voltage:

Charging Speed = 400 volts x 30 amperes = 12,000 watts or 12 kilowatts

So, a 30 amp EV charger has a rating of approximately 12 kilowatts, assuming it operates at 400 volts.

This means that the 30 amp charger can deliver up to 12 kilowatts of power to your electric vehicle, allowing for relatively fast charging compared to lower amp chargers. However, as with any charger, the actual charging speed may vary depending on your EV’s battery capacity, state of charge, and other factors affecting the charging process. -

Can you use A 30 amp to charge A Tesla?

Yes, you can use a 30 amp charger to charge a Tesla, but it will depend on the specific Tesla model and its charging capabilities.

Tesla electric vehicles typically come with an onboard charger that can handle different charging rates. Most Tesla models come with a built-in charger that can handle higher amperage levels, including 30 amps. However, some older Tesla models may have a lower charging capacity.

Newer Tesla models, such as the Model S, Model 3, Model X, and Model Y, are equipped with chargers that can handle higher amperage levels, making them compatible with 30 amp chargers. These models are designed to take advantage of faster charging speeds to reduce charging times.

If you have a Tesla vehicle with a higher-capacity charger, using a 30 amp charger can efficiently charge your vehicle, though the charging speed may not be as fast as using a higher amp charger.

However, it’s essential to check your Tesla vehicle’s manual or consult with Tesla’s official documentation to confirm the specific charging capabilities and requirements for your particular model. This way, you can ensure that you are using the correct charger and getting the most efficient and reliable charging experience for your Tesla. -

The types of ev charger connectors:

Charging pile interface commonly used in the world

Charging pile charging interface standards are mainly as follows:

European standard: Also known as Mennekes standard, is the charging interface standard used in most parts of Europe, suitable for AC charging and DC charging. It uses a 7-pin plug for high safety and compatibility.

American standard: It is the charging interface standard used in North America and is suitable for AC charging. It uses a 5-pin plug for high safety and compatibility.

Japanese standard: It is the DC charging interface standard used in Japan, which is suitable for DC fast charging. It uses a 9-pin plug for high charging power and compatibility.

National standard standard: It is the charging interface standard used in China, suitable for AC charging and DC charging. It uses a 7-pin plug for high safety and compatibility.

In addition to the above main charging gun interface standards, there are some other regional or specific model used charging interface standards, such as the UK standard (Type 2), Tesla standard (Tesla Supercharger), and so on.

When choosing a charging pile, you need to determine the interface type of the charging pile according to your electric vehicle model and the charging standards in your region to ensure that the charging gun can be compatible with the charging pile.