Can a normalelectrician fit an EVcharger?

Can a Normal Electrician Fit an EV Charger?

Yes, a regular electrician can potentially install a basic home EV charger, but this depends heavily on the charger’s power level, the complexity of the installation, and the electrician’s specific qualifications and experience. The fundamental idea is that, although a skilled electrician with the appropriate training may be able to handle easier configurations, a safe, dependable, and legal EV charging installation necessitates substantial technical expertise, adherence to stringent safety regulations, and frequently formal certification. It’s frequently not enough to just have general electrical skills.

The Crucial Role of Qualifications and Knowledge

A fundamental grasp of electrical circuits and practical skills is the absolute minimum starting point. The particular installation guidelines pertaining to EV supply equipment (EVSE) must be well understood by the electrician. This includes frequently manufacturer-specific instructions as well as national electrical codes (such as the NEC in the US) or comparable local regulations. Importantly, the installation strongly moves from a “maybe” to a “should be done by a specialist” if it entails changing the main electrical panel in the house, improving the service, or adding higher-power chargers (usually above 7kW). Beyond the usual scope of changing an outlet or installing a light fixture, these tasks require a deeper understanding of load calculations, potential effects on the entire home electrical system, and sophisticated safety protocols. An electrician lacking this specific expertise risks creating overloaded circuits, poor connections, or inadequate grounding – all significant fire or electrocution hazards.

Non-Negotiable Installation Requirements: Safety First

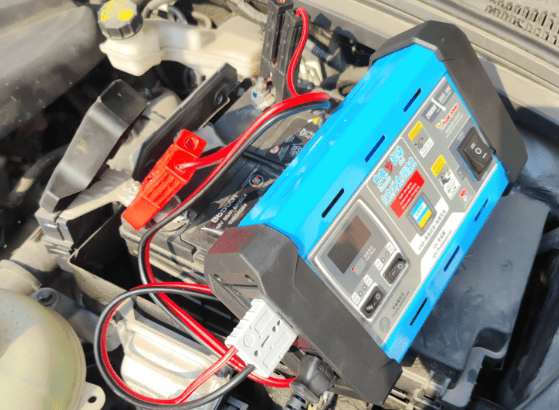

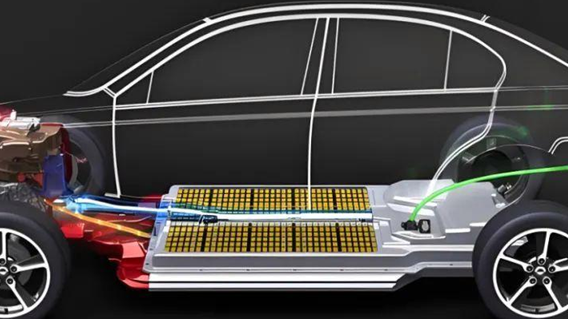

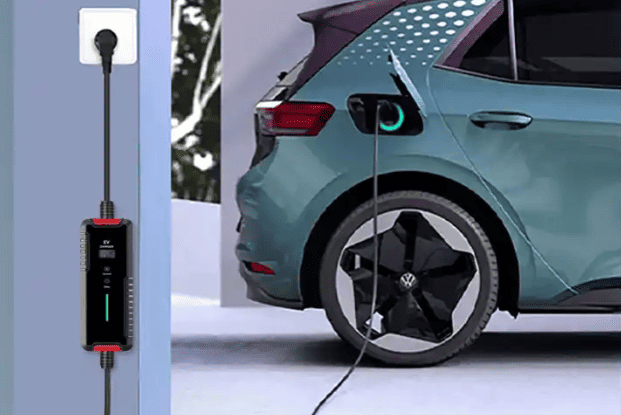

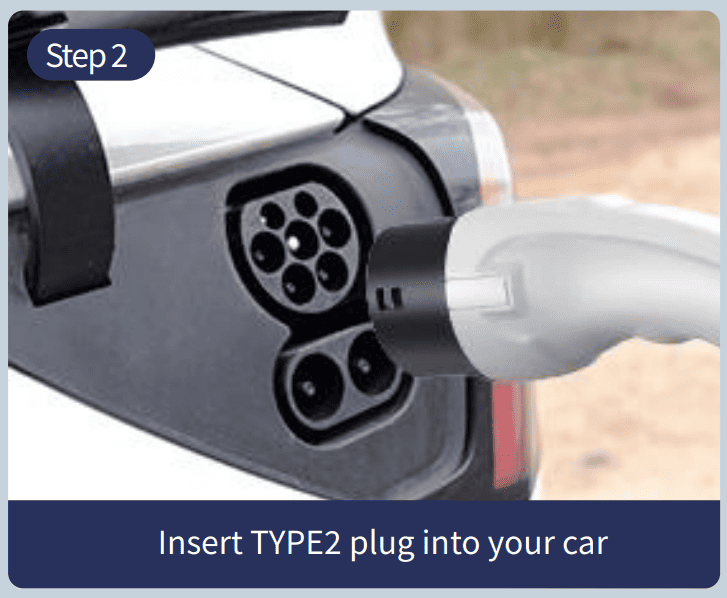

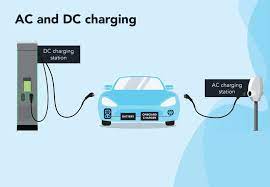

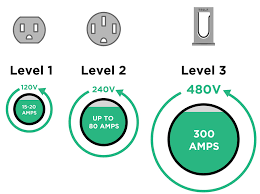

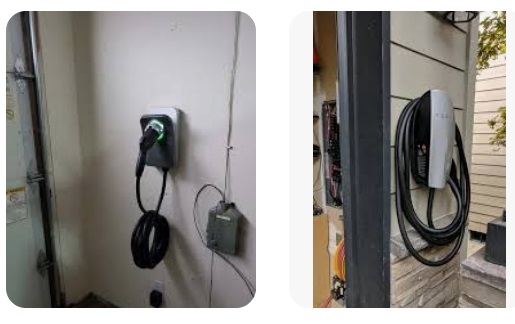

Power Compatibility is Paramount:A typical 220-240V AC single-phase supply powers the majority of entry-level home EV chargers. But a dedicated circuit is the most important prerequisite. This keeps other appliances from overloading the circuit, which only powers the EV charger. A properly sized circuit breaker (e.g., 40A for a 32A continuous load charger) must be used to protect the circuit. Importantly, a strong and properly installed grounding (earthing) system is essential for user safety and prevents electric shock in the event that the charger or the car malfunctions. It is very dangerous to have a bad or nonexistent ground connection.

Circuit Safety Demands Robust Components: The electrical wiring must be appropriately sized to carry the continuous high current an EV charger draws for hours without overheating. For a standard 7kW (32A) charger, this typically requires a minimum of 6mm² (roughly equivalent to 10 AWG) copper wiring. Using undersized wire (like common 2.5mm² lighting cable) is a major fire risk due to overheating under sustained load. The dedicated circuit breaker is essential to cut power instantly in case of an overload or short circuit. Furthermore, installing a Residual Current Device (RCD), also known as a Ground Fault Circuit Interrupter (GFCI), specifically rated for EV charging (often Type A or Type B depending on regional standards), is critical. This device detects tiny current leaks (potentially flowing through a person) and shuts off power within milliseconds, preventing fatal electric shocks. Ignoring these component specifications creates severe hazards.

Environmental Protection is Essential: EV chargers are constantly exposed, particularly those installed outside. An appropriate Ingress Protection (IP) rating (such as IP54 or IP65), which denotes resistance to dust and water infiltration, must be present on the charger unit itself. Both the charging cable and the supply cabling need to be specially rated for outdoor use. This entails being “Low Smoke Zero Halogen” (LSZH) or equivalent, which is essential for reducing toxic smoke in the event of a fire, and resistant to moisture, temperature extremes, and UV radiation (which prevents insulation degradation). Standard indoor cable deteriorates quickly outside and increases the risk of short circuits and insulation failure.

Critical Usage Precautions for End-Users

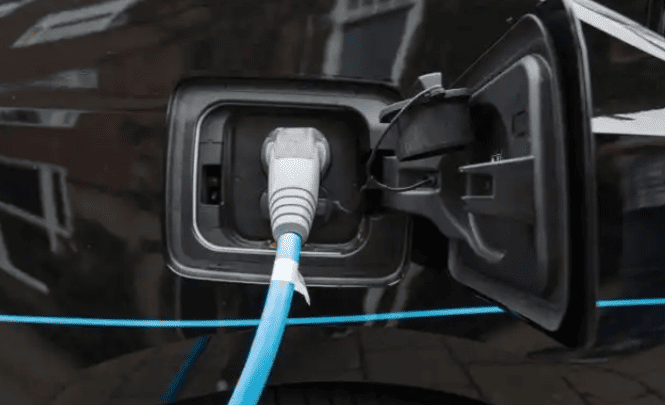

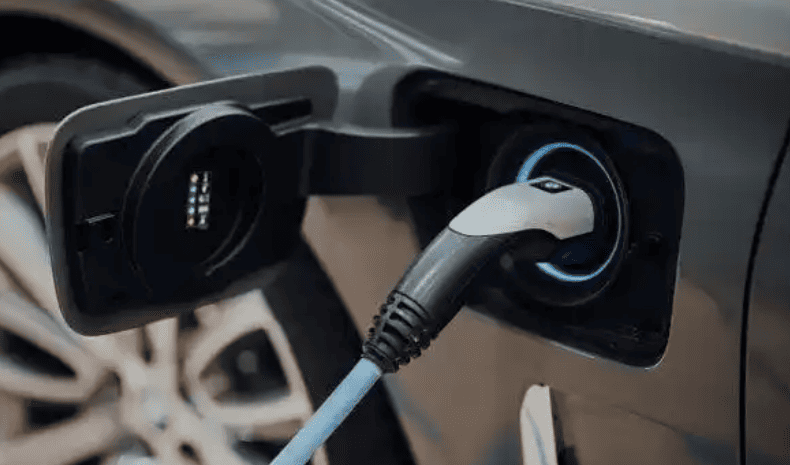

Beyond installation, safe operation relies on user awareness. Charging should never be attempted outdoors during rain or snow without adequate protection for the charger connection point and the vehicle’s charging port, as water can cause short circuits or electric shock. Users must avoid touching the charging connector pins, cable terminations, or the socket outlet while charging is active, as high voltage is present. Regular visual inspections are vital: Users should check the charging cable for damage (cuts, abrasion, cracking) and ensure the connector plugs securely and firmly into both the vehicle and the charger unit monthly. Loose connections can overheat, causing melting or fire.

If the electrician lacks demonstrable, specific experience with EV charger installations, it is strongly advisable to contact the vehicle manufacturer’s recommended service network or a specialist EV charging installation company. These entities employ technicians trained on the specific hardware and the unique safety protocols involved.

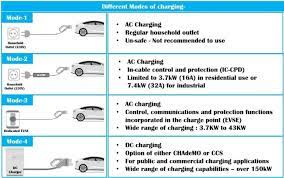

A Deeper Analysis: It Depends on the Charger Type

- Low-Power Home Chargers (e.g., 7kW AC or Less): Potential for Experienced Electricians

These are the most common home units, plugging into a 220-240V single-phase supply. The technical demands primarily involve robust circuit installation: correct wire sizing (6mm² copper for 32A), a dedicated and appropriately rated circuit breaker (e.g., 40A), a high-sensitivity RCD/GFCI, and impeccable grounding. An electrician with solid experience installing other high-demand appliances like electric ovens, cooktops, or large air conditioners (which also require dedicated circuits, heavy wiring, and careful load management) might possess the necessary foundational skills. They must understand continuous load calculations (EVs charge for hours, unlike a kettle’s brief peak), the critical importance of correct torque on terminal connections (loose connections arc and overheat), and verifying low ground resistance (≤4Ω). The installation process involves confirming sufficient spare capacity at the main electrical panel (often requiring a 60-100A main service), running the appropriately sized cable in safe routes (conduit if needed), mounting the charger securely, making all connections meticulously, and performing thorough functional and safety tests (including RCD/GFCI trip testing). While the concepts are familiar to experienced domestic electricians, the specifics of EV standards and the consequences of error are heightened. Lack of familiarity with nuances like PEN fault detection (in some systems) or specific communication protocols can lead to non-compliant or unsafe installations, even if the unit appears to work initially. - Higher-Power Chargers (11kW+ AC, DC Fast Chargers): Beyond a Normal Electrician’s Scope

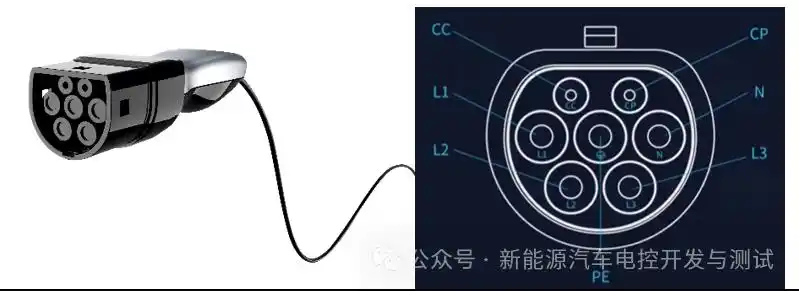

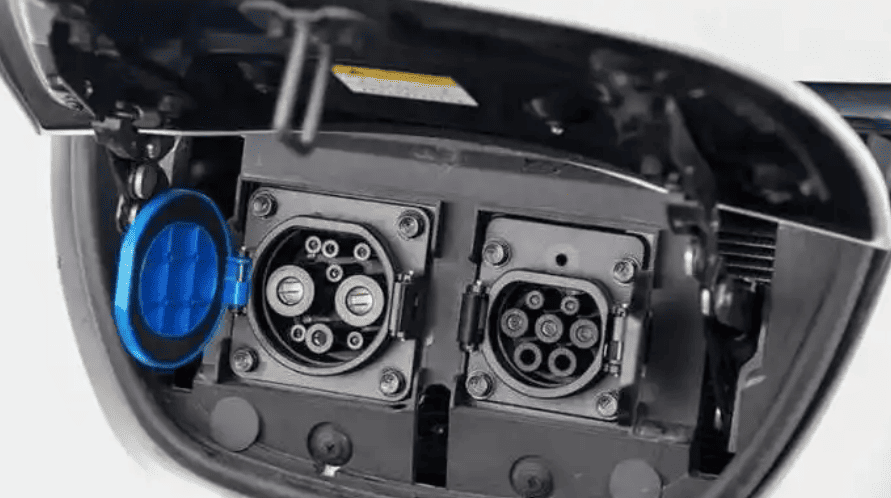

- 11kW+ AC Chargers: These typically require a 380-400V three-phase power supply. Working with three-phase power introduces significant complexity. The electrician must understand phase balancing (ensuring load is distributed evenly across all three phases to avoid transformer overload and voltage fluctuations), correct identification and connection of all live phases (L1, L2, L3), the neutral (N), and protective earth (PE). Mistakes here can lead to immediate equipment destruction, severe electrical faults, or dangerous voltage imbalances. Most general domestic electricians rarely encounter three-phase installations outside of commercial settings and lack the specific training and experience for safe EV charger integration on these systems.

- DC Fast Chargers (50kW+): These are complex power conversion units, not simple plugs. Installation involves handling very high voltages (often 480V AC input or higher) and currents. It requires integrating specialized switchgear, potentially complex grid connections (sometimes needing utility approval/coordination), managing significant heat dissipation (requiring proper ventilation or cooling systems), and ensuring correct communication between the charger, the vehicle’s Battery Management System (BMS), and potentially a network backend. This involves both high-voltage (“strong current”) and low-voltage control/data (“weak current”) systems. Installation demands specialized training, specific high-voltage safety certifications, and often formal licensing for electrical work at this scale (like a “Power Facility Installation License”). This is firmly in the realm of specialized electrical engineers and certified technicians, far beyond a typical residential electrician’s capabilities.

The Critical Constraints: Certification and Regulatory Awareness

- Formal Qualifications and Licensing: Regulations vary by region, but installing permanent EV charging infrastructure often legally requires electricians or companies holding specific licenses beyond a standard electrical contractor license. In many jurisdictions, connecting equipment to the public grid (even via a home meter) or performing significant panel upgrades necessitates certification demonstrating competency in these specific areas. A general electrician without this specific accreditation may be legally prohibited from performing the work, regardless of perceived skill. Property managers and utility companies will often require proof of such qualifications before approving the installation or granting connection.

- Deep Understanding of EV-Specific Safety Standards: EV charging introduces unique risks and corresponding safety standards. Installers must be intimately familiar with requirements like specific IP ratings for outdoor units, mechanical protection for cables, thermal management considerations, the design of charging connectors to prevent accidental contact with live parts (including specific pin shielding sequences), and comprehensive system testing protocols that go beyond basic circuit verification. This includes testing the interaction of the RCD/GFCI with the charger and vehicle, verifying correct communication for safe charge initiation and termination, and ensuring fault conditions are handled safely. A general electrician unfamiliar with these specific standards might overlook critical details – like using an RCD type incompatible with EV chargers, failing to secure cables properly against abrasion, or not performing all necessary post-installation functional safety checks – creating latent hazards.

- Warranty, Liability, and Professional Support: Using an uncertified or inexperienced installer often voids the charger manufacturer’s warranty. If a malfunction occurs – whether damaging the charger, the vehicle, or causing property damage/fire – the liability could fall entirely on the homeowner and the unqualified installer. Professional, certified installers provide documentation (certificates of compliance, test reports), typically offer their own workmanship warranty, and ensure the installation meets all regulatory requirements. This provides significant legal and financial protection. They also possess the diagnostic tools and manufacturer support channels to resolve complex issues.

Conclusion: Prudence Over Penny-Pinching

While a highly experienced and knowledgeable general electrician might technically install a basic 7kW (32A) single-phase home EV charger, provided they meticulously follow all codes, manufacturer instructions, and safety protocols (especially regarding wire gauge, dedicated circuits, RCD/GFCI selection, and grounding), it carries inherent risk. The nuances of EV charging standards and the critical importance of every safety detail mean that even minor oversights can have severe consequences. For any charger requiring three-phase power (typically 11kW and above) or DC fast charging, professional installation by certified EV charging specialists is absolutely mandatory due to the high voltages, complex systems, and specialized knowledge required.

Ultimately, prioritizing safety and compliance is paramount. Any perceived cost savings from hiring a less expensive, uncertified electrician are greatly outweighed by the risks of improper EV charger installation, which include electrical fires, electrocution, damage to pricey cars and property, void warranties, and denied insurance claims. Engaging a qualified EV charging installation specialist or an electrician with specific, proven accreditation in EVSE installation is the most safe and highly recommended course of action for peace of mind and assurance of safety. Specialized knowledge is required due to the intricacy and hazards present in EV charging infrastructure.