Charging Station Design

[ez-toc]

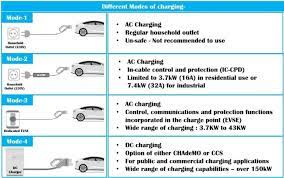

An “Charging Station Design,” as outlined in the IEC 61851-1 standard, refers to the fixed component of electric vehicle supply equipment that links to the power grid. This station can be affixed to a wall or positioned on the floor, and it operates with either AC or DC power. Its main purpose is to exclusively facilitate the charging of electric vehicles using Mode 3 (AC) and Mode 4 (DC) charging methods.

Subsequent sections offer comprehensive insights into the structure and distinctive features of EV charging stations operating in both Mode 3 and Mode 4

The Guideline for Charging the EV

When it comes to the design of charging stations, it’s crucial to adhere to the IEC 61851 standard. Charging stations operating in Mode 3 and Mode 4 must meet the requirements outlined in this standard.

The IEC 61851 standard encompasses a comprehensive set of guidelines. It covers various aspects, including mechanical construction, electrical components, communication protocols, electromagnetic compatibility (EMC), and overall performance criteria for electric vehicle supply equipment in both Mode 3 and Mode 4.

Part 1 of this standard lays down the fundamental prerequisites that serve as the basis for all subsequent standards within the series. It also details the specific requirements for AC charging stations. It’s worth noting that Edition 3 of this standard will become obligatory by February 2022 within the European Union.

Moving on to Part 21-2, this section focuses on the EMC requirements for off-board electric vehicle charging systems. It defines whether a charging station falls under the Class A or Class B category.

Class A off-board electric vehicle charging systems are designed for use in various locations except residential areas. Additionally, they are suitable for locations directly linked to low voltage power networks that supply buildings intended for non-residential purposes.

Conversely, Class B off-board electric vehicle charging systems are intended for use in residential settings as well as establishments connected to low voltage power networks that serve residential buildings.

Part 23 of the standard outlines the specifications for DC charging stations, whether they are permanently hardwired or plug-connected.

Part 24 is dedicated to the digital communication interface between a DC charging station and an electric vehicle. This feature enables control over the DC charging process.

In a broader context, the specific characteristics of a charging station are determined by its intended use and the location where it will be installed.

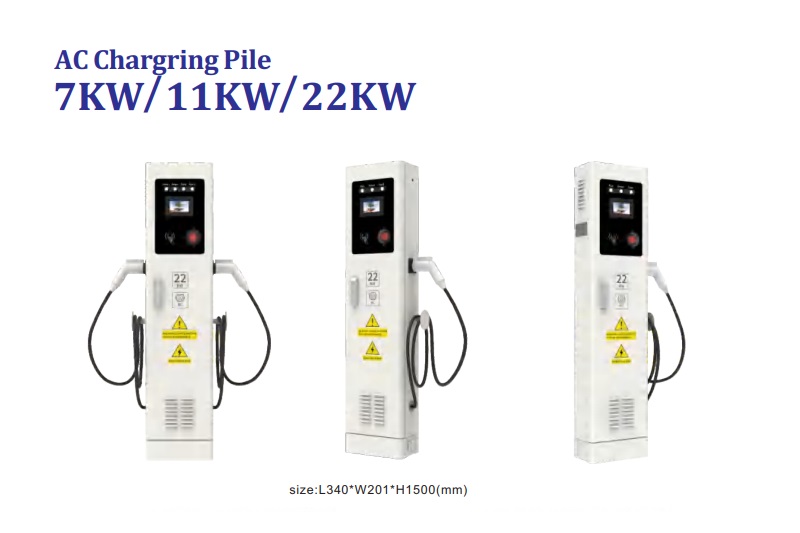

Power and Current Delivery for AC Charging

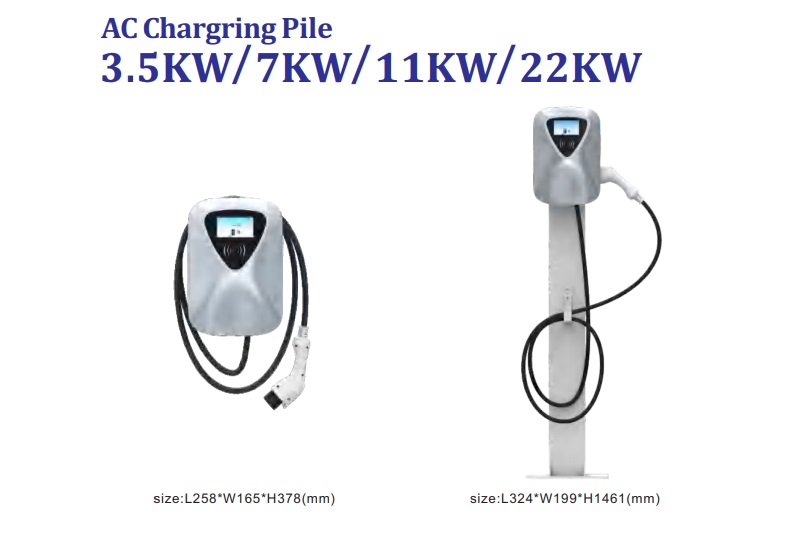

When it comes to Mode 3 charging station design, AC charging stations provide power options of 3.7 kW, 7.4 kW, 11 kW, or 22 kW. The standard maximum current these stations deliver is 32 A.

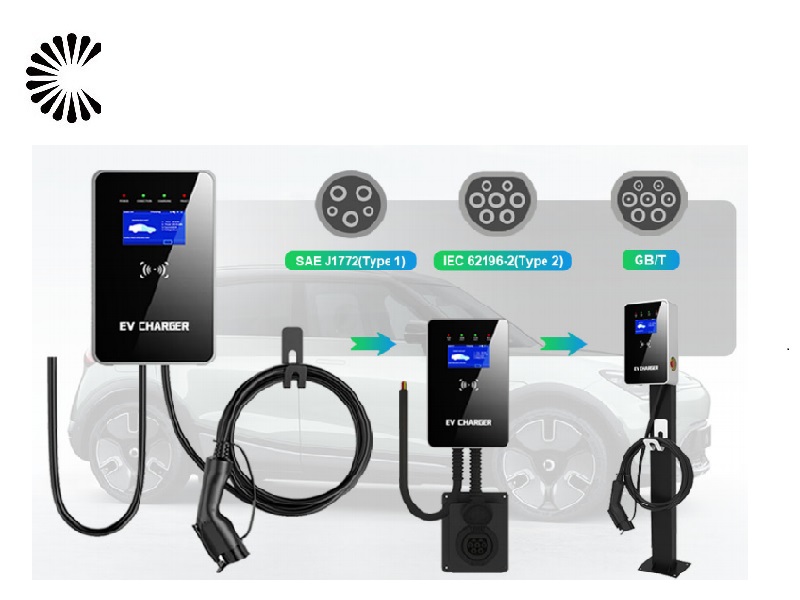

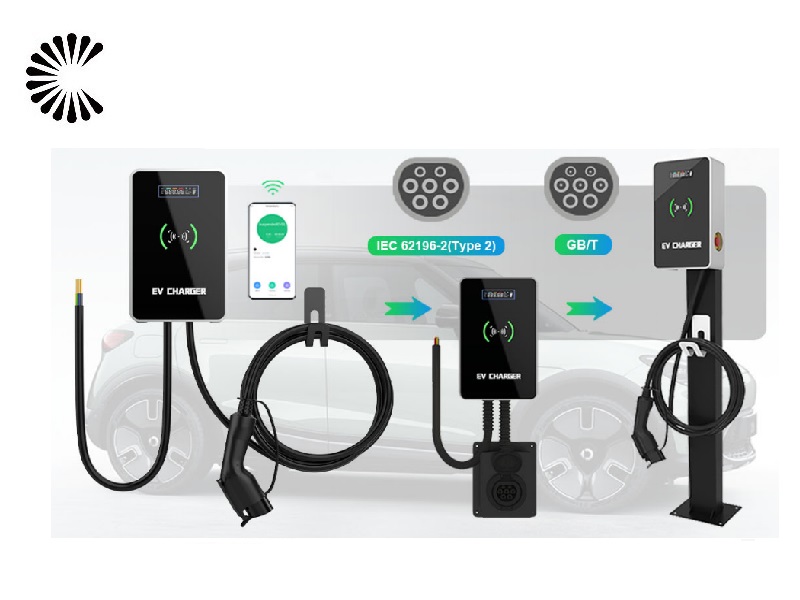

AC Charging Station Installation Types

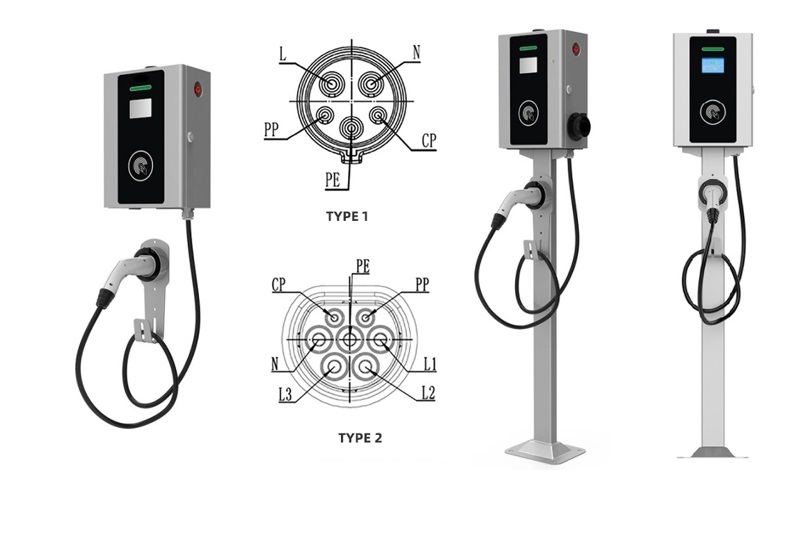

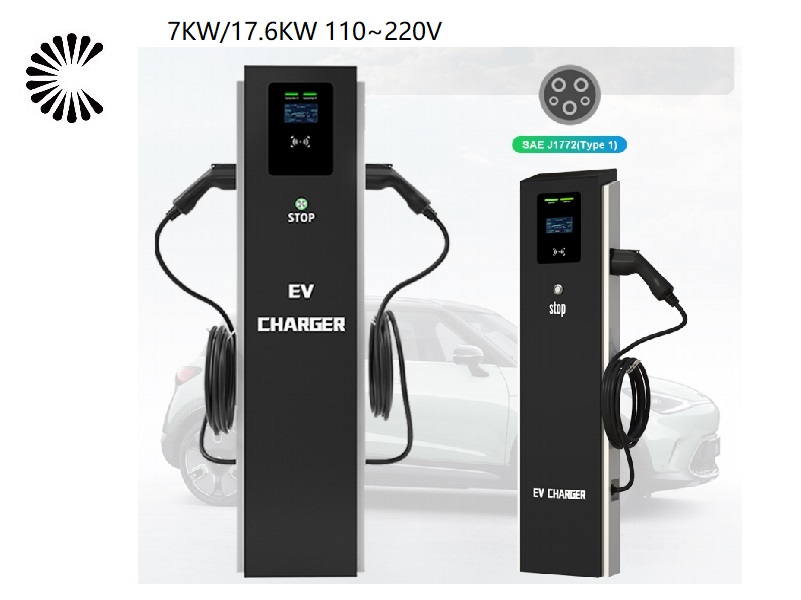

Fig. EV20 – Illustrations of Charging Stations. There are two primary installation options for AC charging stations: wall-mounted or floor-mounted.

Wall installations are particularly suitable for settings like single-family homes.

Floor installations utilize a pedestal to support one or several charging stations. The stations can even be incorporated within the pedestal. This setup is often employed in workplace parking areas, for instance.

AC Charging Station: Cable Attachment Choices

AC charging stations can be equipped with an integrated cable or designed for use with a separate cable. In certain cases, local regulations mandate a specific approach, as seen in Singapore where an integrated cable is obligatory.

An AC charging station with a built-in cable is ideal for situations where the same type of connection will always be used, such as a charging point designated for a specific vehicle.

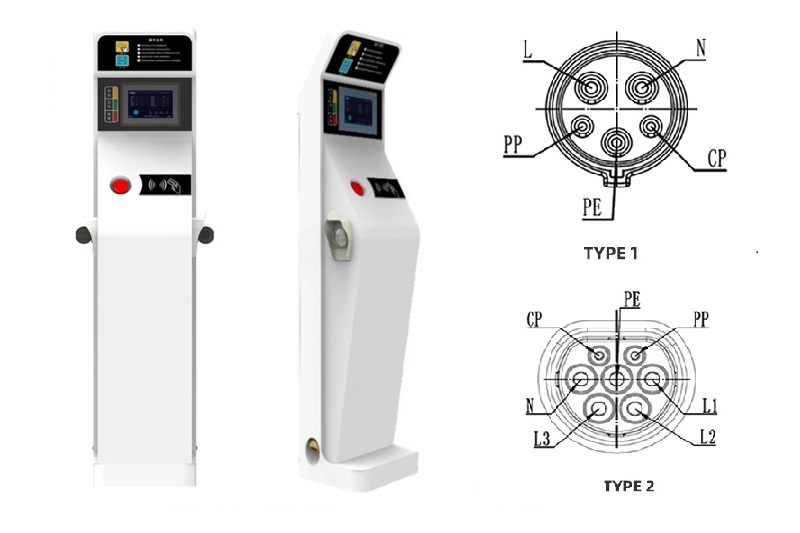

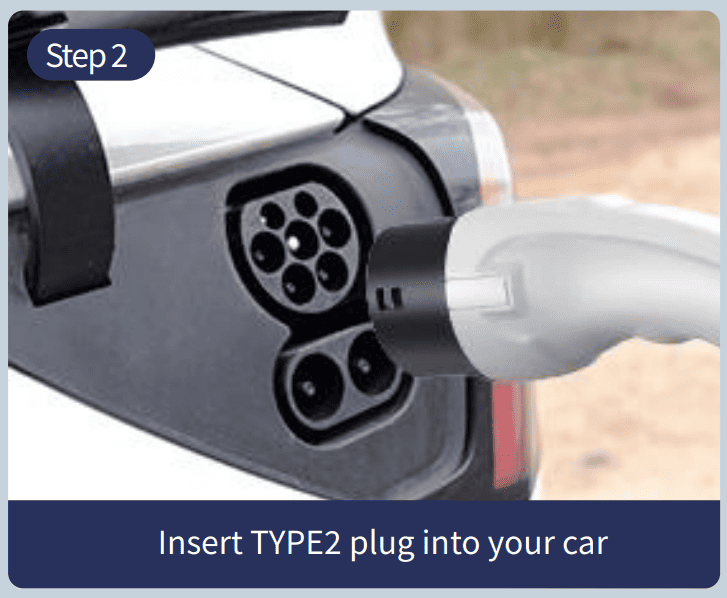

Conversely, an AC charging station without an attached cable offers greater flexibility, catering to various vehicle types. It can feature connectors like type 1, type 2, type 2S, or even a standard domestic plug. In this scenario, EV drivers bring their own personal cables to link the charging station to their vehicles. Certain regions may enforce regulations that specify the type of socket to be used. For instance, in France, the use of a type 2 connector for charging stations is prohibited, and a type 2-S connector is required instead.

Charging stations without attached cables are particularly favored in commercial structures where a diverse array of vehicles may need to charge concurrently.

With the electric vehicle (EV) industry growing at an unprecedented pace – set to represent nearly 30% of new vehicle sales by 2025 in the U.S. and Europe (according to BNEF) – it’s vital for businesses of all kinds to integrate themselves into the emerging electric fueling network. This urgency is particularly evident among fuel retailers, who must modernize their operations to remain relevant and seize revenue opportunities in an evolving mobility landscape.

For any organization, the selection and design of EV charging sites, especially those involving DC fast charging (DCFC), require careful consideration. These sites should be designed to accommodate the growing EV driver community, cater to various vehicle types, ensure accessibility for all drivers, and deliver an exceptional customer experience.

Through years of expertise in developing EV charging sites, ChargersGO has identified essential elements for successful site design. However, before embarking on site design, it’s crucial to understand the foundational aspects to plan for. Questions to address include: How many EVs are registered in your locality and neighboring states? How will this number evolve over time? How can you future-proof your infrastructure investment to accommodate upcoming vehicle models? Where should chargers be strategically placed on the site? What power level is optimal for the chargers? What financial assistance options exist? ChargersGO’s seasoned team can guide you through the evaluation process for your fuel retailing sites, addressing these queries.

- Estimating Electrical Requirements

A primary step in implementing EV charging is ensuring an adequate electrical supply at the site. Collaborating with your charging partner and utility, you can determine the necessary electrical service and power amount based on your site’s location and anticipated charging volume. High-speed DC fast charging demands 480-volt, 3-phase electrical service. Partner with your utility early on to prepare for fast charging.

2. Assessing Available Space

Alongside addressing electrical needs, evaluate the space available at your location and how it aligns with existing infrastructure. As you scale to serve a new community of drivers, consider placements for electrical panels, remote power cabinets, conduit runs, and charging stations. ChargersGO’s experts can assist in site planning, selection, and space management.

3. Addressing Accessibility Regulations

Understanding accessibility mandates within your jurisdiction is crucial when installing DC fast charging. Compliance might involve access aisles, clear pathways to convenience stores from charging stations, and ensuring accessibility for all customers. ChargersGO can guide you through these regulations, ensuring easy access for everyone.

4. Enhancing Visibility and Usability

Effective lighting and signage are essential for charging locations. While your gas fueling forecourt might already have these features, ChargersGO stations are equipped with LED lighting for visibility. Additionally, our mobile app, in-dash integration, and integration with navigation platforms like Apple Maps and Google Maps help drivers locate your site effortlessly.

5. Catering to Different Vehicle Types

As the adoption of EVs expands across passenger and commercial vehicles, consider whether you’ll offer charging for all types of vehicles. Tailor your site layout based on the vehicle sizes and charging port locations. ChargersGO’s expertise can aid you in configuring an efficient setup.

6. Future-Proofing Your Site

Anticipate your next phases of fast charging site development. While newer technology will enable future EVs to charge at higher speeds, it’s essential to accommodate older EVs. ChargersGO’s insights into EV adoption trends can assist in site planning. Design a flexible solution that can grow with demand.

7. Financing and Return on Investment

As more funding opportunities emerge for EV charging projects, a knowledgeable partner is vital to navigate grant requirements and explore financing options. ChargersGO can help identify funding avenues that align with your project goals, ensuring a solid return on investment.

In the rapidly evolving world of EVs, ChargersGO stands ready to guide your fuel retailing sites through these crucial considerations for successful EV charging site design.

Designing an electric vehicle (EV) charger involves a combination of electrical engineering, user experience design, and practical considerations. Here’s a step-by-step guide to help you design an effective EV charger:

1. Understand the Requirements

Determine the type of EV charger you want to design: AC or DC, and the charging power levels (e.g., Level 1, Level 2, DC fast charging).

Research the target market, user needs, and charging habits to inform your design choices.

2. Select Charging Capacity:

Choose the charging capacity based on the power output you intend to offer. Different chargers provide varying charging speeds.

3. Choose Connector Types:

Decide on the types of connectors your charger will support (e.g., Type 1, Type 2, CCS, CHAdeMO) to accommodate different EV models.

4. Electrical Design:

Work with electrical engineers to design the charger’s electrical components, including power conversion, safety features, and connections.

Ensure compliance with safety standards and regulations.

5. User Interface and Experience:

Design a user-friendly interface with clear instructions for starting and stopping the charging process.

Consider integrating touchscreens, LEDs, or indicators to convey charging status and progress.

Include features like contactless payment options and user authentication methods.

6. Physical Design:

Determine the physical form of the charger, whether it’s a wall-mounted unit, pedestal-style, or integrated into existing infrastructure.

Ensure proper ventilation and cooling for efficient operation.

7. Enclosure and Materials:

Choose durable and weather-resistant materials for the charger’s enclosure to withstand outdoor conditions.

Consider using environmentally friendly materials and designs.

8. Accessibility and Safety:

Design the charger with attention to accessibility features for disabled users, including easy reach and visibility.

Implement safety features like emergency shut-off buttons, ground fault protection, and thermal management.

9. Networking and Communication:

Incorporate communication protocols (e.g., Ethernet, Wi-Fi, cellular) to enable remote monitoring, diagnostics, and updates.

Design secure communication channels to protect user data.

10. Compliance and Certification:

Ensure your charger design complies with relevant industry standards, safety regulations, and certification requirements (e.g., UL, CE).

Collaborate with testing laboratories for certification.

11. Testing and Validation:

Prototype and test your charger design under various conditions to ensure functionality, efficiency, and safety.

Conduct usability testing to ensure a seamless user experience.

12. Installation and Integration:

Design the charger to integrate smoothly into various environments, whether residential, commercial, or public spaces.

Consider factors like cable management, mounting options, and power supply requirements.

13. Future-Proofing and Scalability:

Design the charger with scalability in mind to accommodate advancements in EV technology and growing demand.

Plan for software updates and compatibility with emerging EV models.

14. Maintenance and Support:

Design the charger for easy maintenance, with accessible components for repair and replacement.

Develop a support system to address technical issues and user inquiries.

15. Sustainability and Energy Efficiency:

Optimize energy efficiency in your charger design to reduce operating costs and environmental impact.

Consider incorporating renewable energy sources or energy storage solutions.

16. Documentation and User Manuals:

Prepare comprehensive documentation, including user manuals, installation guides, and troubleshooting resources.

Designing an EV charger requires collaboration between electrical engineers, industrial designers, software developers, and regulatory experts. By considering technical requirements, user needs, safety standards, and future trends, you can create a well-designed EV charger that contributes to the growth of the electric vehicle ecosystem.

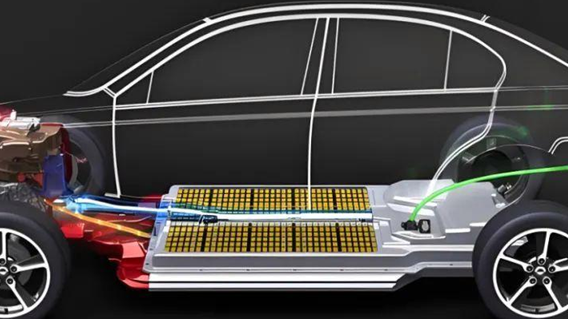

An electric vehicle (EV) charging station consists of several key components that work together to provide a safe and efficient charging experience for electric vehicles. The specific components can vary based on the type of charging station (AC or DC), the charging power level, and any additional features. Here are the common components found in charging stations:

- Power Source:

The power source supplies electricity to the charging station. It could be a local electrical grid connection or a renewable energy source such as solar panels or wind turbines.

- Electrical Supply Equipment:

This includes the transformers, switchgear, and distribution panels that manage the flow of electricity from the power source to the charging equipment.

- Charging Equipment:

The charging equipment handles the actual process of transferring electric power to the vehicle’s battery. It comprises various components, which differ based on the charging level:

a. AC Charging Station (Level 1 and Level 2):

- Charger Unit: Converts AC power from the grid to the appropriate voltage and current required by the vehicle.

- Control and Communication Unit: Manages the charging process, communicates with the vehicle, and monitors safety.

- Cable and Connector: Connects the charging station to the vehicle’s charging port.

b. DC Fast Charging Station (Level 3):

- Power Conversion System: Converts AC power to high-voltage DC power.

- Cooling System: Keeps the power electronics within operating temperature limits.

- Control and Communication Unit: Manages the charging process, communicates with the vehicle, and ensures safety.

- Cable and Connector: Connects the charging station to the vehicle’s charging port.

- User Interface:

The user interface provides information and controls for EV drivers. It can include:

Display: Shows charging status, power level, and any relevant messages.

Keypad or Touchscreen: Allows users to start and stop charging, enter payment details, or access additional services.

RFID Reader or Mobile App Integration: Authenticates users and initiates the charging session.

- Payment System:

If the charging station requires payment for charging services, it will include a payment system such as credit card readers, RFID-based payment methods, or mobile app payment integration.

- Communication and Networking:

Charging stations are often connected to networks to enable remote monitoring, diagnostics, and software updates. This ensures efficient operation and maintenance. Communication methods include Ethernet, Wi-Fi, cellular networks, and Bluetooth.

- Safety and Protection Systems:

Charging stations incorporate safety features to protect users, vehicles, and the charging infrastructure:

Ground Fault Protection: Detects faults and minimizes electrical hazards.

Overcurrent Protection: Prevents damage from excessive current flow.

Temperature Sensors: Monitor the temperature of power electronics and connectors.

Emergency Shut-off Buttons: Allows users or operators to quickly stop charging in case of an emergency.

- Enclosure and Housing:

The charging station is housed in an enclosure that protects its internal components from environmental factors such as weather, dust, and vandalism.

- Cable Management:

Charging stations include mechanisms to manage the charging cables and keep them organized when not in use.

- Mounting Hardware:

- Hardware for securely mounting the charging station to the ground, wall, or other structures.

- Environmental Sensors:

- Some advanced charging stations may include sensors to monitor environmental conditions such as temperature, humidity, and air quality.

- Energy Metering (Optional):

- In some cases, charging stations may include energy meters to track the amount of electricity consumed during a charging session for billing purposes.

These components collectively create a functional and safe charging station that serves the needs of electric vehicle users and contributes to the growth of the EV ecosystem.

Charging stations can be set up either indoors or outdoors. Typically, for outdoor use, they should have at least IP54 level of protection, even though IEC 61851-1 suggests a minimum of IP44. They also usually have an IK protection level of IK10 to guard against impacts. To meet the IEC 61851-1 requirements, chargers need to function at altitudes up to 2000 meters and endure temperatures as low as -25°C in outdoor settings and -5°C indoors.

In real-world scenarios, most charging stations can effectively work within a temperature range of -30°C to +50°C and maintain functionality in relative humidity spanning from 5% to 95%.

Charging Station Output

The output point of a charging station is referred to as a “socket-outlet” when there’s no attached cable. However, it’s termed an “electric vehicle connector” when a cable is attached.

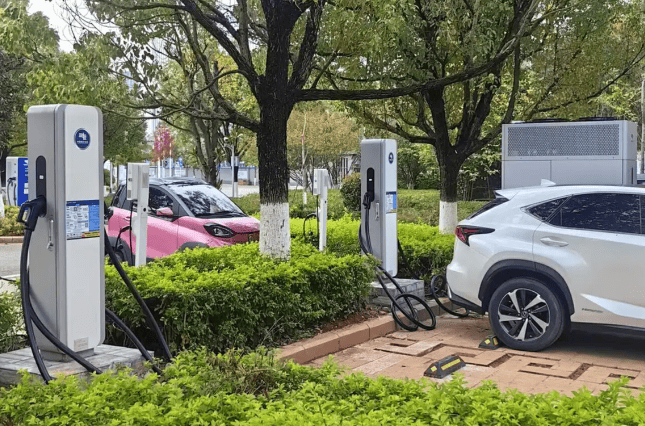

Charging stations can have either single or multiple outputs. In AC charging stations, single outputs are often used for individual single-family homes, while multiple outputs are common in public parking areas. These outputs might be the same type or different.

The benefit of having multiple outputs is that users can potentially charge multiple electric vehicles concurrently. In this scenario, the charging station can distribute its total power among the outputs or allocate full power individually to each output, independent of the others. However, it’s possible that a charging station with multiple outputs might not be able to manage multiple charges simultaneously.

Additionally, charging stations can offer a combination of DC and AC outputs.

Authentication

Charging stations situated in public spaces might include an authentication mechanism, like an RFID reader. This mechanism identifies the user and determines whether to grant access or charge for usage.

Different users can have varying privileges. For instance, VIP users might be given priority access at charging stations with multiple outputs.

Authentication methods can differ. They might be managed locally or remotely through a third-party app. In case of communication loss with the remote app, the charging station should be capable of functioning in an offline mode, potentially allowing all badges, only those present in its cache memory (recently used badges), or none at all.

At-home charging stations usually don’t require authentication mechanisms.

Charging Station Communication

Charging stations can operate independently without external communication. However, they can also support various communication modes like Ethernet, Wi-Fi, 3G/4G, Bluetooth, NFC, and even dry contact interfaces.

External communication serves multiple purposes:

Configuring the charging station settings (e.g., RFID authorization management, parameters)

Maintenance and diagnostics

Remote authorization for charging (when authorization comes from an external system)

Receiving commands for power regulation (e.g., receiving on-peak/off-peak signals from an electronic meter or load management system)

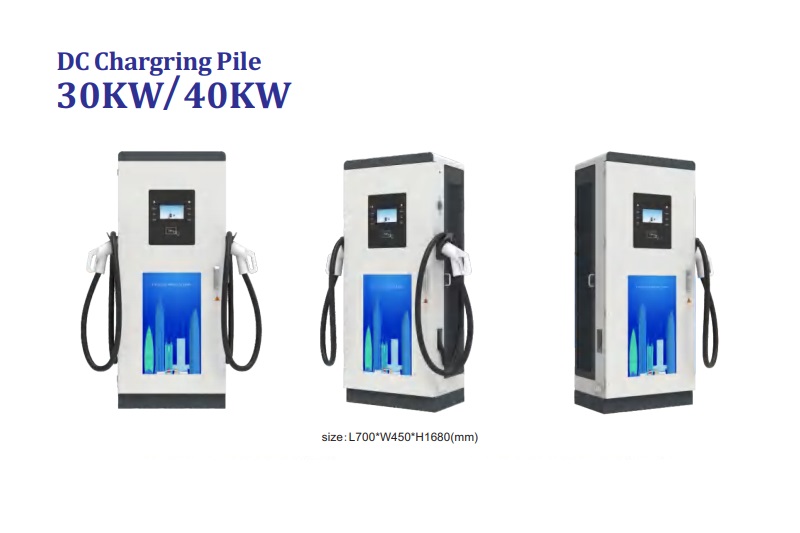

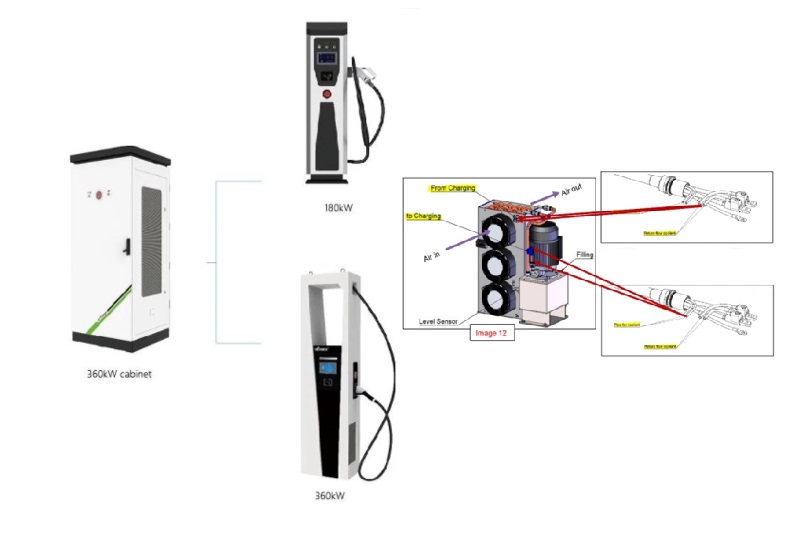

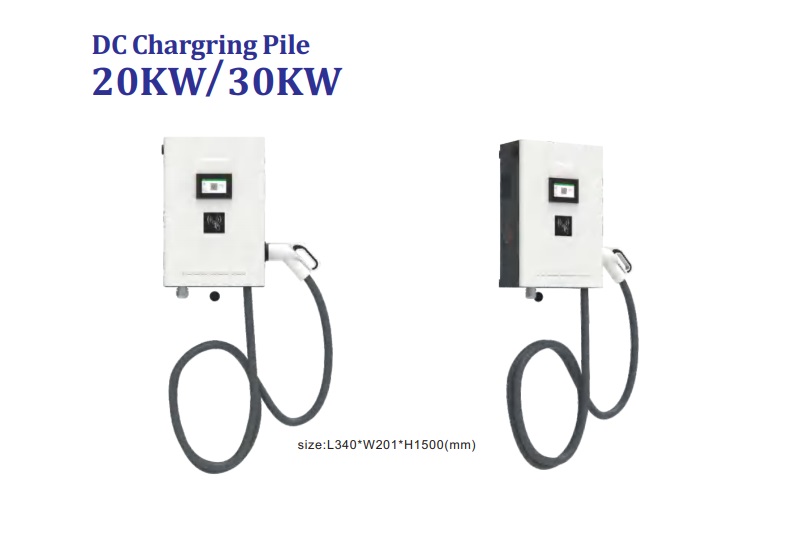

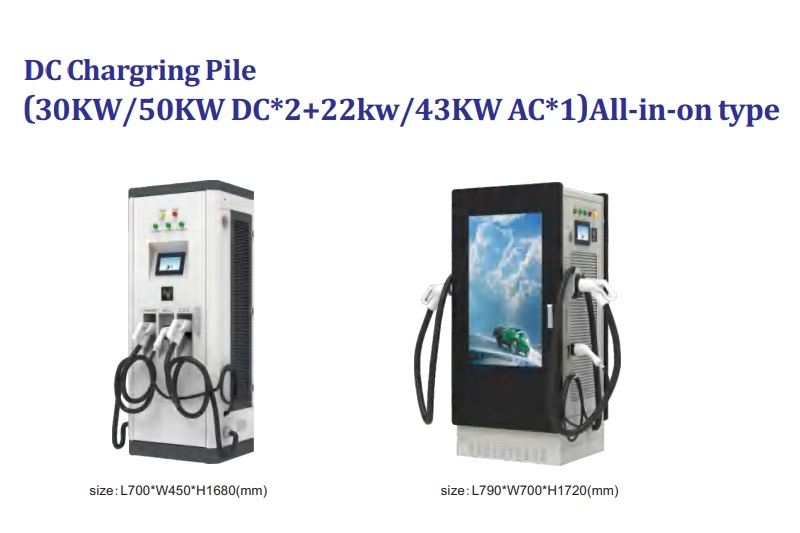

When it comes to Mode 4 fast charging station design, the power delivery of DC charging stations covers a broad spectrum, ranging from 24 kW to over 900 kW with a Combo CCS connector, and up to 400 kW with a CHAdeMO connector.

Fast Charging Station Installation Options

Fast DC charging stations can pack a punch in terms of power, ranging from 24 kW to well over 900 kW. Due to this wide power range, the mechanical blueprint of these charging stations can exhibit considerable diversity from one model to another.

In a broader sense, we can classify them into three primary categories.

The first category involves wall installations, which work well for chargers hovering around 24 kW. As the power capacity increases beyond this point, so does the weight of the charger. Consequently, these installations are usually placed on the floor.

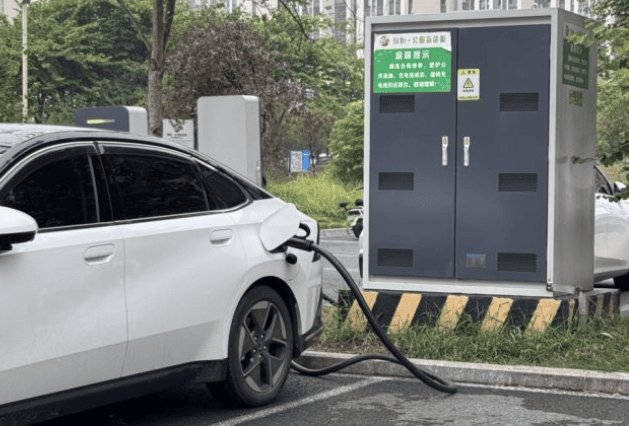

The second design type comprises centralized standalone chargers that stand on the floor.

The third and final category of chargers entails a charging cabinet coupled with one to several satellite charging poles. The cabinet houses power modules that enable dynamic power distribution to each satellite pole. This configuration is commonly employed for DC charging stations with power outputs surpassing 500 kW.

Attached Cable Requirement for Fast Charging Stations

Fast DC charging stations necessitate the use of attached cables for seamless operation.

Designing charging stations involves several key steps to ensure they are functional, accessible, and efficient for electric vehicle (EV) users. Here’s a comprehensive guide to help you design charging stations:

1. Site Assessment and Planning:

Identify suitable locations for charging stations based on high traffic areas, proximity to highways, commercial centers, and residential zones.

Consider the availability of electrical infrastructure and power supply at potential sites.

Evaluate the space available for installation, including parking spots and access pathways.

2. Charging Infrastructure Selection:

Choose between AC (Alternating Current) and DC (Direct Current) charging stations based on the charging speed you want to offer and the types of EVs in your target area.

Decide whether to install Level 1 (slow), Level 2 (medium), or Level 3 (fast) charging stations. Level 3 stations are also known as DC fast chargers and provide the quickest charging.

3. Electrical Capacity and Infrastructure:

Determine the electrical capacity required for the charging stations. Higher-powered stations will need more electrical supply.

Work with utility companies to ensure adequate power capacity and the necessary infrastructure upgrades if needed.

4. Station Placement and Layout:

Design the layout of charging stations to ensure ease of access, parking, and maneuverability for EVs.

Plan for clear signage and wayfinding elements to guide users to the charging area.

Ensure that the placement of charging stations adheres to accessibility regulations and local building codes.

5. Charging Station Features and Accessories:

Choose whether to have standalone charging poles or integrated stations with attached cables.

Include appropriate lighting for visibility during day and night.

Consider adding EV-specific amenities like shelters, benches, and waste disposal facilities.

6. User Experience and Convenience:

Design user-friendly charging interfaces and screens that guide users through the charging process.

Include contactless payment options for easy transactions.

Consider integrating mobile apps for users to find, reserve, and monitor charging stations remotely.

7. Accessibility and Safety:

Ensure compliance with accessibility standards by providing clear pathways, parking spaces, and charging bays for disabled users.

Implement safety features such as emergency shut-off buttons and circuit protection.

8. Networking and Communication:

Incorporate communication protocols to allow remote monitoring, diagnostics, and software updates.

Consider integrating the charging station with management software for data analysis and user support.

9. Future Expansion and Scalability:

Design the charging station infrastructure with scalability in mind to accommodate future demand growth.

Plan for the integration of new technologies and higher charging capacities as EV technology advances.

10. Environmental Considerations:

Implement sustainable practices like using energy-efficient components and renewable energy sources to power the stations.

Design the charging station area to minimize environmental impact and promote clean energy usage.

11. Regulatory and Permitting Compliance:

Ensure that the charging station design adheres to local, regional, and national regulations and codes.

Obtain the necessary permits and approvals before installation.

12. Maintenance and Support:

Plan for regular maintenance and repairs to keep the charging stations operational.

Consider establishing partnerships with service providers to ensure timely support.

Remember that successful charging station design requires collaboration with electrical engineers, architects, urban planners, and relevant authorities. Tailor your design to the specific needs of your target users and the local environment to create a convenient and efficient charging experience for EV drivers.

An electric vehicle (EV) charging station is a dedicated place where electric cars and other EVs can be charged with electricity to power their batteries. Just like gas stations provide fuel for conventional cars, charging stations provide the energy needed for EVs to run.

The concept is quite similar to plugging in your phone or laptop to charge, but on a larger scale. Charging stations come in different types, offering varying levels of charging speed. Some are like “fast-food” chargers, giving a quick boost of energy to get you on your way, while others are more like “dining-in” chargers, providing a fuller charge over a longer period.

These stations have special equipment that converts the electricity from the power source (like the electrical grid or solar panels) into a form that the EV’s battery can use. When you connect your EV to a charging station using a cable, the charger feeds electricity into your vehicle’s battery, allowing you to drive farther on electric power.

Charging stations also often have user-friendly interfaces that help you start and stop the charging process, and they might offer payment options, so you can pay for the electricity you use. With the growth of electric vehicles, charging stations are becoming more common in public places, making it easier for EV drivers to recharge their vehicles while they’re out and about.

EV Chargers for Sale:

ChargersGO Factory Informations

Our EV Charger Factory Introduction:

| Business Type: | Manufacturer/Factory | Main Products: | EV Charger |

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

ChargersGO Factory is a reputable manufacturer specializing in Electric Vehicle (EV) Chargers. Our extensive product range includes slow chargers, fast chargers, DC EV Chargers, AC EV Chargers, commercial EV Chargers, home chargers, and EV chargers of various levels, including level 1, level 2, and level 3. All our products adhere to strict China GMP design standards, ensuring top-notch quality and performance. Additionally, we take pride in securing various certifications to ensure the reliability and safety of our chargers.

Business Philosophy:

“Quality is the main policy of sales” and “integrity is the principle of success” are the business philosophy of our people. We carry out one-year warranty, lifelong maintenance service, with technical consultation and other services, and long-term supply of equipment. Welcome new and old customers to negotiate cooperation!

Production Process:

The production of an Electric Vehicle (EV) charger entails a meticulous process aimed at delivering top-notch quality, safety, and performance. It involves several essential stages:

- Design and Engineering: Expert engineers and designers collaborate to create a comprehensive blueprint for the EV charger. They consider factors like power capacity, safety features, charging protocols, and compatibility with various electric vehicle models.

- Component Sourcing: After finalizing the design, the production team sources high-quality components and materials required for the charger. These may include circuit boards, connectors, casing materials, power modules, and safety components, ensuring reliability and longevity.

- Circuit Board Assembly: The heart of the EV charger lies in its circuit board, which controls the charging process and ensures safety. Advanced Surface Mount Technology (SMT) machines precisely place electronic components on the circuit board, with certain elements carefully assembled by skilled technicians.

- Casing and Enclosure: The charger’s casing is vital for protecting against external elements and ensuring user safety. Durable materials like aluminum or robust plastics are often used, and manufacturing techniques like injection molding create the charger’s sturdy enclosure.

- Quality Control: Rigorous quality control checks are conducted throughout the production process to identify any defects or inconsistencies. Chargers undergo multiple tests to ensure functionality and safety compliance. Quality control specialists meticulously examine each unit to meet industry standards.

- Safety Testing and Certifications: Before the chargers hit the market, they undergo rigorous safety testing and certifications. Electrical safety, thermal, and environmental tests ensure the chargers can perform reliably in diverse conditions.

- Final Assembly and Packaging: Successfully passing all tests and certifications, the chargers proceed to final assembly and packaging. They are carefully packaged with user manuals and any necessary accessories.

- Distribution and Installation: The chargers are distributed to retailers, charging network operators, or directly to end customers. Upon receiving them, they are installed at charging stations or offered to electric vehicle owners for home charging.

- Customer Support and Maintenance: Manufacturers provide ongoing customer support and maintenance services to ensure the chargers continue to perform optimally. This includes troubleshooting assistance, firmware updates, and periodic inspections.

By adhering to this comprehensive production process, EV charger manufacturers ensure that their products are efficient, reliable, and safe, contributing to the broader adoption of electric vehicles and sustainable transportation.

By following a well-structured production process and adhering to strict quality standards, manufacturers can produce high-quality EV chargers that contribute to the growth of electric mobility and a greener, sustainable future.

Certifications:

Small EV Charger Packing:

Retail and Wholesale Packaging of Small EV Chargers for Shipment

Retail Small EV Charger Shipment:

For retail orders, Small EV Chargers are shipped using express shipping methods.

Wholesale Small EV Charger Shipment:

For wholesale orders, Small EV Chargers are carefully packed in export fumigation-free wooden cases, suitable for bulk shipments or container transportation.

- Packing Small EV Chargers for Sea Shipment:

When preparing Small EV Chargers for sea shipment, utmost care is taken to ensure their protection from potential damage during transit. Here are the standard steps followed by manufacturers when packing Small EV Chargers for sea shipment: - Cleaning and Drying: Prior to packing, each charger is thoroughly cleaned and dried to prevent any moisture or debris that could cause harm during transit.

- Disassembly: Where possible, the charger is disassembled into its individual components, reducing its overall size and facilitating easier packing.

- Protective Wrapping: The charger is wrapped in a layer of protective material, such as bubble wrap or foam, shielding it from scratches and potential impacts during transit.

- Sturdy Packaging: The wrapped charger is then placed into a sturdy box specifically chosen to match the charger’s size and weight. These boxes are constructed from durable materials, such as corrugated cardboard or plywood, capable of withstanding the demands of sea transportation.

- Cushioning: Adequate packing material, such as packing peanuts or air pillows, is added inside the box to provide cushioning and prevent the charger from shifting during transit.

- Secure Sealing: The box is securely sealed using high-quality packing tape, ensuring it remains tightly closed throughout the journey.

- Proper Labeling: Each box is clearly labeled with essential information, including the charger’s name, weight, destination address, and contact details.

The primary objective of these packing measures is to safeguard the Small EV Chargers from any potential damage during sea shipment, ensuring they arrive at their destination in optimal condition. Employing correct packing procedures and utilizing high-quality materials minimizes the risk of harm during the journey.

Packing a Large EV Charger for Sea Shipment: Ensuring a Safe Voyage

Packing a large EV charger for sea shipment is a meticulous and demanding process, but with meticulous planning and precision, it can be done effectively to guarantee its safe arrival at the destination. Below are the essential steps a manufacturer may undertake when preparing a large machine for sea shipment:

- Comprehensive Cleaning and Preparation: Prior to packing, the EV charger undergoes thorough cleaning and preparation. All fluids, such as oil or coolant, are drained, and any detachable parts are removed.

- Disassembly for Efficiency: If feasible, the machine is disassembled into its component parts, reducing its overall size and easing the packing process. Each part is carefully labeled and numbered for easy reassembly at the destination.

- Protection for Fragile Parts: Delicate or fragile components are meticulously wrapped in protective material, such as bubble wrap or foam, to shield them from potential damage during transit.

- Custom Crate Construction: A custom-built crate is crafted around the machine, providing a secure and robust enclosure. The crate is constructed using durable materials, like plywood, and tailored to snugly fit the machine. Braces or supports are incorporated to prevent any movement during transit.

- Cushioning Material Addition: The crate is thoughtfully filled with cushioning material, such as packing peanuts or air pillows, to offer additional protection and prevent the machine from shifting during its voyage.

- Secure Fastening: The EV charger is firmly fastened within the crate, ensuring it remains in place throughout the journey. Straps, bolts, or other reliable fasteners are utilized to hold the machine securely.

- Sealing and Clear Labeling: The crate is securely sealed using high-quality packing tape, and it is clearly labeled with essential information, including the machine’s name, weight, and relevant details. The destination address and contact information are prominently marked for easy identification.

Overall, packing a large EV charger for sea shipment demands precision and adherence to proper procedures. Employing high-quality materials and meticulous attention to detail ensures the machine’s safe and intact arrival at its intended destination. For added assurance, consulting a professional packing and shipping company can guarantee the machine is expertly packed and ready for its sea journey.

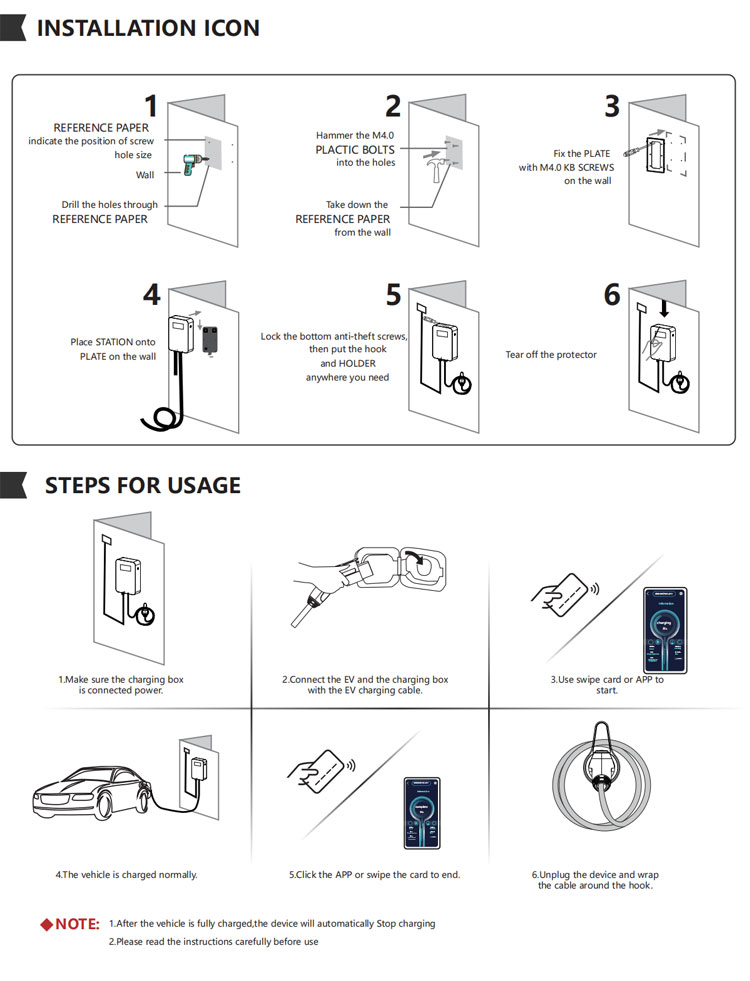

Installing an Electric Vehicle (EV) Charger requires careful planning and consideration to ensure a safe and efficient charging experience. Here is a step-by-step guide to the installation process:

- Site Assessment: The first step is to assess the site where the EV charger will be installed. Factors to consider include the proximity to the electrical panel, available space, and access to the parking area. Additionally, the electrical capacity of the property must be evaluated to ensure it can handle the charger’s power requirements.

- Selecting the Charger: Choose the appropriate EV charger based on your vehicle’s charging needs and the electrical infrastructure available at the site. There are various options, including Level 1 chargers (120-volt outlets), Level 2 chargers (240-volt outlets), and Level 3 chargers (fast DC charging stations).

- Obtaining Permits: Check local regulations and obtain any necessary permits for the installation. Some areas may require electrical permits or compliance with specific building codes.

- Electrical Panel Upgrades (if required): Depending on the chosen charger and the available electrical capacity, an electrical panel upgrade may be necessary to accommodate the charger’s power requirements. A licensed electrician can help with this process.

- Running Wiring and Cabling: Properly run the required wiring and cabling from the electrical panel to the charging location. It’s essential to use appropriate cable gauges and follow safety standards to ensure the charger receives the correct power supply.

- Mounting the Charger: Securely mount the EV charger on the wall or a suitable stand, ensuring it is positioned at the desired charging location and easily accessible for EV owners.

- Connecting the Charger: Carefully connect the charger to the wiring and cabling, following the manufacturer’s instructions and safety guidelines. Double-check all connections for accuracy and tightness.

- Testing and Activation: Before commissioning the charger, perform thorough testing to ensure it functions correctly and safely. Test the charger with an electric vehicle to ensure it can initiate and complete the charging process.

- User Training: If the EV charger is part of a public or shared charging station, provide user instructions and any necessary training to ensure users can operate the charger correctly.

- Signage and Markings: Install appropriate signage and markings to indicate the EV charging station’s location and any usage instructions.

- Ongoing Maintenance: Regularly inspect and maintain the EV charger to ensure it remains in optimal working condition. Periodic inspections by a qualified technician can help identify and address any potential issues promptly.

It is crucial to have a licensed electrician perform the installation to ensure compliance with electrical codes and safety standards. Additionally, some EV charger manufacturers offer professional installation services, which can provide peace of mind and ensure a smooth and trouble-free installation process.

Applications of EV Charger:

- Highway and Travel Routes: Level 3 chargers are strategically placed along highways and major travel routes to offer EV drivers the ability to quickly recharge their vehicles during long trips. This helps alleviate range anxiety and encourages EV adoption for long-distance travel.

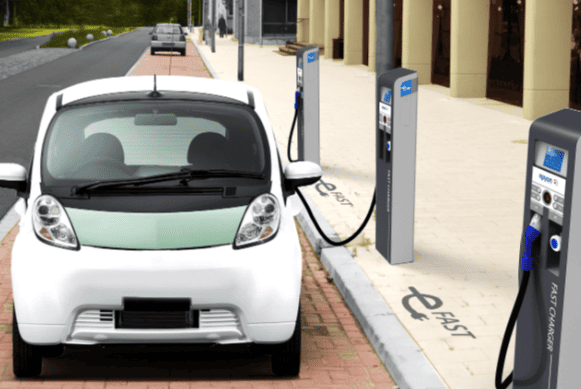

- Urban Charging Hubs: Level 3 chargers are often installed in urban areas, city centers, and public parking lots. These locations cater to drivers who need to recharge their vehicles quickly while running errands or during short stops.

- Commercial Fleets: Businesses with electric vehicle fleets benefit from Level 3 chargers, as they allow multiple vehicles to be rapidly charged, enabling efficient operation without prolonged downtime.

- Public Charging Stations: Level 3 chargers are a valuable addition to public charging networks, providing a convenient option for EV drivers who require fast charging while shopping, dining, or engaging in other activities.

- Transit Stations: Charging stations equipped with Level 3 chargers can be found at transit stations, providing rapid charging solutions for electric buses, shuttles, and other forms of electric public transportation.

- Fast-Charging Corridors: Some regions establish fast-charging corridors equipped with Level 3 chargers to facilitate long-distance travel for EV drivers, encouraging intercity and interstate journeys.

- Airports: Airports often install Level 3 chargers in their parking facilities to cater to travelers who require quick charging upon arriving or before departing.

- Hotel and Lodging Facilities: Hotels and lodging facilities may offer Level 3 chargers to accommodate guests with electric vehicles who need a fast recharge during their stay.

- Rental Car Services: Car rental companies can incorporate Level 3 chargers into their fleets to ensure that rented electric vehicles are promptly recharged for the next customer.

- Workplace Charging: Some workplaces install Level 3 chargers to provide employees with the option of a fast charge during working hours, supporting their EV adoption.

In essence, Level 3 EV chargers are vital for scenarios where EVs need to be charged quickly and efficiently to meet the demands of busy individuals, travelers, commercial operators, and public transportation services.

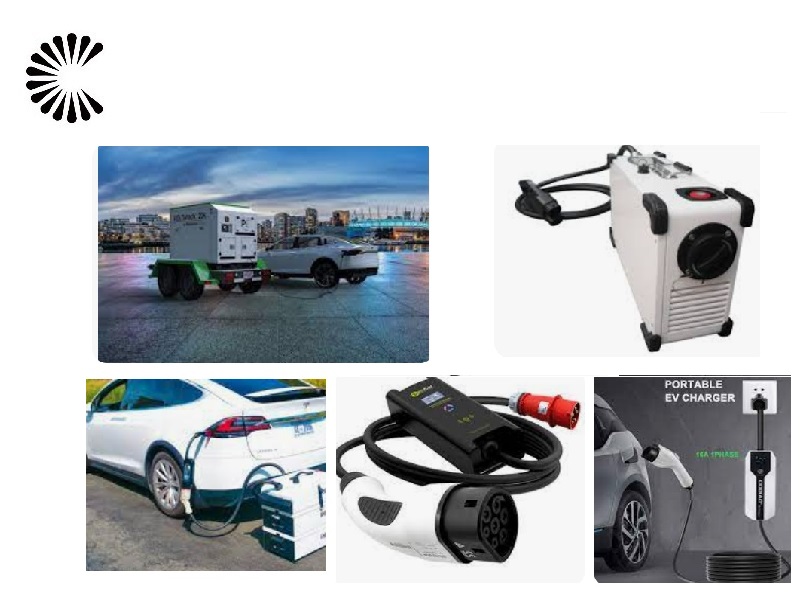

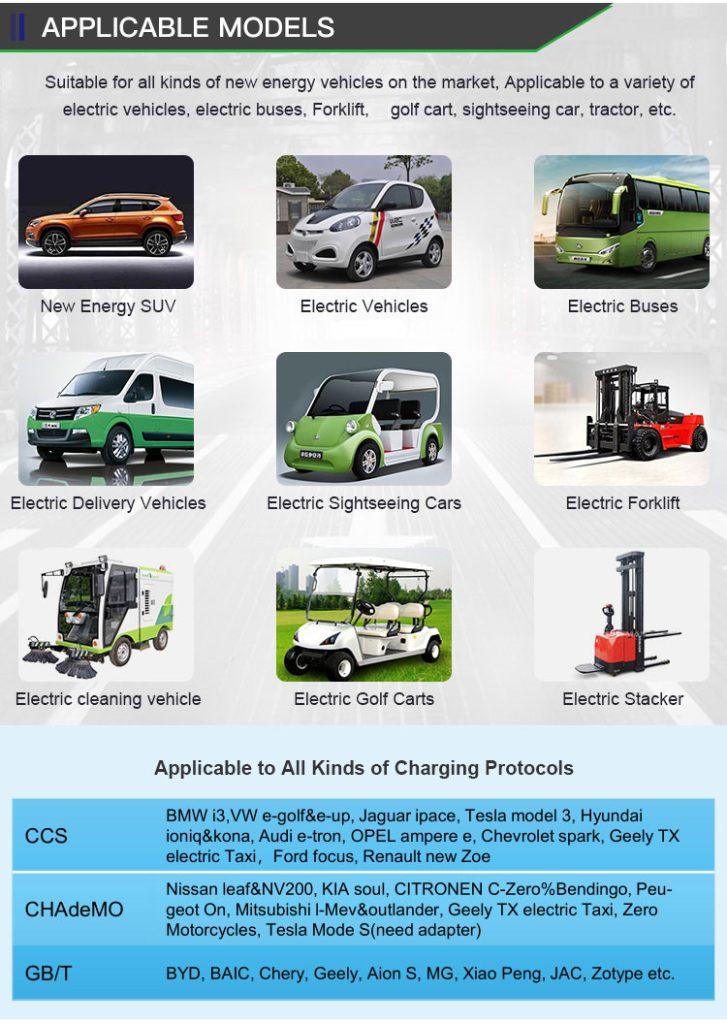

It is appplicable for all kinds of charing protocols, Suitable for all kinds of new energy vehicles on the market,Applicable to a variety of electric vehicles, electric buses,Forklift,golf cartsightseeing cartractor, etc.

| CHAdeMO | Nissan leaf&NV200, KIA soul, CITRONEN C-Zero%Bendingo, Peu geot On, Mitsubishi l-Mev&outlander, Geely TX electric Taxi,Zero Motorcycles, Tesla Mode S(need adapter) |

| CCS | BMW i3,VW e-golf&e-up, Jaguar ipace, Tesla model 3, Hyundai ioniq&kona, Audi e-tron, OPEL ampere e, Chevrolet spark, Geely TX electric Taxi,Ford focus, Renault new Zoe |

| GB/T | BYD, BAIC,Chery, Geely, Aion S, MG, Xiao Peng, JAC, Zotype etc. |

EV Charger Wholesale Manufacturer In China

Charging an Electric Vehicle (EV) involves refilling the energy stored in the EV’s battery. This is done by connecting the EV to a charging station or charger. ChargersGO is the manufacturer and wholesaler for EV Charger. Please feel free to contact with us.