Cost to install electric car charger

Cost to install electric car charger . Due to variations in labor costs, regulatory requirements, grid characteristics, and subsidy policies, the cost of installing an electric car charger varies greatly between nations and regions. A thorough analysis based on the most recent 2025 data is provided below, along with regional comparisons and cost-optimization tactics:

Global Cost Structure Comparison for Core Markets

North America (U.S. and Canada)

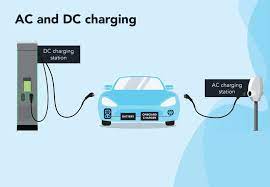

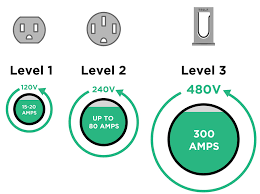

The installation cost for a home charging station (Level 2) in North America ranges from $1,500 to $4,000, including equipment and labor. For commercial DC fast charging stations (DCFC), the cost can soar to $40,000–$200,000 per unit, depending on power capacity and infrastructure requirements. In the U.S., federal tax credits cover up to 30% of installation costs (capped at $1,000), while states like New York offer additional subsidies of up to $3,000. This can reduce the net cost of a home charger to as low as $500. However, older homes often require electrical panel upgrades, adding $2,000–$5,000 to the total expense. Commercial installations face higher costs due to the need for transformers, trenching, and compliance with spacing regulations (e.g., California’s NEVI program mandates charging stations every 50 miles).

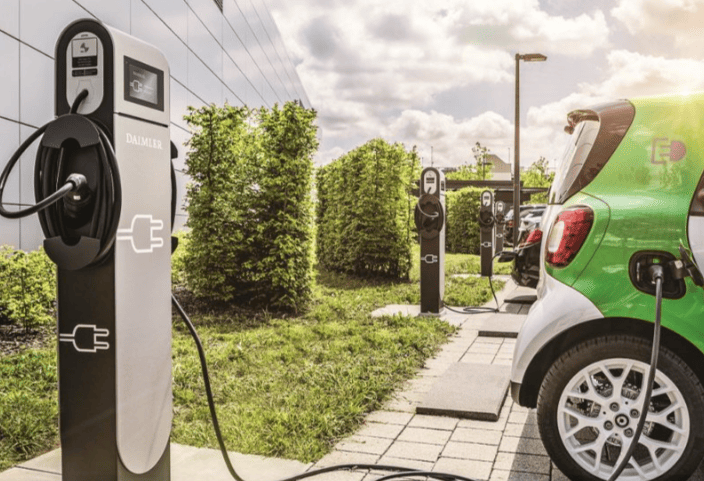

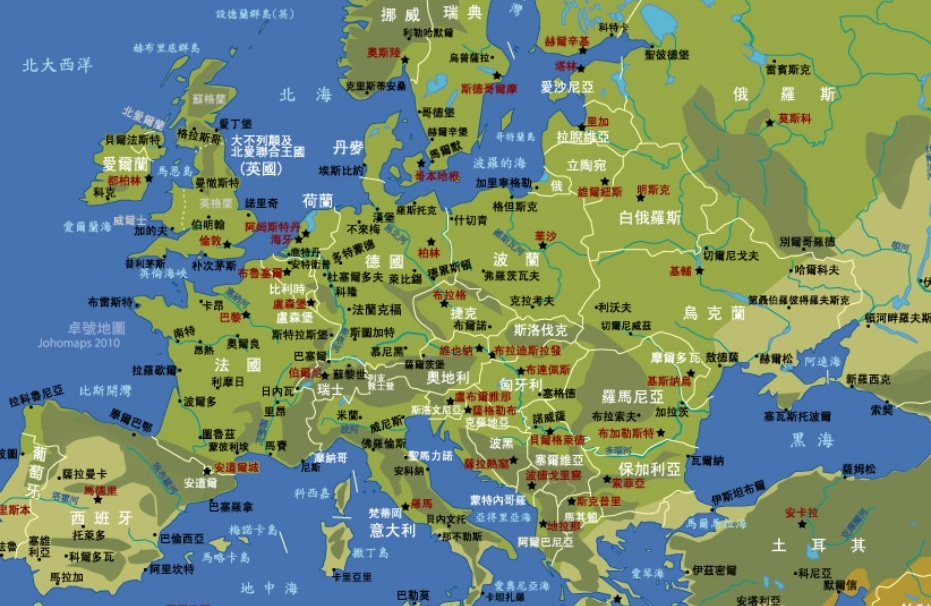

European Union

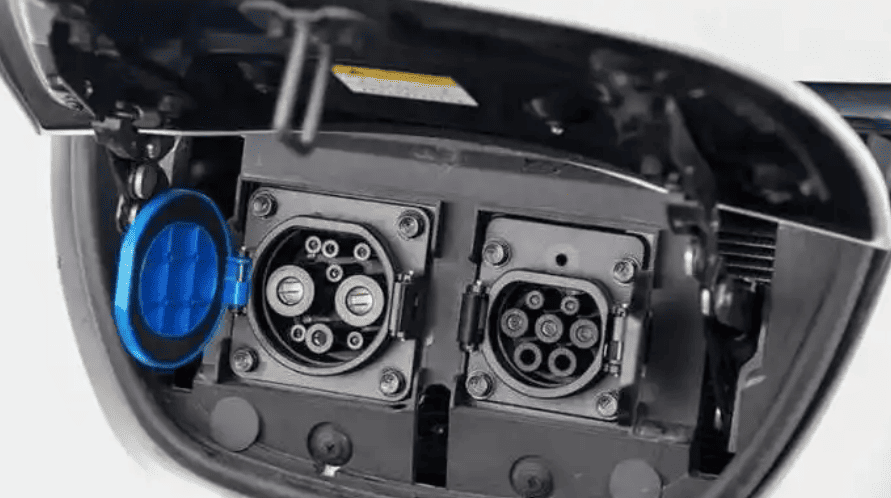

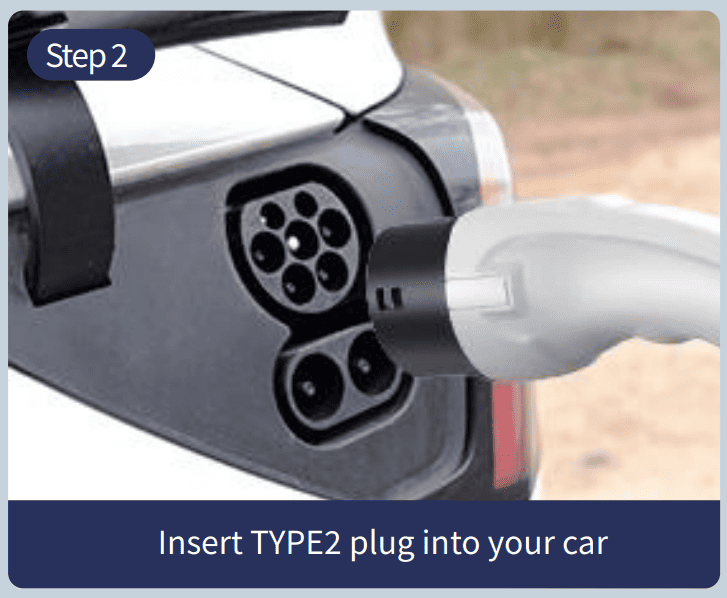

In the EU, home charger (Type 2) installation costs range from €1,400 to €3,300, including equipment and labor. Countries like Germany offer subsidies of €900 per private charger, covering up to 50% of the cost. Commercial high-power charging (HPC) stations cost €15,000–€80,000 per unit, with installation accounting for 40%–60% of the total due to grid upgrades and fire safety requirements. France provides subsidies of €30,000 per HPC station to support highway networks. The EU’s strict regulations, such as GDPR-compliant data storage, add $800 per charger for edge computing modules.

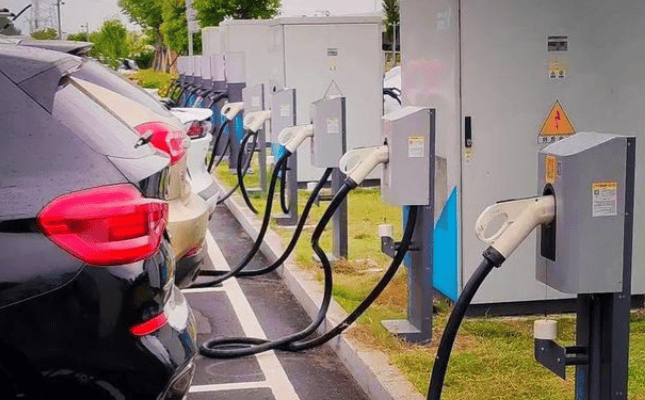

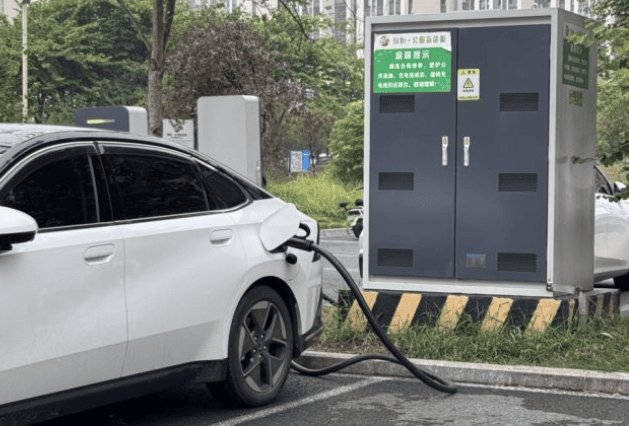

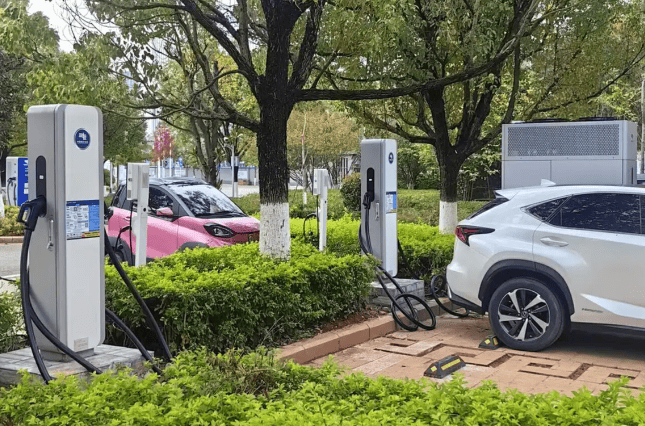

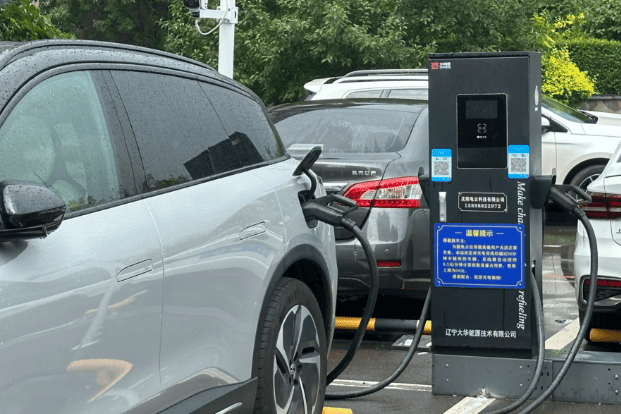

Asia-Pacific

In China, home charger installation costs ¥1,300–¥5,000, with commercial DC fast chargers ranging from ¥80,000 to ¥250,000. The government’s “New Infrastructure” policy has reduced costs by 20% through subsidies. Japan’s home chargers cost ¥100,000–¥250,000, with Tokyo subsidizing 50% of the expense. Southeast Asia has lower costs: home chargers cost $80–$230, while commercial 50kW stations cost $8,000–$15,000. Countries like Vietnam offer subsidies of $100 per charger for electric motorcycles.

Key Cost Drivers and Localization Strategies

Grid Upgrade Costs

In North America, outdated electrical panels require upgrades costing $2,000–$5,000. In the EU, three-phase power installation adds €1,200–€3,000, while Southeast Asia requires voltage stabilizers ($200–$500) due to unstable grids. Subsidies for grid upgrades are available in regions like Indonesia (50% coverage).

Regulatory and Certification Costs

Safety certifications (e.g., UL in the U.S., CE in the EU, PSE in Japan) add $5,000–$10,000 per charger model. Data compliance rules, such as GDPR in the EU, require additional hardware for local data storage, increasing costs by $800 per unit.

Labor Costs

Labor rates vary widely: $80–$120 per hour in the U.S., $60–$90 in the EU, and $5–$15 in Southeast Asia. However, regions with lower labor costs may require additional training and certification, offsetting some savings.

Subsidy Policies

Subsidies play a critical role in reducing costs. The U.S. IRA Act offers tax credits of 30% for commercial chargers (up to $100,000 per unit), while the EU’s MOVES III program covers 70% of costs for small businesses. China’s subsidies focus on ultra-fast charging stations, covering 30% of construction costs.

Cost Optimization Paths and Technology Trends

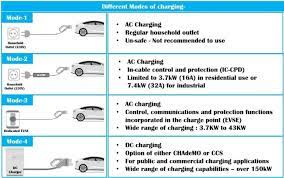

Modular Hardware Design

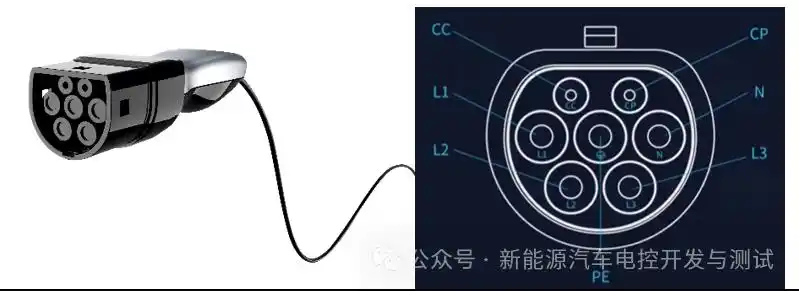

Multi-protocol chargers (supporting CCS, CHAdeMO, and GB/T) reduce certification costs by 30%. Liquid cooling technology (e.g., Tesla’s V4 Supercharger) shrinks hardware size by 50%, lowering installation space requirements.

Standardized Installation Processes

Prefabricated components (e.g., ABB’s Plug-and-Charge kits) cut on-site labor time by 40%. AI-assisted design tools (e.g., Autodesk Revit) optimize cable routing, reducing material waste by 15%.

Energy Management Integration

Solar-storage-charging systems reduce grid dependency and lower levelized energy costs (LCOE) by 25%. Vehicle-to-grid (V2G) technology allows users to earn $0.12/kWh by supplying power back to the grid, potentially recouping installation costs within five years.

Regional Market Entry Recommendations

North America

Focus on NACS-compatible home chargers with solar input modules. Manufacture in Mexico to avoid IRA localization requirements and leverage tariff exemptions.

European Union

Develop V2G-enabled smart chargers compliant with EN 50610 standards. Partner with local governments to access subsidies like the “Just Transition Fund,” covering 70% of rural installation costs.

Southeast Asia

Offer IP67-rated universal chargers (12V/24V) with emergency start functions. Sell via e-commerce platforms (e.g., Shopee, Lazada) in bundles with battery diagnostics, priced at $80–$120.

Emerging Markets (e.g., India, Africa)

Deploy solar-compatible chargers with wide voltage input (100–240V). Use lead-acid battery storage (40% cheaper than lithium) for power-deficient areas.

Risks and Countermeasures

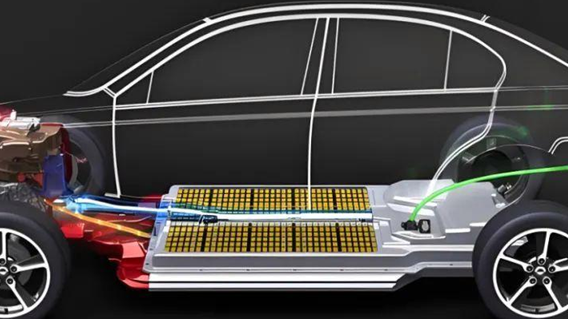

- Raw Material Price Volatility: Lithium price fluctuations (±25%) can impact costs. Adopt LFP batteries for storage (30% cheaper).

- Policy Changes: EU carbon tariffs (CBAM) may increase export costs. Optimize production using recycled materials (e.g., aluminum casings).

- Technological Shifts: Solid-state batteries may require new charging protocols. Design modular hardware with upgradeable components.

Conclusion

Regional regulations and technology developments will influence the cost of installing electric vehicle chargers in 2025. Southeast Asia uses Chinese supply chains to keep commercial fast chargers under $10,000, while U.S. subsidies can reduce home charger costs to less than $500. Manufacturers have to take user needs, subsidy programs, and local grid conditions into account. Retaining competitiveness requires tactics like energy integration, localized production, and modular design. Successful strategies in international markets are exemplified by businesses such as Duotone (liquid cooling technology) and Newman (multi-functional integration).

Comprehensive Analysis of Home EV Charger Installation Costs

1. Core Equipment Procurement Costs

Brand differentiation significantly impacts prices, with international brands typically 30%–50% more expensive than domestic alternatives. Power rating also affects costs: 3.5kW basic models range from $280–$490, 7kW models cost $560–$1,120, and 22kW high-end models exceed $2,100.

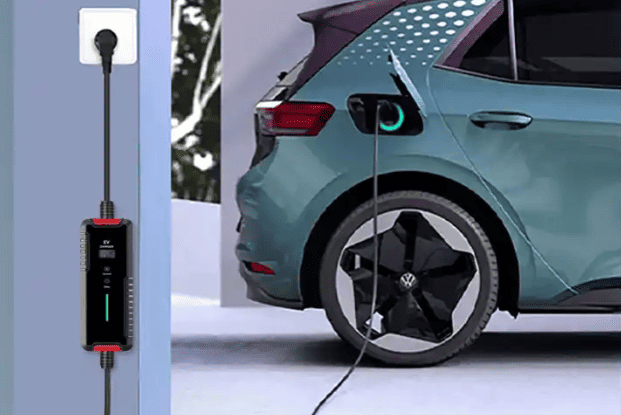

2. Engineering Implementation Expenses

Standard installation (within 30 meters of the electrical meter) costs $210–$420. Complex projects (e.g., cable trenching, grid upgrades) can increase costs to $700–$1,400. Labor rates in first-tier cities are 40%–60% higher than in smaller cities.

3. Additional Cost Considerations

Extra cable beyond 30 meters incurs $7–$11 per meter. Grid upgrades in older neighborhoods add $280–$700. Some cities charge $28–$70 for electricity plan reviews.

4. Key Price Determinants

Every 10 meters of additional cable increases costs by 8%–12%. High protection ratings (e.g., IP65) add $70–$210. Smart features (e.g., APP control) raise prices by 15%–25%.

To make informed decisions, consumers should seek professional assessments and consider long-term usage needs. For product comparisons, platforms like Baidu’s “Ai Cai Gou” offer valuable insights.

This expanded analysis provides a thorough overview of the costs, trends, and strategies associated with EV charger installation, helping consumers and businesses navigate the evolving landscape.